Narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials

A technology of laser scanning and welding methods, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of difficult wire filling, unstable droplet transition, etc., and achieve stable and easy welding process, reducing Pore defects, the effect of reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

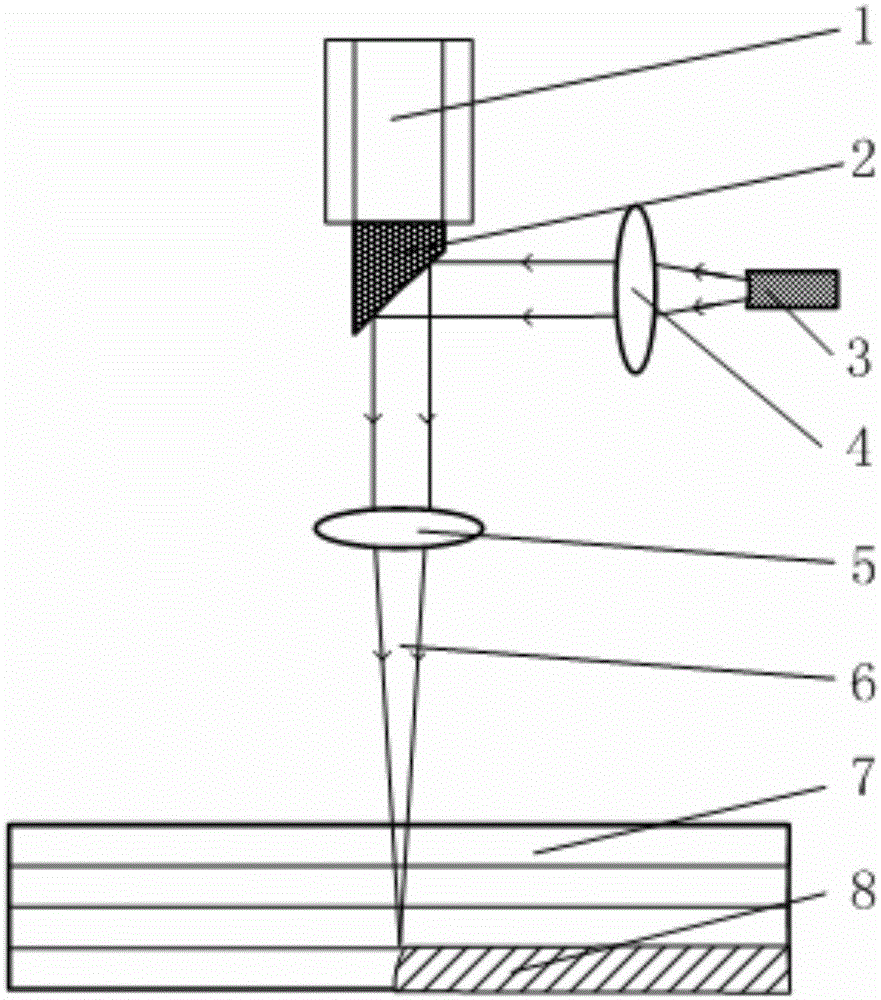

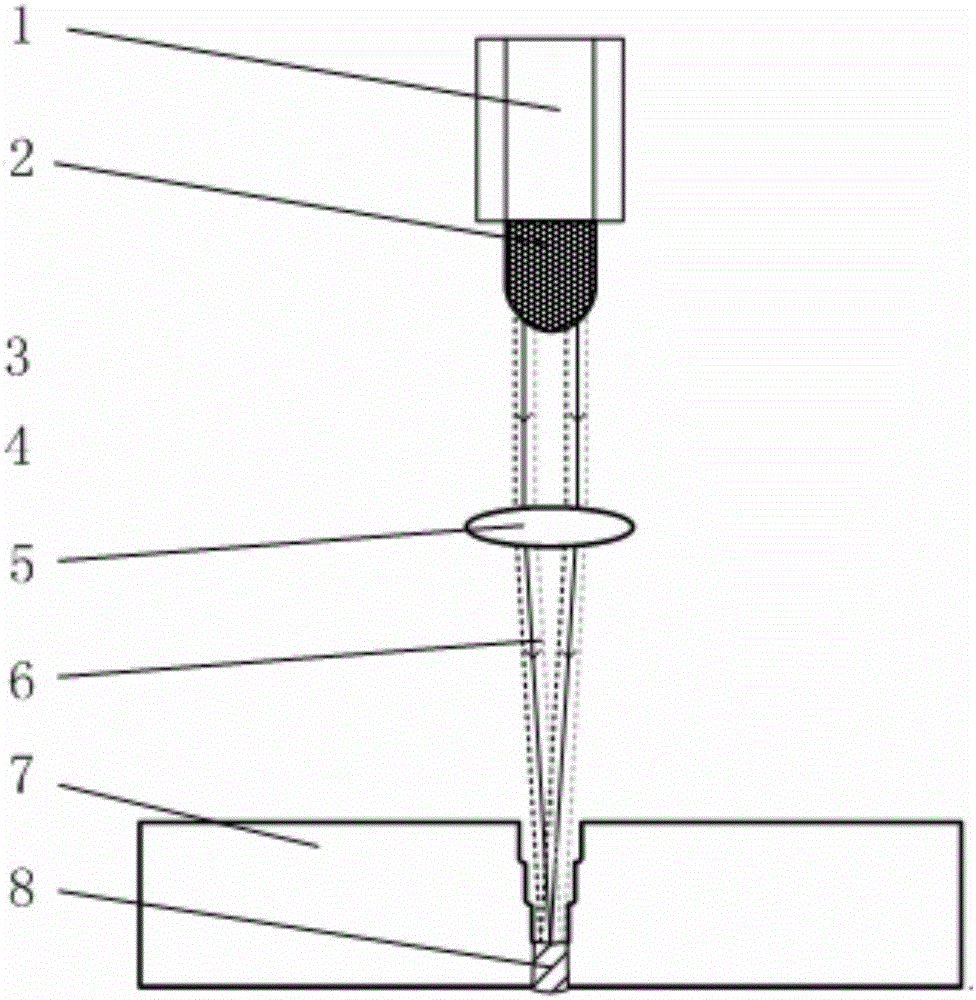

[0030] Specific implementation mode 1: The narrow gap laser scanning multilayer self-fusion welding method based on prefabricated welding material of this embodiment is carried out in the following steps:

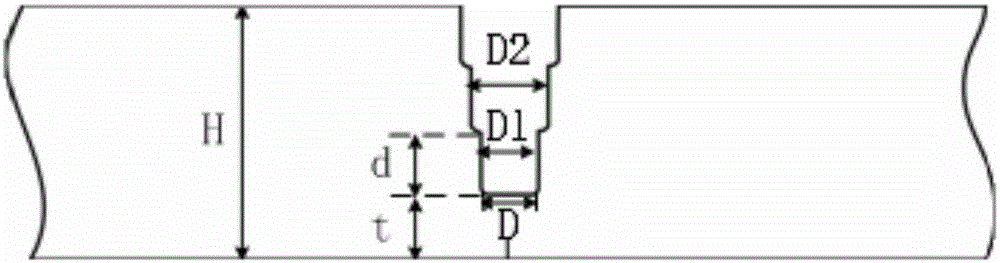

[0031] 1. Processing grooves: U-shaped grooves or V-shaped grooves with blunt edges are processed between two thick plates to be welded, the thickness of the blunt edges is t, and the U-shaped grooves or V-shaped grooves have multiple layers. For the prefabricated filling layer, the height d of the single prefabricated filling layer is controlled to be equal to the thickness t of the blunt edge. The width D of the U-shaped groove is distributed in steps, and D increases as the number of prefabricated filling layers increases, layer by layer Increase of groove width D between ΔD=D 2 -D 1 , Where D 1 Is the initial groove width, D 2 Is the second groove width, control ΔD to 0.5mm~2mm, control the initial groove width D 1 2mm~4mm; The width D of the V-shaped groove increases linea...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness t of the blunt edge described in step 1 is less than or equal to the maximum penetration depth of the laser beam single-layer scanning. The other steps and parameters are the same as in the first embodiment.

[0042] The thickness t of the blunt edge depends on the maximum output power of the laser used and the beam scanning speed.

specific Embodiment approach 3

[0043] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the thickness t of the blunt edge described in step one is 3 mm to 8 mm. The other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com