Full-automatic bubble pressing machine

A fully automatic, bubble-pressing mechanism technology, applied in container manufacturing machinery, decorative art, paper/cardboard containers, etc., can solve problems such as difficult assembly line production, large machine shape, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

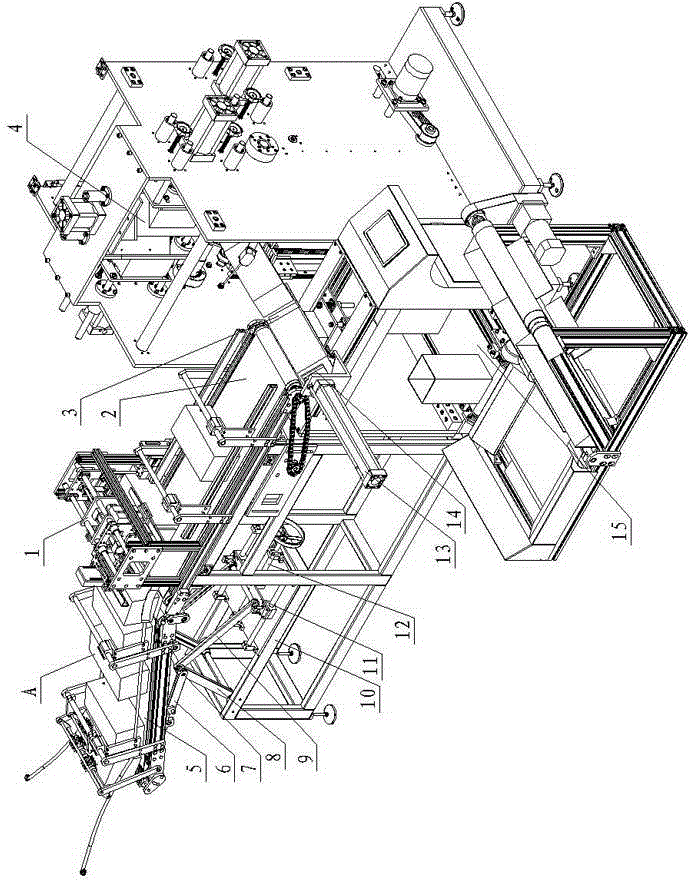

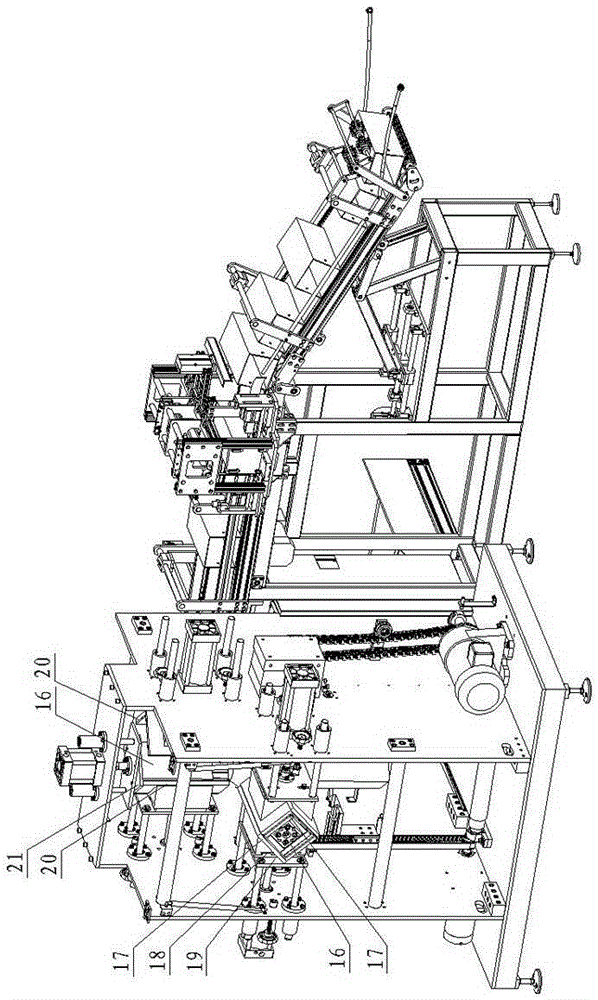

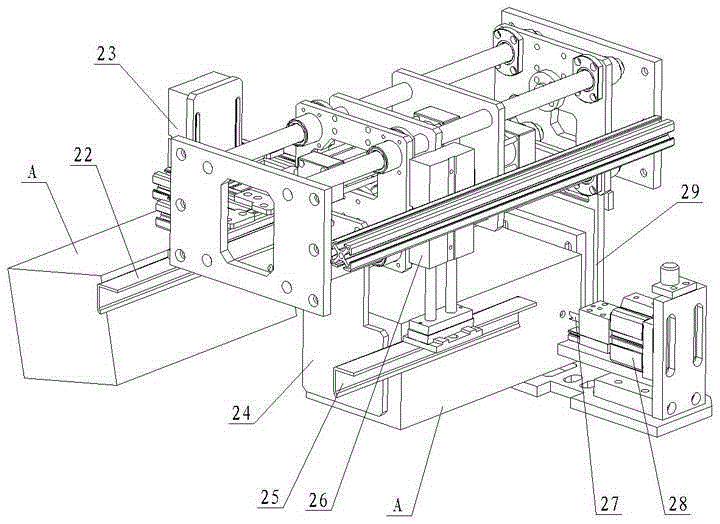

[0019] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0020] As shown in the figure, the fully automatic bubble making machine of the present invention includes a box feeding mechanism 2 and a bubble pressing mechanism 4, and the bubble pressing mechanism 4 includes a vertical turntable 38, which is connected with an indexing device for indexing rotation, vertically The upper circumference of the rotary table 38 is evenly distributed with four foam-pressing bottom molds 16 corresponding to the box feeding station, the first foam pressing station, the second foam pressing station and the box-out station, and the box feeding station is located on the vertical turntable 38 In front of the box station, the wine box positioning block 3 is aligned with the bubble bottom mold 16. The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com