Casting sand core hot box and sand core molding method

A molding method and a hot core box technology are applied in the casting sand core hot box and sand core forming, sand core hot box and molding fields, which can solve the problem that the shape of the designed sand core cannot be achieved, the normal production is affected, and the heat transfer speed is slow. and other problems to achieve the effect of reducing porosity defects, shortening molding time, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In order to better understand and implement the technical solutions of the present invention, some embodiments of the present invention are provided here. These embodiments are for better explaining the technical solutions described in the present invention, and do not constitute any form of limitation to the present invention.

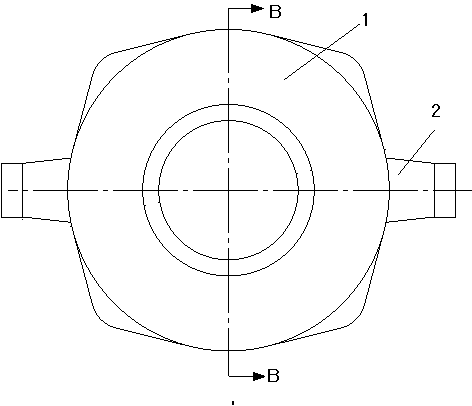

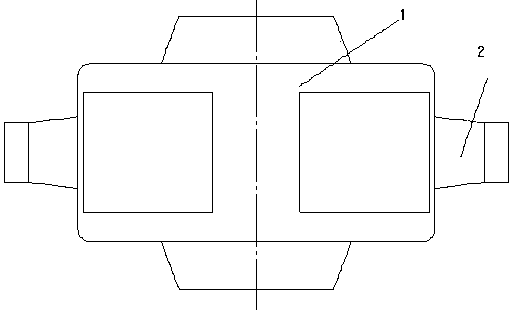

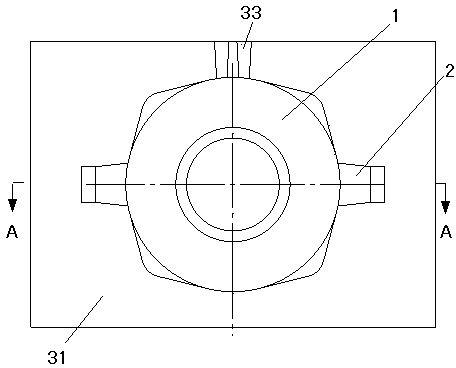

[0033] The present invention is a casting sand core hot core box and a molding method for casting sand cores, the following reference Figure 1-Figure 6 The hot core box of the present invention is described, wherein the casting sand core hot box includes a moving film 31 and a static mold 32 of the sand core hot box, and the side of the hot core box is provided with a sand injection port 33 and an exhaust port. The middle of the cavity of the movable mold 32 or the static mold 31 is fixedly connected with the end of the cone rod 35, the long part of the cone rod 35 is a cone cylinder, the long part of the cone rod 35 is connected with a filler ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com