Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

An anhydrous calcium sulfate, calcium sulfate whisker technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc. Application, enhancement effect reduction and other problems, to achieve the effect of high product added value, easy industrial promotion, and regular appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

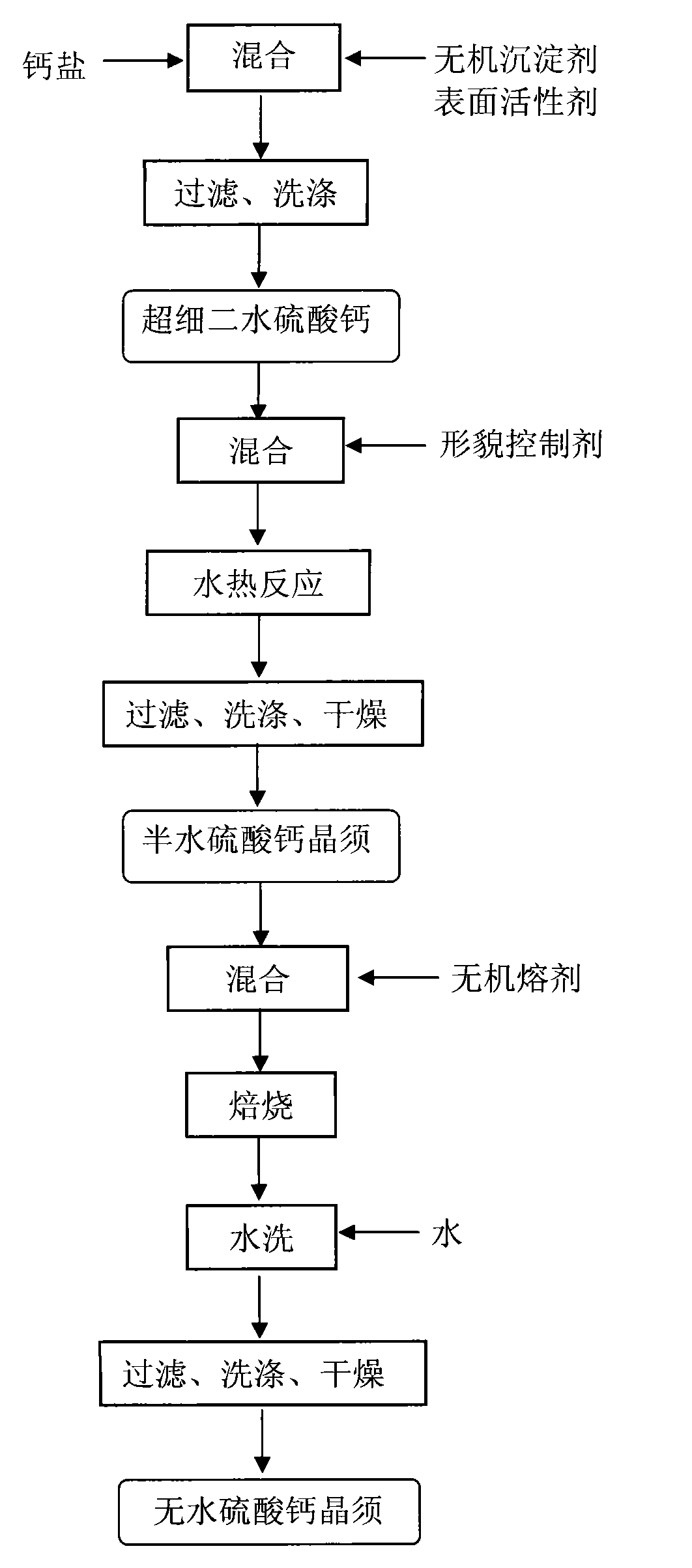

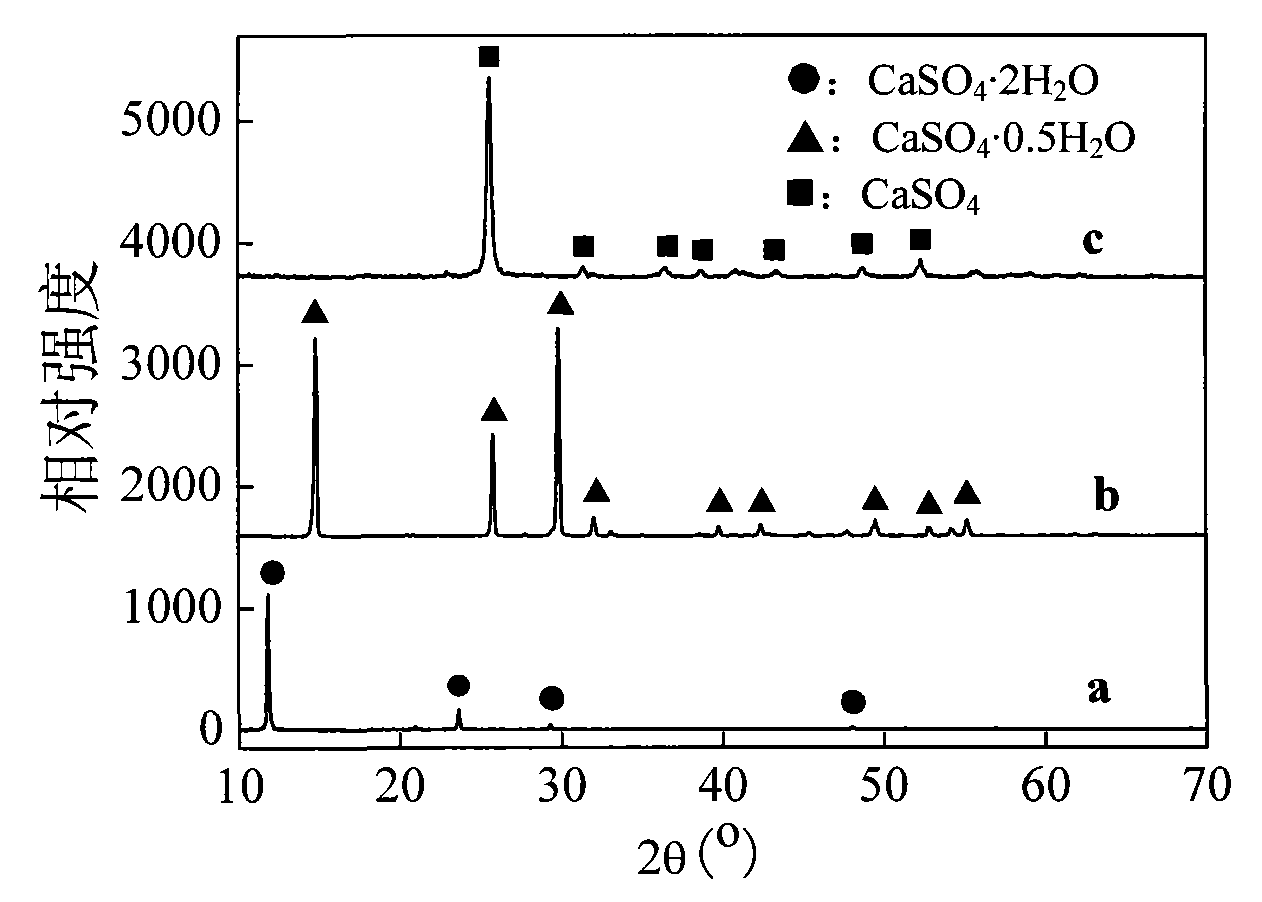

[0020] The invention provides a method for preparing calcium sulfate whiskers with high aspect ratio. Using inorganic calcium salts and inorganic precipitants as raw materials and surfactants as dispersants, first prepare well-dispersed ultrafine calcium sulfate dihydrate precursors at room temperature; then use the selection of morphology control agents under hydrothermal conditions The one-dimensional directional growth of calcium sulfate hemihydrate is promoted by the adsorption effect; then the shrinkage cavity elimination and structural reformation are realized by flux roasting method, thus obtaining sulfuric acid with large aspect ratio, uniform and regular shape, high crystallinity and good dispersion calcium whiskers. Specific steps are as follows:

[0021] 1) Using inorganic calcium salt and inorganic precipitant as raw materials, using surfactant as dispersant, under the condition that the temperature is 10-90°C and the stirring speed is 50-500 rpm, the inorganic pr...

