Preparation method and application of silver iodide/bismuth oxybromide heterojunction photocatalyst

A photocatalyst and heterojunction technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high excitation energy, low photocatalytic activity, anesthesia, etc., and achieve saving The effect of synthesis cost, cheap and easy-to-obtain raw materials, and effective control of morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

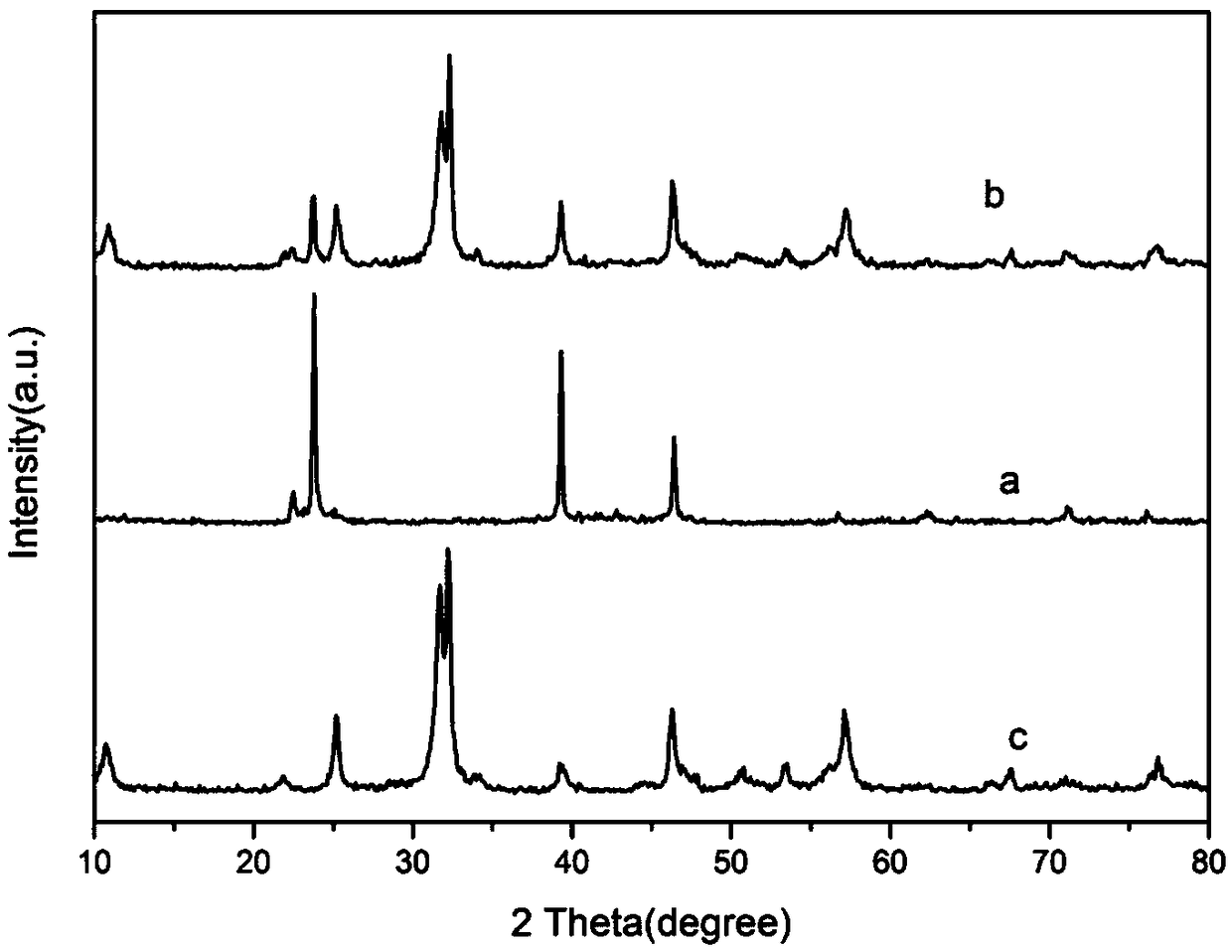

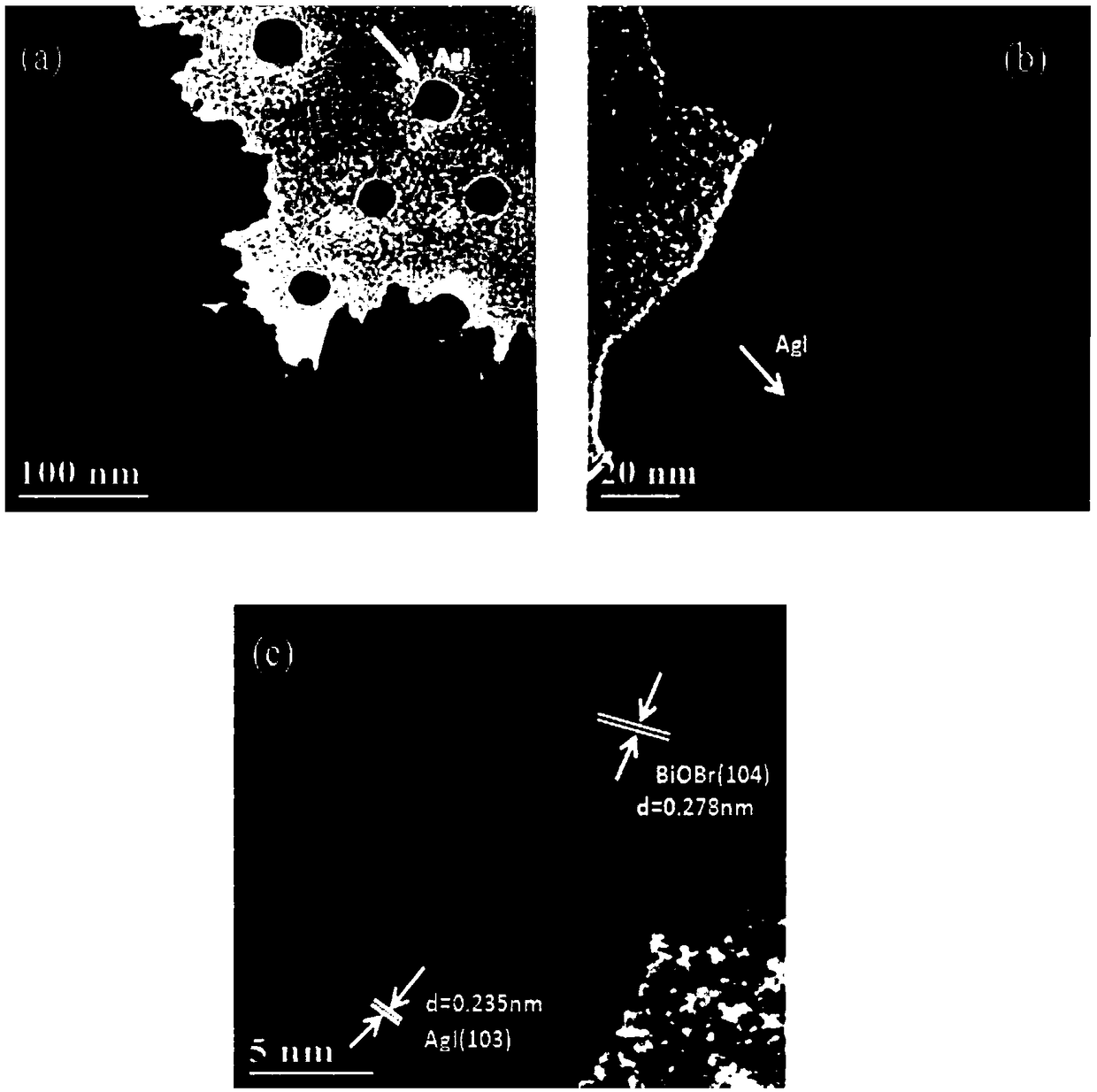

Method used

Image

Examples

Embodiment 1

[0048] (1) Dissolve 2 mmol of bismuth salt in 30 ml of ethylene glycol and stir magnetically for 30 min at room temperature;

[0049] (2) Dissolve 2 mmol of bromine source in 30 ml of ethylene glycol, stir magnetically at room temperature for 10 min, add dropwise to the above solution, and continue stirring for 1 h;

[0050] (3) Transfer the above mixed solution to a reaction kettle, put it in an oven at 145°C for 18 h, and obtain a milky white solid;

[0051] (4) The milky white solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0052] (5) Take out the dried solid and grind it with an agate mortar to obtain dry BiOBr powder;

[0053] (6) Dissolve 2 mmol of silver salt in 40 ml of deionized water and stir at room temperature for 15 min;

[0054] (7) Add the prepared BiOBr powder into the above solution and continue stirring for 15 min;

[0055] (8) Add 2 mmol iodine source dropwis...

Embodiment 2

[0059] (1) Dissolve 2 mmol of bismuth salt in 30 ml of ethylene glycol and stir magnetically for 30 min at room temperature;

[0060] (2) Dissolve 2 mmol of bromine source in 30 ml of ethylene glycol, stir magnetically at room temperature for 10 min, add dropwise to the above solution, and continue stirring for 1 h;

