Cu-La2O3/Al2O3 composite material and its preparing method

A composite material, al2o3 technology, applied in the field of metal matrix composite materials, can solve the problems of easy segregation, expensive equipment, particle reinforcement shape, distribution law and size cannot complement each other, to reduce segregation, less equipment investment, volume The effect that the score can control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

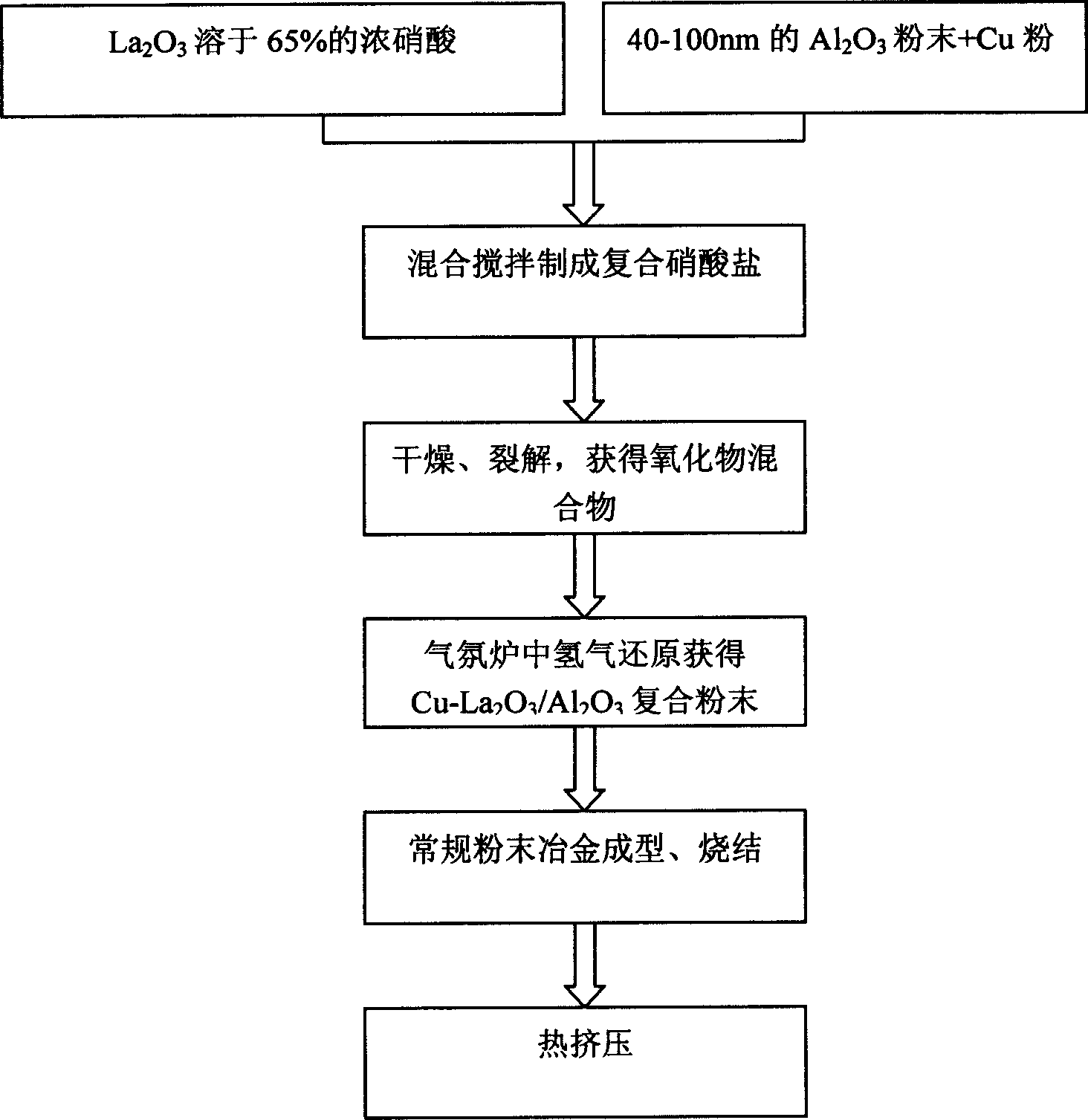

Method used

Image

Examples

Embodiment 1

[0035] Take 1g of La by weight as 1% 2 O 3 Dissolve in 30ml of 65% concentrated nitric acid, and then add 3g of 3% Al by weight after complete dissolution 2 O 3 , Al 2 O 3 The particle size is 40 ~ 100nm, fully stir and let stand for 1 hour;

[0036] Add distilled water according to the ratio of diluting the concentration of nitric acid to 20%, then add 96 g of copper powder accounting for 96% of the composite material mass, stir well and let stand for 2 hours, until the copper is completely converted into copper nitrate;

[0037] The above nitrate solution was placed in a box-type resistance furnace and dried at 400°C for 3 hours, then heated to 900°C for 3 hours, so that lanthanum nitrate and copper nitrate were respectively cracked into lanthanum oxide and copper oxide;

[0038] The cracked mixed oxide powder was placed in an atmosphere protection furnace, exhausted for 50 minutes, and after the hydrogen could be safely ignited, the temperature was raised to 400 °C at ...

Embodiment 2

[0041] Take 0.2g of La with a weight percentage of 0.2% 2 O 3 Dissolve in 30ml of 65% concentrated nitric acid, and then add 0.6g of 0.6% Al by weight after complete dissolution 2 O 3 , Al 2 O 3 The particle size is 40 ~ 100nm, fully stir and let stand for 0.5 hours;

[0042] Add distilled water according to the ratio of diluting the concentration of nitric acid to 30%, then add 99.2g of copper powder accounting for 99.2% of the composite material mass, fully stir and let stand for 1 hour, until the copper is completely converted into copper nitrate;

[0043] The above nitrate solution was placed in a box-type resistance furnace and dried at 300°C for 1 hour, then heated to 800°C for 3 hours, so that lanthanum nitrate and copper nitrate were respectively cracked into lanthanum oxide and copper oxide;

[0044] The cracked mixed oxide powder was placed in an atmosphere protection furnace, exhausted for 50 minutes, and after the hydrogen could be safely ignited, the temperat...

Embodiment 3

[0047] Take 0.5g of La with a weight percentage of 0.5% 2 O 3 Dissolve in 25ml of 65% concentrated nitric acid, and add 1.5g of 1.5% Al by weight after complete dissolution 2 O 3 , Al 2 O 3 The particle size is 40 ~ 100nm, fully stir and let stand for 1 hour;

[0048] Add distilled water according to the ratio of diluting the concentration of nitric acid to 25%, then add 98 g of copper powder which accounts for 98% of the composite material mass, fully stir and let stand for 1.5 hours, until the copper is completely converted into copper nitrate;

[0049] The above nitrate solution was placed in a box-type resistance furnace and dried at 400°C for 1 hour, then heated to 850°C and kept for 5 hours, so that lanthanum nitrate and copper nitrate were cracked into lanthanum oxide and copper oxide respectively;

[0050] The cracked mixed oxide powder was placed in an atmosphere protection furnace, exhausted for 50 minutes, and after the hydrogen could be safely ignited, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com