Oxygen-enriched air refining method for copper by using converting furnace

A blowing furnace and oxygen-enriched technology, which is applied in the process operation and control field under the oxygen-enriched condition of the Ausmelt blowing furnace, can solve the needs of large-scale industrial production, process safety problems, and difficulty in production capacity, etc. problems, to achieve the effect of improving production conditions, environmental protection conditions, and increasing blister copper production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

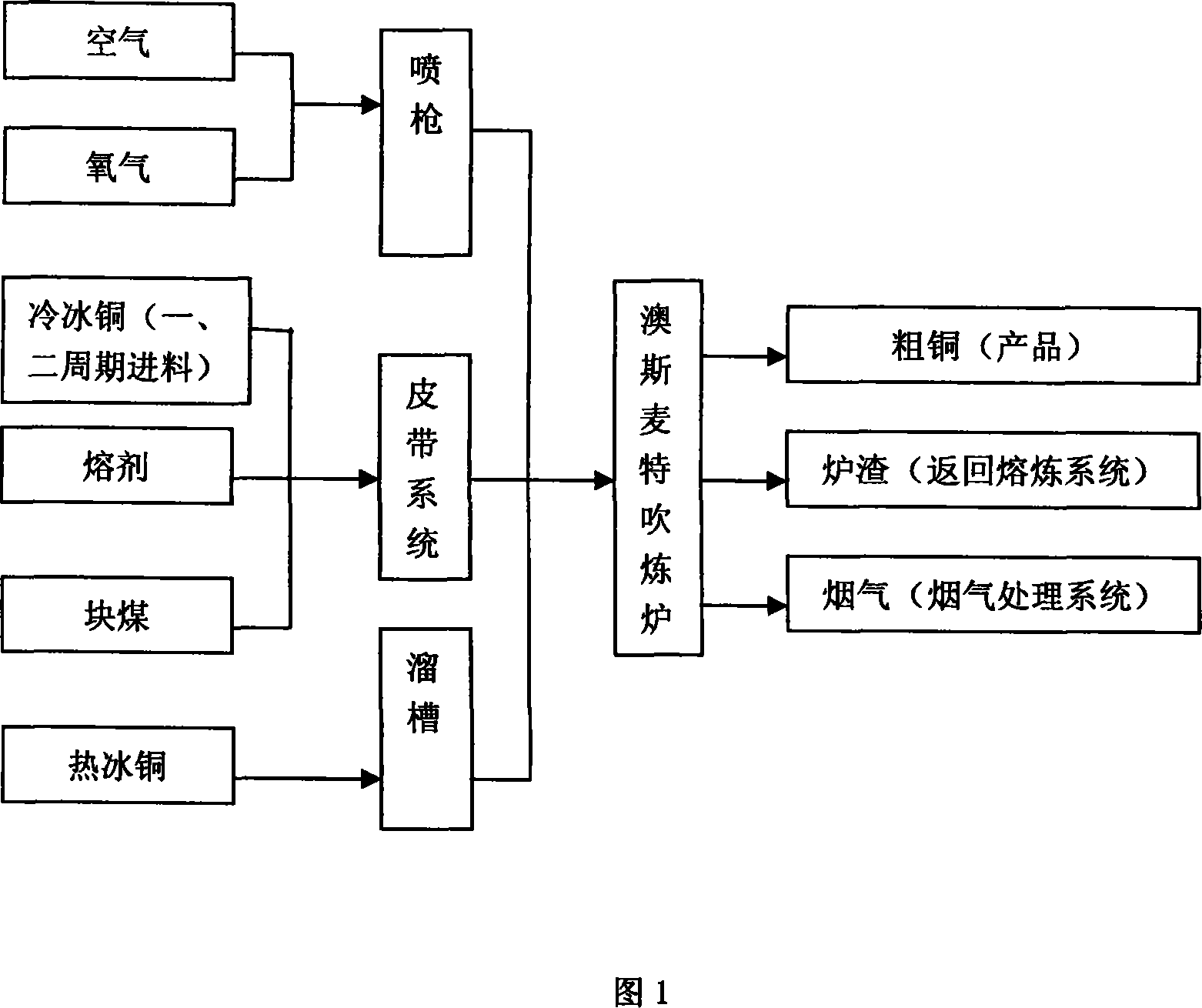

[0029] Describe in detail below in conjunction with accompanying drawing of the present invention:

[0030] The principle of oxygen-enriched copper blowing in a blowing furnace of the present invention is: it is equivalent to air blowing, the air blown into the high-temperature melt through the spray gun and the matte in the furnace undergo an oxidation reaction, and the sulfur and oxygen in the matte The sulfur dioxide generated by the reaction enters the flue gas treatment system, the iron in the matte is oxidized and slags with the flux, the copper is purified, and finally produces blister copper with a grade of more than 98.6%. Oxygen-enriched blowing makes the oxidation reaction of sulfur and iron more intense due to the increase of oxygen concentration, but at the same time brings a more serious risk of slag foaming.

[0031] As shown in Fig. 1, the process flow diagram of a method for blowing copper with oxygen enrichment in a blowing furnace according to the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com