[0061] (3) Transfer the above mixed solution to a reaction kettle, put it in an oven at 125°C for 18 h, and obtain a milky white solid;

[0062] (4) The milky white solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0063] (5) Take out the dried solid and grind it with an agate mortar to obtain dry BiOBr powder;

[0064] (6) Dissolve 2 mmol of silver salt in 40 ml of deionized water and stir at room temperature for 15 min;

[0065] (7) Add the prepared BiOBr powder into the above solution and continue stirring for 15 min;

[0066] (8) Add 2 mmol iodine source dropwis...

Embodiment 3

[0070] (1) Dissolve 2 mmol of bismuth salt in 30 ml of ethylene glycol and stir magnetically for 30 min at room temperature;

[0071] (2) Dissolve 2 mmol of bromine source in 30 ml of ethylene glycol, stir magnetically at room temperature for 10 min, add dropwise to the above solution, and continue stirring for 1 h;

[0072] (3) Transfer the above mixed solution to a reaction kettle, put it in an oven at 165°C and react for 18 hours to obtain a milky white solid;

[0073] (4) The milky white solid was separated by centrifugation, washed three times with deionized water and absolute ethanol respectively, and dried in an oven at 60°C;

[0074] (5) Take out the dried solid and grind it with an agate mortar to obtain dry BiOBr powder;

[0075] (6) Dissolve 2 mmol of silver salt in 40 ml of deionized water and stir at room temperature for 15 min;

[0076] (7) Add the prepared BiOBr powder into the above solution and continue stirring for 15 min;

[0077] (8) Add 2 mmol iodine so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com