Method for preparing terbium oxide assembled carbon nano tube composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of new composite materials of carbon nanotubes assembled with terbium trioxide, can solve the problems of low coating rate and filling rate, affecting material properties, etc., and the method is simple and good Catalytic, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 3.2g terbium heptoxide in concentrated nitric acid, remove excess nitric acid by heating, and evaporate to dryness to prepare terbium nitrate crystals. At room temperature, terbium nitrate crystals and 40ml concentrated nitric acid are stirred and mixed at a speed of 400 rpm, and then Add 1g of carbon nanotubes, ultrasonically disperse, and reflux in an oil bath at 120°C for 6 hours. When the temperature of the refluxed mixture drops to room temperature, titrate with 15mol / L ammonia water until the pH is 8, and the titrated solution Filtrate with a filter membrane with a filter hole diameter of 0.65 μm, wash the filtrate with deionized water several times, and dry it in an oven at 80 ° C for 10 hours. After the filtrate is dried, carbon nanotubes assembled with terbium hydroxide are obtained. Put it into a quartz boat, put it into a tube-type atmosphere furnace, feed nitrogen, the gas flow rate is 1 liter / min, the heating rate is 5°C / min, from room temperature t...

Embodiment 2

[0034] Dissolve 4.0g terbium heptoxide in concentrated nitric acid, heat to remove excess nitric acid, and evaporate to dryness to prepare terbium nitrate crystals. At room temperature, terbium nitrate crystals and 40ml concentrated nitric acid are stirred and mixed at a speed of 600 rpm, and then Add 0.5g of carbon nanotubes, ultrasonically disperse, and reflux in an oil bath at 140°C for 3 hours. When the temperature of the refluxed mixture drops to room temperature, titrate with 30mol / L ammonia water until the pH is 9, and the titrated The solution was filtered with a filter membrane of 1.25 μm, and the filtrate was washed with deionized water several times, and then dried in an oven at 80°C for 12 hours. After the filtrate was dried, carbon nanotubes assembled with terbium hydroxide were obtained, which were placed in a quartz boat In a tube-type atmosphere furnace, argon gas is introduced, the gas flow rate is 2 liters / min, and the heating rate is 10°C / min. -1 The tempera...

Embodiment 3

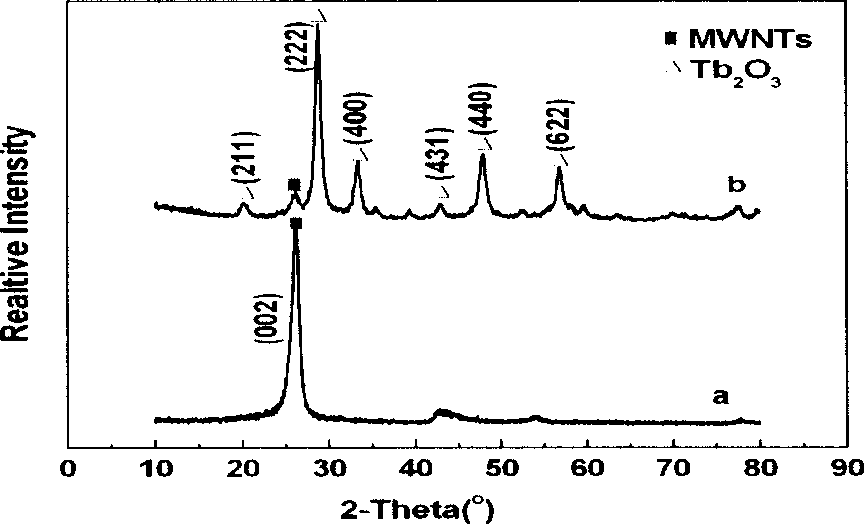

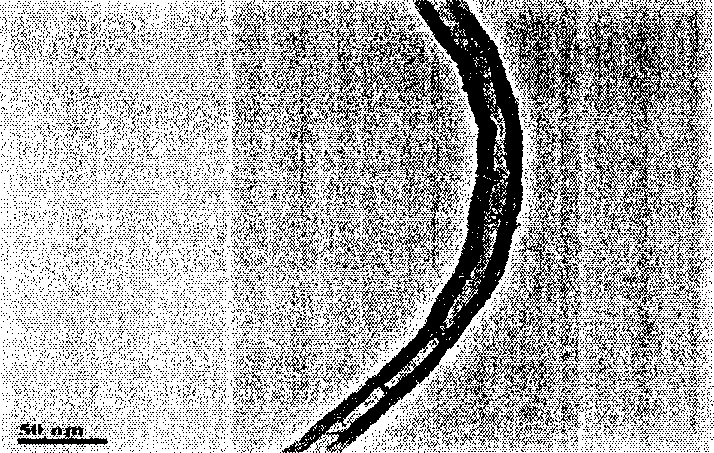

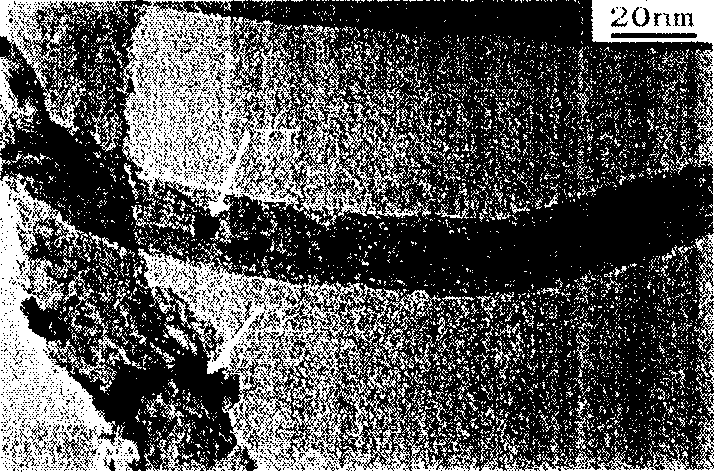

[0036]Dissolve 3.2g terbium heptoxide in concentrated nitric acid, heat to remove excess nitric acid, and evaporate to dryness to prepare terbium nitrate crystals. At room temperature, terbium nitrate crystals and 40ml concentrated nitric acid are stirred and mixed at a speed of 800 rpm, and then Add 0.5 g of carbon nanotubes, ultrasonically disperse, and reflux in an oil bath at 120° C. for 8 hours. When the temperature of the refluxed mixture drops to room temperature, titrate with 70 mol / L ammonia water, and prepare as described in Example 1 below . X-ray diffraction and transmission electron microscope analysis showed that terbium trioxide assembled carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com