Synthesizing method of butyrolactone derivative

A synthesis method and derivative technology, applied in the field of synthesis of butyrolactone derivatives, can solve problems such as difficulty in maintaining extremely high chiral purity, and achieve the effects of good regioselectivity, simple steps, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

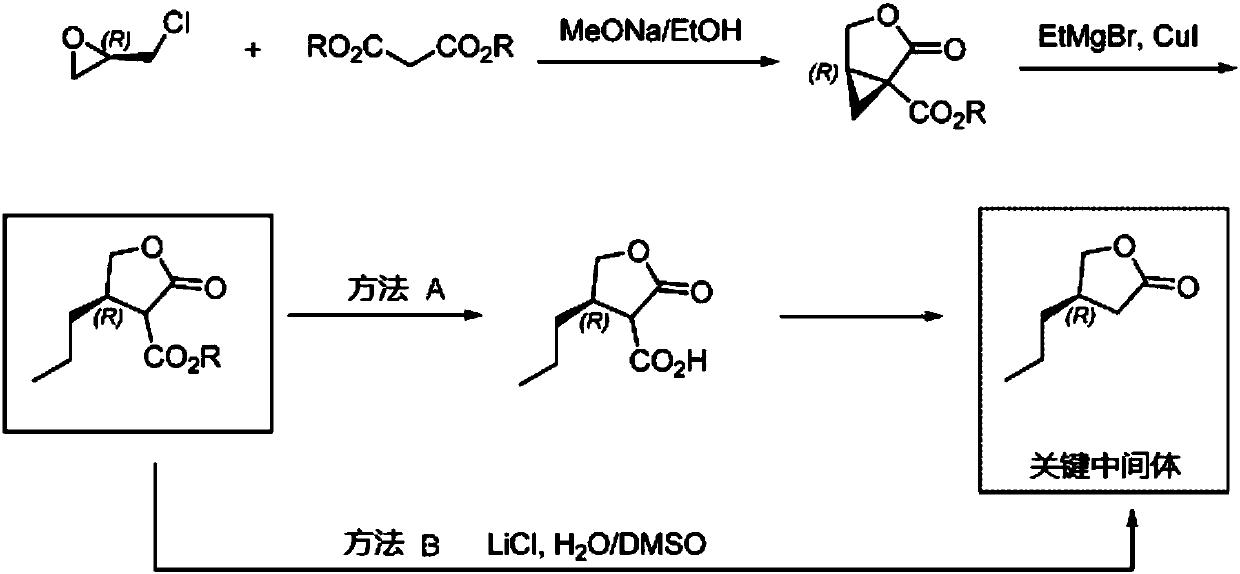

Method used

Image

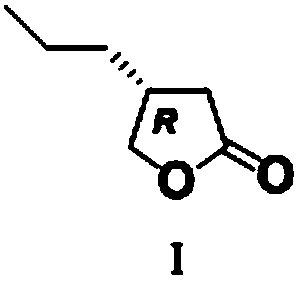

Examples

Embodiment 1

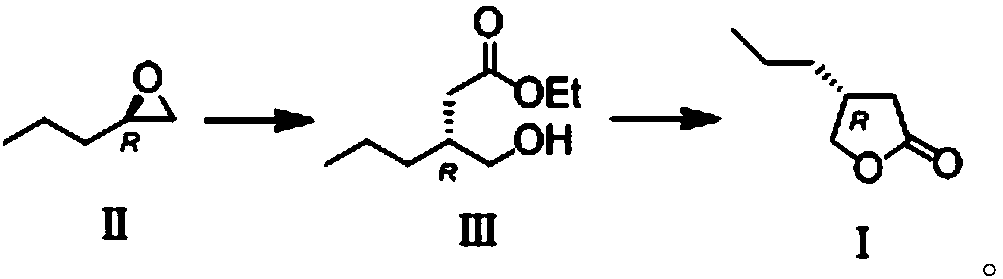

[0026] The preparation of (R)-2-propyl-oxirane shown in embodiment 1 formula (II)

[0027] The synthetic route is as follows:

[0028]

[0029] Add R-epichlorohydrin (4.0g, 43.2mmol), cuprous cyanide (387mg, 4.32mmol) and tetrahydrofuran (50mL) into the three-necked flask, cool to -78°C under stirring, and add 1mol / L ethyl bromide dropwise Magnesium chloride in tetrahydrofuran (21.6 mL, 64.9 mmol). The temperature of the reaction solution was slowly raised to -20°C, and 100 mL of saturated ammonium chloride aqueous solution was added dropwise. After the dropwise addition, the layers were allowed to stand and the water phase was extracted with methyl tert-butyl ether (50 mL×3). The organic phases were combined, dried over anhydrous magnesium sulfate, and concentrated to dryness under reduced pressure to obtain a yellow oil. The above yellow oil was dissolved in 50 mL of ether, powdered sodium hydroxide (9.4 g, 235 mmol) was added, vigorously stirred at room temperature for...

Embodiment 2

[0030] The preparation of embodiment 2 organozinc compounds

[0031] In a reaction flask, after zinc powder (15.1 g, 231 mmol) was mixed with 90 mL of toluene, trimethylchlorosilane (TMSCl) (3.7 mL, 29 mmol) was added under nitrogen protection, and the mixture was heated at 60° C. for 20 minutes, Then ethyl bromoacetate (213 mmol) was added dropwise, and the temperature was controlled at 60° C., heated at this temperature for 30 minutes, cooled to 20-30° C., and supernatant A was obtained after filtration, which was an organozinc compound.

Embodiment 3

[0032] The preparation of embodiment 3 organozinc compounds

[0033] In the reaction flask, after mixing zinc powder (174mmol) with 80mL toluene, trimethylchlorosilane (TMSCl) (3.7mL, 29mmol) was added under nitrogen protection, the mixture was heated at 50°C for 10 minutes, and then added dropwise Ethyl bromoacetate (145 mmol), and the temperature was controlled at 50°C, heated at this temperature for 20 minutes, cooled to 20-30°C, filtered to obtain the supernatant A, which was the organozinc compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com