Control method of soft-reduction depressed region of wide and thick plate continuous casting blank

A control method and soft reduction technology, which is applied in the field of soft reduction control of continuous casting technology, can solve problems such as uneven growth of slab shells, degradation of rolling plates, and transverse cracks at corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

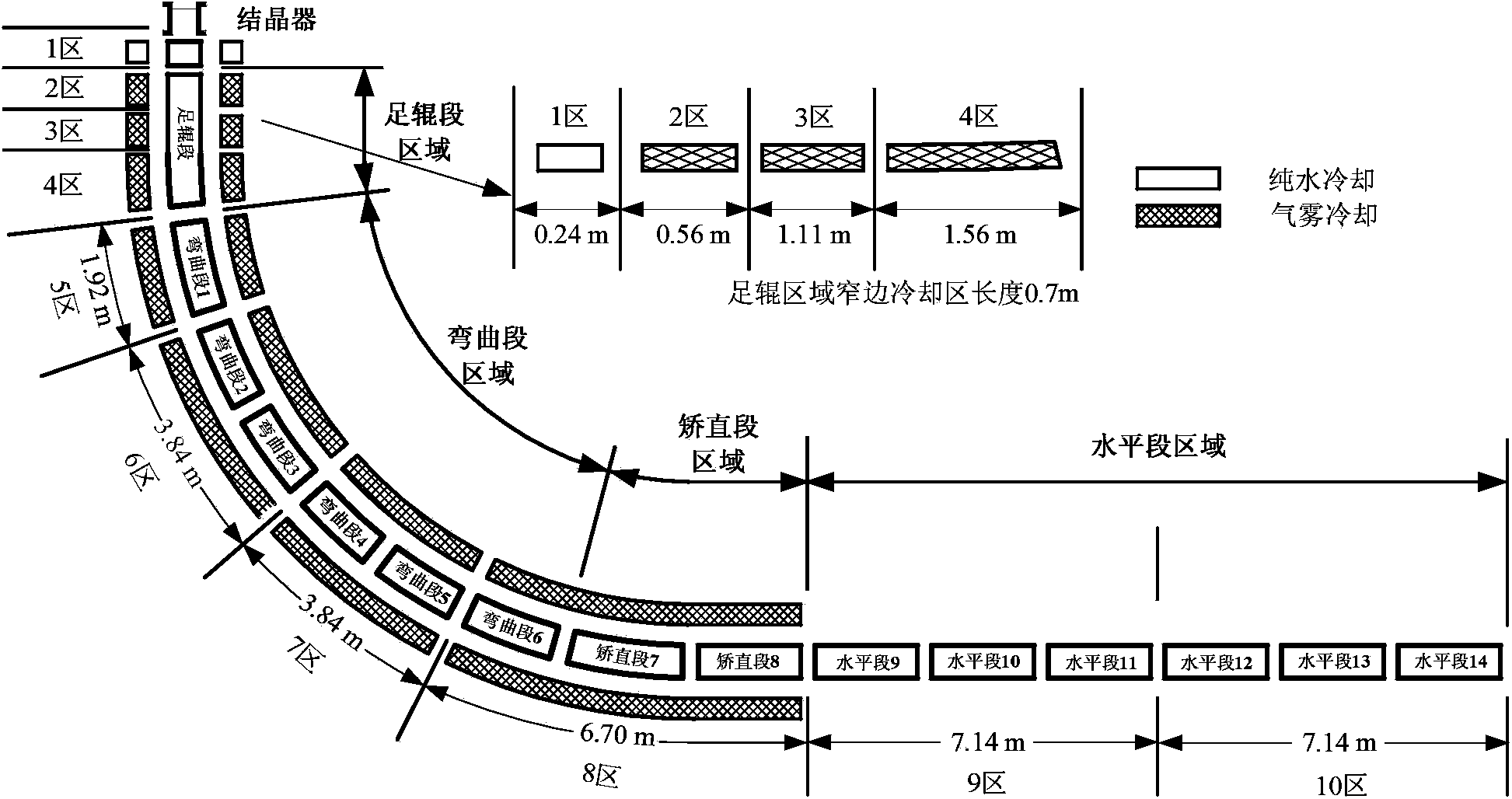

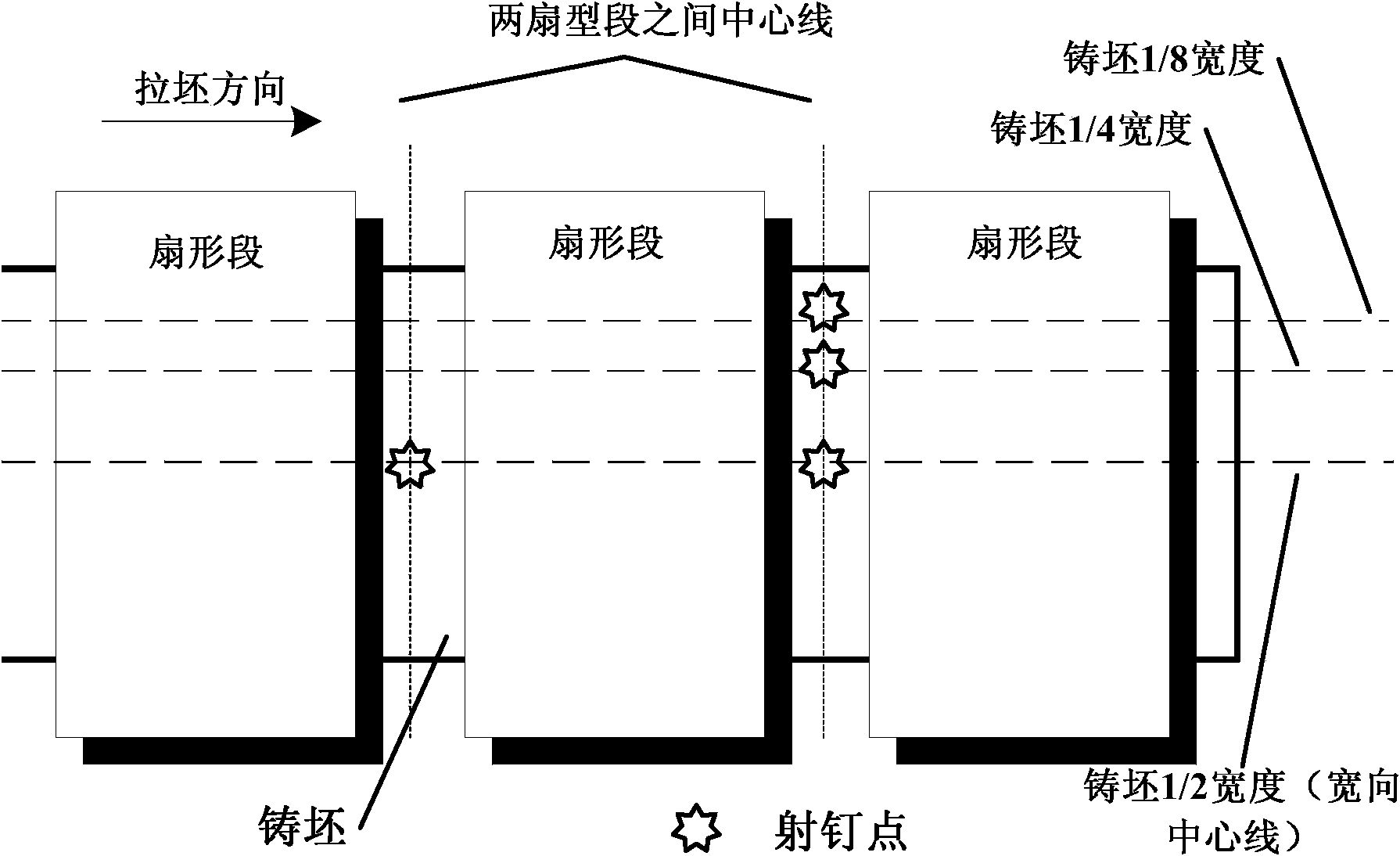

Method used

Image

Examples

Embodiment 1

[0045] The selected peritectic steels with cross-sectional dimensions of 2100mm×250mm, 1600mm×300mm and 2300mm×180mm respectively, the target composition contains C0.17%, Si0.15%, Mn0.60%, P≤0.015% by weight percentage, S≤0.015%, the balance is Fe; casting temperature is 1545°C, casting speed is 0.9~1.1m / min;

