Method for continuously dilution diluting aqua fortis and controlling generation of NO2

A concentrated nitric acid, NO2 technology, applied in the direction of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of complex dilution equipment, large pollution, low efficiency, etc., to avoid the decomposition of nitric acid and reduce the temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

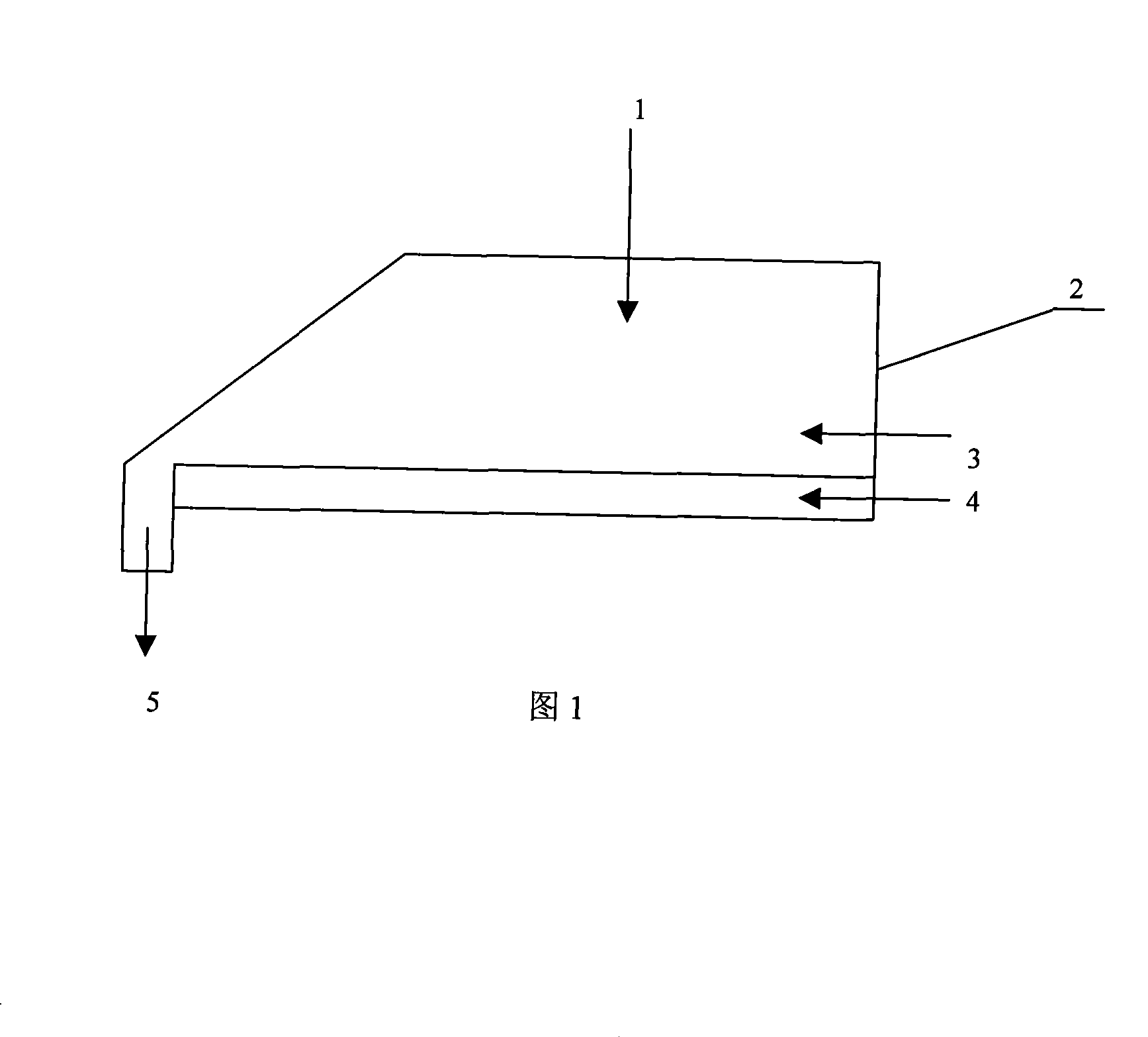

[0012] As shown in Figure 1, the stainless steel pipe is connected to the concentrated nitric acid storage tank through a flow meter and a power pump, and the concentrated nitric acid 3 is transported to the high end on the right side of the flat-bottomed tank 2 by the pump according to the required flow rate, so that it flows to the left. Concentration and quantity, the spray water 1 is continuously sprayed to the surface of the flowing concentrated nitric acid 3 through the distributor, the two are mixed during the flow, and flow to the low-end dilute nitric acid container 5. During this period, the cooling medium 4 can be passed through the interlayer at the bottom of the flat-bottomed tank 2 to lower the temperature.

[0013] For example, taking 98% concentrated nitric acid as an example, at 20°C, the area of the stainless steel pipe for pumping concentrated nitric acid is 66cm 2 , the flow rate of concentrated nitric acid is 12.63cm / s, and the area of the flat-bottome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com