Rapid-molding powder material for three-dimensional printing as well as preparation method and application thereof

A powder material and three-dimensional printing technology, which is applied in the field of rapid prototyping powder materials and their preparation, can solve the problems of insufficient water resistance and strength, complex post-processing, and insufficient strength of devices, and achieve high density, wide source of raw materials, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

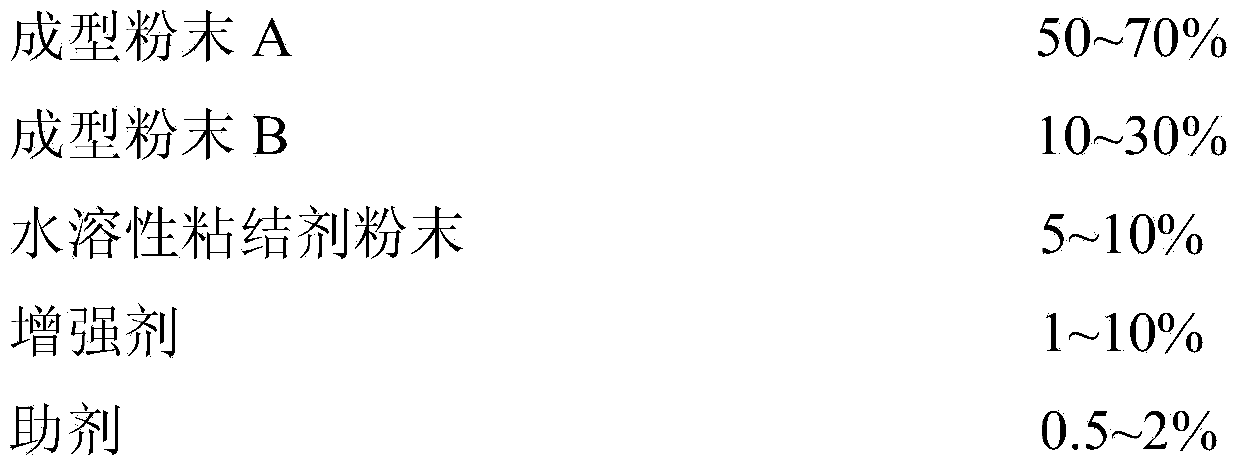

[0046] A composite powder for three-dimensional rapid prototyping, consisting of the following raw materials in mass percentage:

[0047]

[0048] During preparation, firstly mix α-type calcium sulfate hemihydrate gypsum powder (commercially available high-strength gypsum powder with whiteness of 92%, standard thickness of 42%, initial setting time of 2 to 3 minutes, and 2h flexural strength of 6.50MPa) And polyurethane powder (polyurethane powder TPU-70*20) was sieved into three parts with particle sizes ranging from 1 μm to 30 μm, 30 μm to 50 μm, and 50 μm to 70 μm, and the mass percentages of the three parts were respectively 5%, 70%, and 25% as The required α-type calcium sulfate hemihydrate gypsum powder and polyurethane powder in this embodiment.

[0049] The above-mentioned α-type calcium sulfate hemihydrate gypsum powder and polyurethane powder obtained above are added in the mixer and mixed for 20min, then polyvinyl alcohol (polyvinyl alcohol 1788 produced by Shang...