Embodiment 1

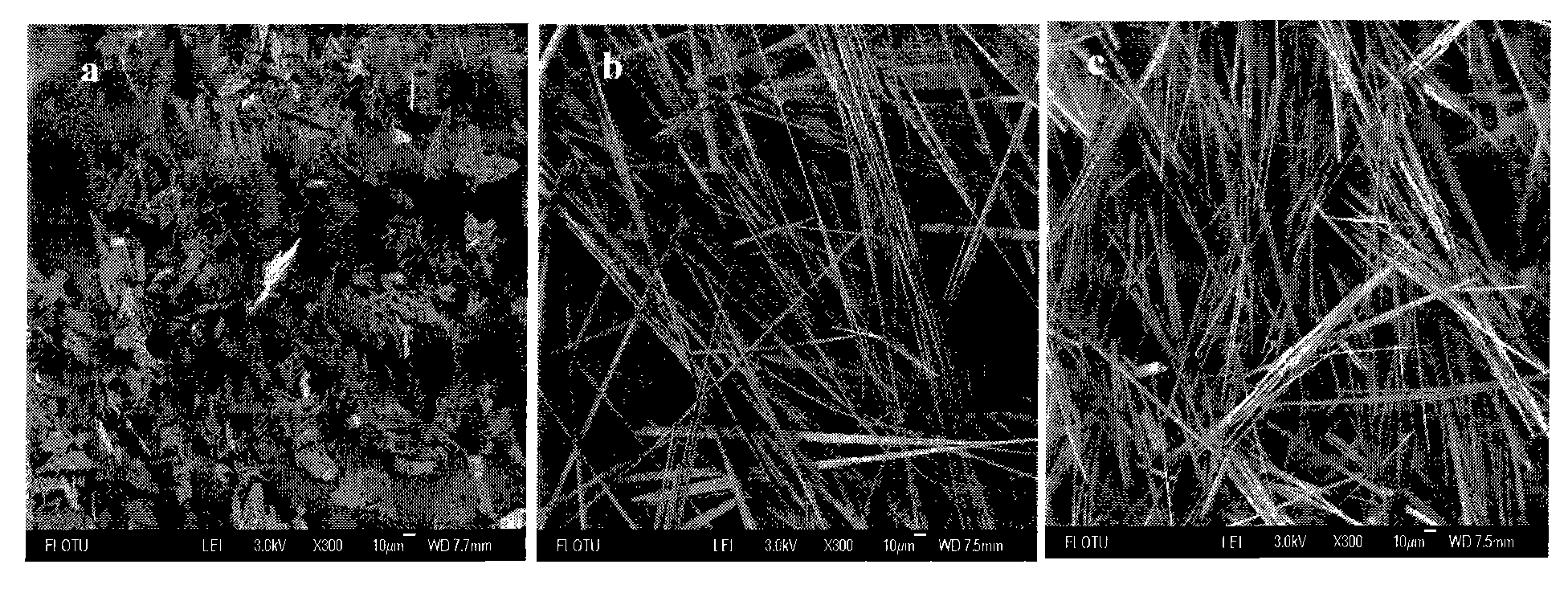

[0029] Prepare 100 mL of a mixed solution containing 0.1 mol / L calcium chloride and 0.001 mol / L cetyltrimethylammonium bromide, and 100 mL of a 0.1 mol / L sulfuric acid solution. Under the condition that the temperature is 10°C and the stirring speed is 50 rev / min, add the sulfuric acid solution into the mixed solution containing calcium chloride and cetyltrimethylammonium bromide at a speed of 20mL / min, and continue to React for 0.5 hours to obtain a white milky slurry; filter and wash the above-mentioned slurry and put it into a high-pressure reactor, add a sodium chloride solution with a molar concentration of 0.005mol / L, adjust the solid content to 0.1wt%, at a temperature of 100°C 1. Under the condition of stirring speed of 50 rev / min, the hydrothermal reaction was carried out for 10 hours, cooled, filtered, washed and dried (105° C., 4 hours) to obtain the intermediate product of calcium sulfate hemihydrate whiskers. Mix calcium sulfate hemihydrate whiskers with sodium ch...

Embodiment 2

[0031] Prepare 100 mL of a mixed solution containing 5 mol / L calcium nitrate and 0.5 mol / L sodium dodecylbenzenesulfonate, and 100 mL of a 5 mol / L potassium sulfate solution. At a temperature of 90°C and a stirring speed of 500 rpm, add the potassium sulfate solution to the mixed solution containing calcium nitrate and sodium dodecylbenzenesulfonate at a rate of 1 mL / min, and continue the reaction for 2 hours after the addition is complete. , to obtain a white milky slurry; the above-mentioned slurry is filtered and washed and put into an autoclave, adding a molar concentration of 5mol / L potassium chloride solution to adjust the solid content to 20wt%. Hydrothermal reaction under different conditions for 0.5 hours, cooling, filtering, washing, and drying (105°C, 4 hours) to obtain the intermediate product of calcium sulfate hemihydrate whiskers. Mix calcium sulfate hemihydrate whiskers with potassium chloride, control the weight ratio of the two to 100:10, place the mixture in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com