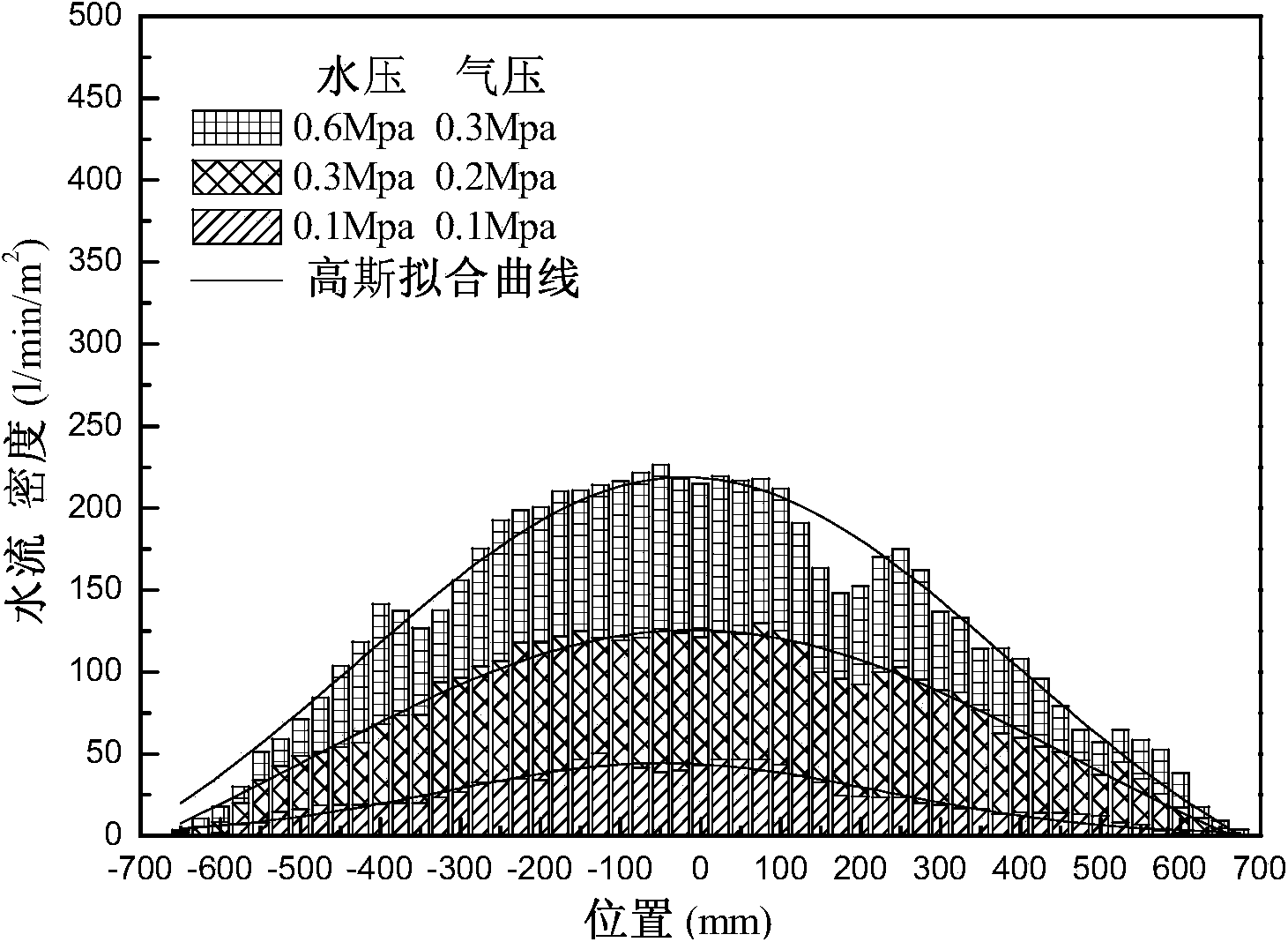

[0046] A two-dimensional solidification heat transfer calculation model is established. The heat transfer of the slab in the secondary cooling zone is mainly composed of radiation, roller contact heat transfer and secondary cooling convective heat transfer. The convective heat transfer coefficient of the secondary cooling water is The calculation method of can be expressed as:

[0047] h w i = α i · W i ( x ) 0.55 · ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com