Embodiment 2

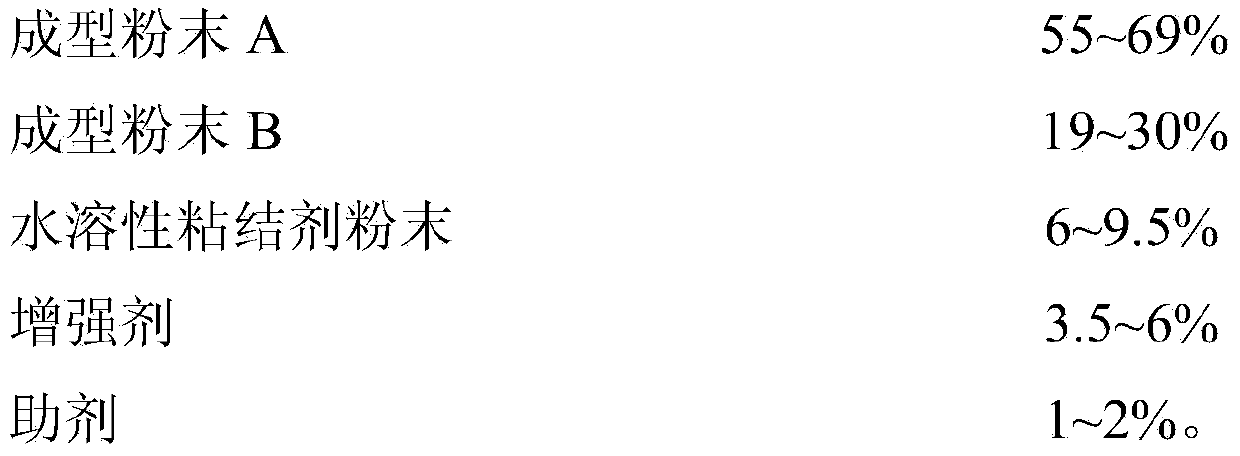

[0051] A composite powder for three-dimensional rapid prototyping, consisting of the following raw materials in mass percentage:

[0052]

[0053] During preparation, firstly mix α-type calcium sulfate hemihydrate gypsum powder (commercially available high-strength gypsum powder with whiteness of 92%, standard thickness of 28%, initial setting time of 6 to 8 minutes, and 2h flexural strength of 8.50MPa) And polyethylene wax micropowder (polyethylene wax micropowder PE) is sieved into particle size scope and is 1 μm~30 μm, 30 μm~50 μm, 50 μm~70 μm three parts, get three parts mass percent content and be respectively 8%, 65%, 27% as The required α-type calcium sulfate hemihydrate gypsum powder and polyethylene wax micropowder required by the present embodiment.

[0054] Add the above-mentioned α-type calcium sulfate hemihydrate gypsum powder and polyethylene wax micropowder into the grinder and mix for 10 minutes, then add water-soluble starch (water-soluble starch produced b...

Embodiment 3

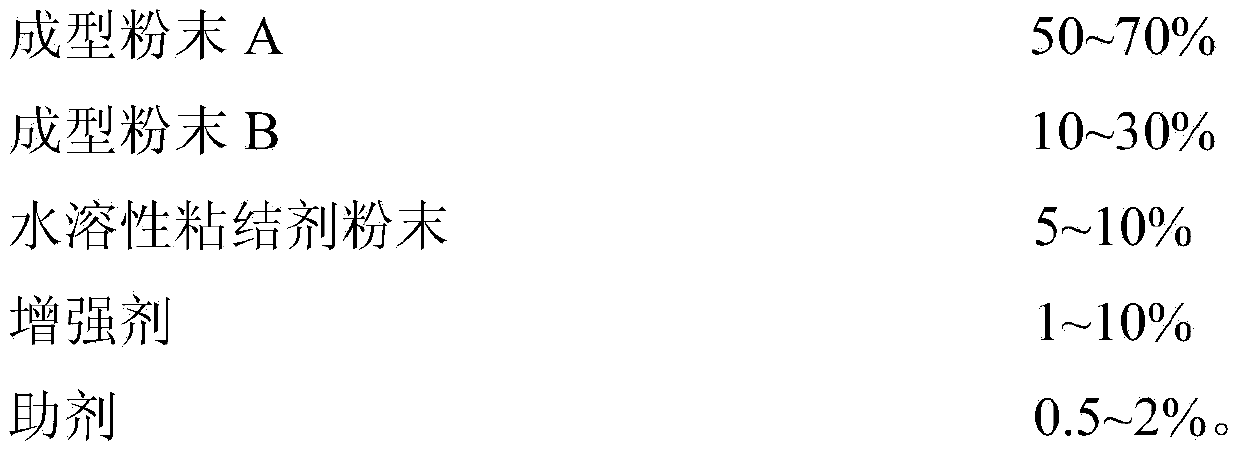

[0056] A composite powder for three-dimensional rapid prototyping, consisting of the following raw materials in mass percentage:

[0057]

[0058] During preparation, firstly mix α-type calcium sulfate hemihydrate gypsum powder (commercially available high-strength gypsum powder with whiteness of 92%, standard thickness of 28%, initial setting time of 6 to 8 minutes, and 2h flexural strength of 8.50MPa) And copolyamide hot-melt adhesive powder (copolyamide hot-melt adhesive powder PA-D180) is sieved into three parts with particle sizes ranging from 1 μm to 30 μm, 30 μm to 50 μm, and 50 μm to 70 μm, and the mass percentages of the three parts are respectively 5%, 60%, 35% are α-type calcium sulfate hemihydrate gypsum powder and copolyamide hot-melt adhesive powder required by the present embodiment.

[0059] After adding the above-mentioned α-type calcium sulfate hemihydrate gypsum powder and copolyamide hot-melt adhesive powder into the grinder and mixing for 30min, add pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com