Process for preparing 2-methyl-1,4-naphthaquinoue using 2-methyl-naphthalene

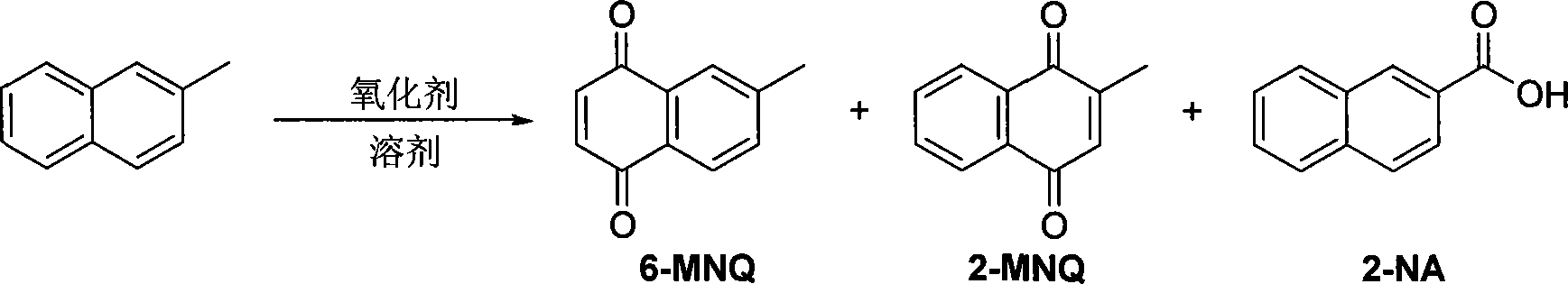

A technology of methyl naphthalene and methyl naphthylamine, applied in the field of preparing 2-methyl-1, can solve the problems of difficult recovery, high catalyst input cost, equipment corrosion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

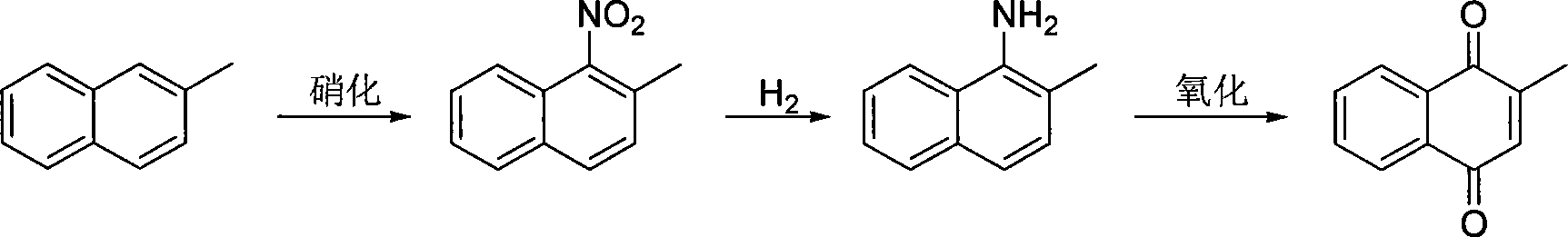

Method used

Image

Examples

Embodiment 1

[0020] 71g (0.5mol) of 2-methylnaphthalene was dissolved in 200ml of glacial acetic acid, cooled in an ice-water bath, and 50ml of fuming nitric acid was slowly added dropwise, and the dropwise addition was completed in about half an hour. Stir at 5-10° C. for 2 h, and track by TLC until the reaction is complete. Dilute with 750ml of water, extract with 100ml×3 dichloromethane, combine the organic phases, wash with saturated aqueous sodium bicarbonate until neutral, and dry over anhydrous magnesium sulfate. Filter, remove the solvent, and recrystallize with methanol to obtain 70-75 g of 2-methyl-1-nitronaphthalene, yield: 75-80%. mp.80~82℃; 1 HNMR (400MHz, CDCl 3 ): δ2.52(s, 3H), 7.35-7.38(m, 1H), 7.54-7.58(m, 1H), 7.62-7.67(m, 1H), 7.73-7.77(m, 1H), 7.88-7.90 (m,2H)ppm.

Embodiment 2

[0022] Dissolve 36g (0.25mol) of 2-methylnaphthalene in 200ml of dichloroethane, cool in an ice-water bath, add 1ml of concentrated sulfuric acid dropwise, then slowly add 30ml of concentrated nitric acid (content 65% to 68%) dropwise, and the dropwise addition is completed in about 30 minutes . Stir at 5-10° C. for 5 h, and track by TLC until the reaction is complete. Wash with 100 ml of water and 100 ml of saturated aqueous sodium bicarbonate, and dry over anhydrous magnesium sulfate. Filter and remove the solvent to obtain the crude product. After methanol recrystallization, the purity is 99% (HPLC), and the yield is 70-75%.

Embodiment 3

[0024] 48g (0.25mol) of 2-methyl-1-nitronaphthalene was dissolved in 20ml of ethyl acetate, 0.5g of 10% Pd / C catalyst was added, and stirred at room temperature under H2 atmosphere for 3 days. The catalyst was removed by filtration, and the filter cake was washed with a little ethyl acetate. The filtrate was dried over anhydrous magnesium sulfate, and the solvent was removed to obtain 40 g of an oily liquid product, 2-methylnaphthylamine, with a purity of 98% (HPLC), and a yield of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com