Method for recycling waste silicon solution

A technology of silicon liquid and silicon powder, applied in the direction of silicon, etc., can solve problems such as waste of social resources and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

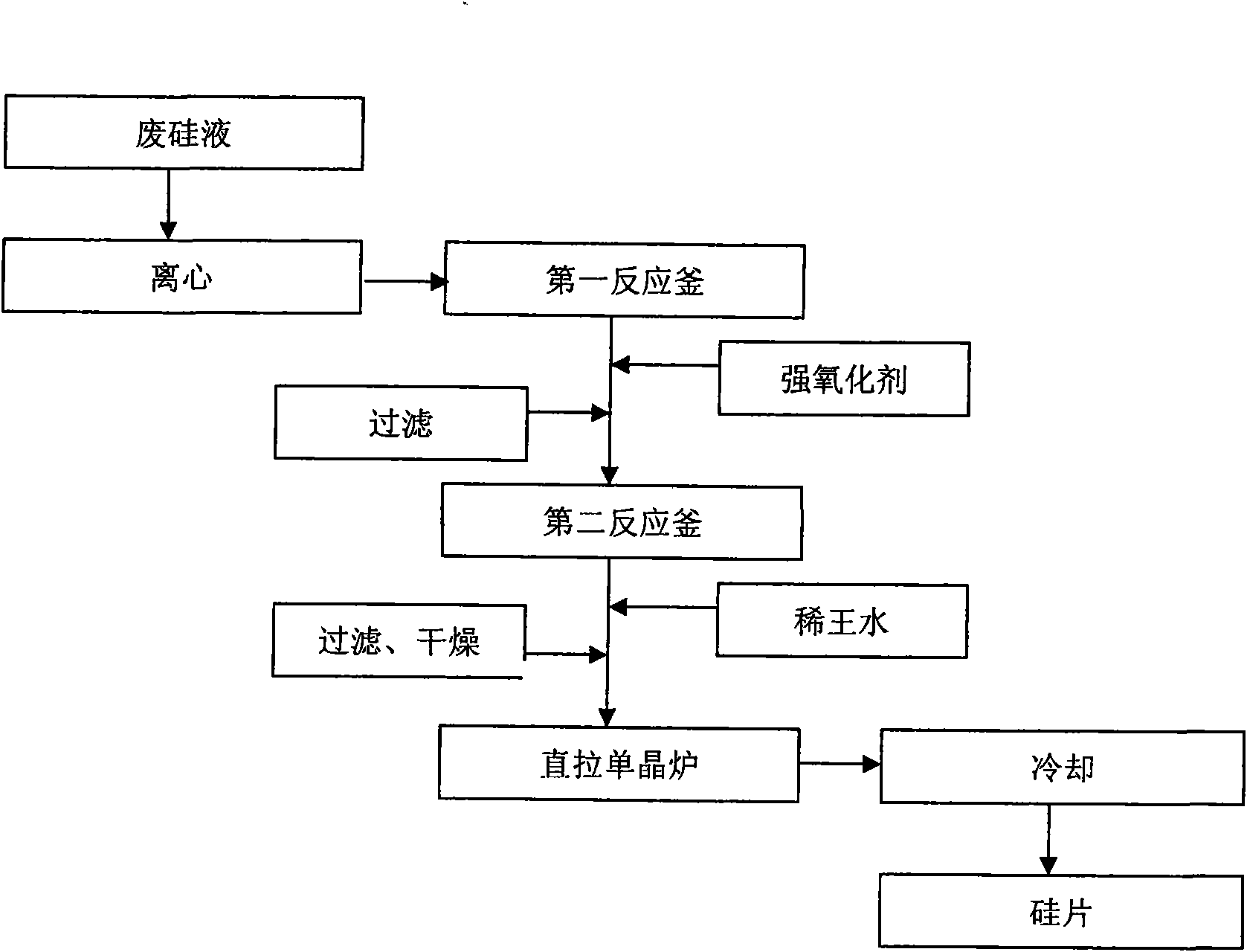

[0022] A method for recovering and regenerating waste silicon liquid, characterized in that the method comprises the following steps:

[0023] a. The waste silicon liquid produced by cutting silicon rods is centrifuged, and the filter cloth has a pore size of 800 mesh to obtain silicon powder;

[0024] b. Place the separated silicon powder in a reaction kettle, add a strong oxidant to react, filter the reaction solution to remove organic carbon impurities, and the strong oxidant is a mixture of hydrogen peroxide and concentrated sulfuric acid with a ratio of 10:1;

[0025] c, place the silicon powder material obtained by secondary filtration in the reaction kettle, add dilute aqua regia to react, and the reaction solution is filtered and dried to remove metal and metal oxide impurities. The proportioning of hydrochloric acid, nitric acid and water in dilute aqua regia is 1:1:10;

[0026] d. Put the silicon powder obtained by filtering three times in a Czochralski single cryst...

Embodiment 2

[0028] Repeat the same steps as described in Example 1, but wherein the filter cloth aperture is 1500 mesh, the strong oxidant is a mixture of hydrogen peroxide and concentrated sulfuric acid with a ratio of 1:10, and the ratio of hydrochloric acid, nitric acid and water in dilute aqua regia is: 1:5:10, the temperature of the single crystal furnace is 1000°C.

Embodiment 3

[0030] Repeat the same steps as described in Example 1, but wherein the filter cloth aperture is 1000 mesh, the strong oxidant is a mixture of hydrogen peroxide and concentrated sulfuric acid with a ratio of 5:6, and the ratio of hydrochloric acid, nitric acid and water in dilute aqua regia is: 1:4:8, the temperature of the single crystal furnace is 900°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| charge carrier lifetime | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com