Neutron density integrated instrument

A density and neutron technology, applied in the field of neutron density integrated instruments, can solve the problems of inability to guarantee the continuity and accuracy of data acquisition, increase program complexity, increase power consumption, etc., to reduce complexity, reduce settings, The effect of reducing the operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

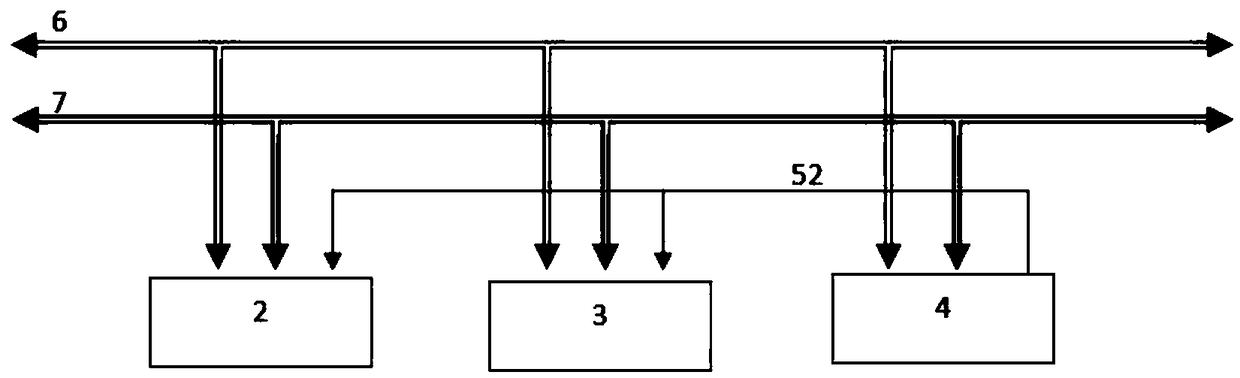

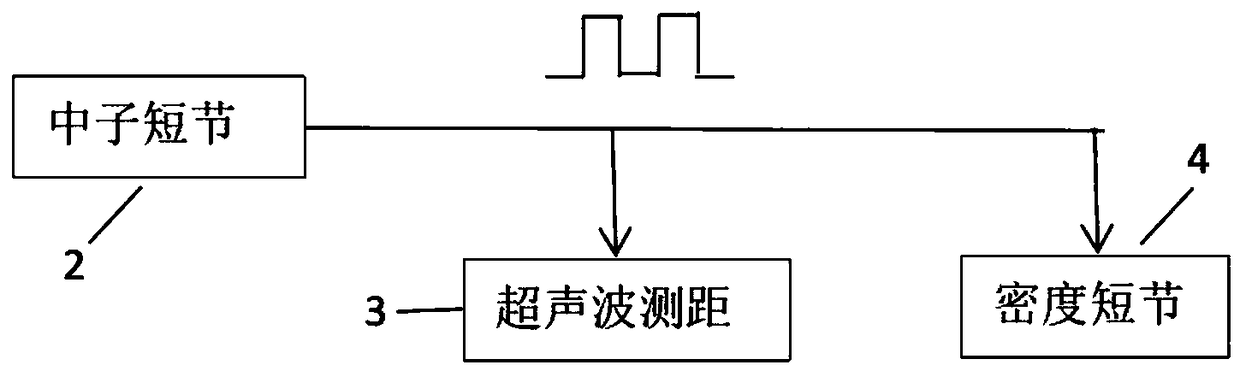

[0031] according to figure 1 , figure 2 As shown, the present invention discloses a neutron density integrated instrument, including a pressure-resistant tube 1, a neutron sub-section 2, an ultrasonic ranging sub-section 3, a density sub-section 4 and a synchronous pulse device 5, the neutron short Section 2, ultrasonic distance measuring short joint 3 and density short joint 4 are connected in sequence, and are set inside the pressure-resistant pipe 1; the synchronous pulse device 5 is set inside the density short joint; the neutron short joint 2 Including a neutron processor 21 for measuring formation porosity data; the ultrasonic distance measuring sub 3 includes an ultrasonic processor 31 for measuring the distance from the measuring instrument to the well wall; the density sub 4 includes a density processor 41. Acceleration sensor 42, the density processor 41 is used to measure formation density and photoelectric coefficient, and the acceleration sensor 42 is used to de...

Embodiment 2

[0035] according to figure 1 , figure 2 As shown, the present invention discloses a neutron density integrated instrument, including a pressure-resistant tube 1, a neutron sub-section 2, an ultrasonic ranging sub-section 3, a density sub-section 4 and a synchronous pulse device 5, the neutron short Section 2, ultrasonic distance measuring short joint 3 and density short joint 4 are connected in sequence, and are set inside the pressure-resistant pipe 1; the synchronous pulse device 5 is set inside the density short joint; the neutron short joint 2 Including a neutron processor 21 for measuring formation porosity data; the ultrasonic distance measuring sub 3 includes an ultrasonic processor 31 for measuring the distance from the measuring instrument to the well wall; the density sub 4 includes a density processor 41. Acceleration sensor 42, the density processor 41 is used to measure formation density and photoelectric coefficient, and the acceleration sensor 42 is used to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com