Method for preparing calcium sulfate crystal whisker in low cost

A calcium sulfate whisker, low-cost technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., to achieve the effects of low production cost, improved performance, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

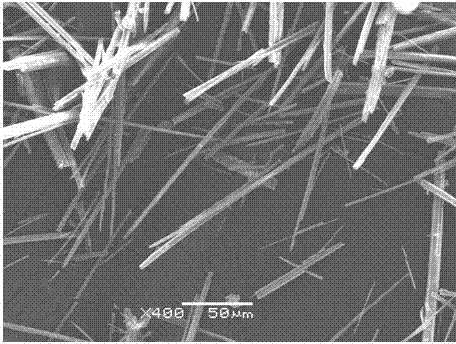

[0019] Take by weighing 50 kilograms of 200-300 purpose powdery heavy calcium carbonate, add in batches in the reaction kettle that 500 liters of 1mol / L dilute sulfuric acid solutions are housed, react under stirring until no gas escapes, add 11.2 kilograms of magnesium chloride and 300 Kg of water, stir evenly, pour into a 1000L reaction kettle with a pump, stir at 350r / min, react at 150°C for 5h, cool down, filter with 100 mesh filter cloth, wash the filter cake with water 2-3 times, 250-300 Dry at ℃ for 2 hours to obtain 55 kg of anhydrous calcium sulfate whisker product. Calcium sulfate whiskers have a diameter of 1-10 μm and a length of 50-200 μm.

Embodiment 2

[0021] Weigh 50 kilograms of 200-300 mesh powdered anhydrite, add it in batches to a reaction kettle equipped with 200 liters of 1mol / L dilute sulfuric acid solution, stir and react at 60°C until no bubbles are generated, filter with suction, and filter cake and Add 11.2 kg of magnesium chloride to 700 kg of water, stir evenly, pour it into a 1000L reactor with a pump, stir at 350r / min, react at 160°C for 4 hours, cool down, filter with 100-mesh filter cloth, and wash the filter cake with water for 2- 3 times, drying at 250-300°C for 2 hours to obtain 42 kg of anhydrous calcium sulfate whisker product. Calcium sulfate whiskers have a diameter of 1-10 μm and a length of 50-200 μm.

Embodiment 3

[0023] Weigh 20 kilograms of 200-300 mesh powdered anhydrite and 30 kilograms of 200-300 mesh powdered heavy calcium carbonate, add them in batches to a reactor containing 400 liters of 1mol / L dilute sulfuric acid solution, and stir at 60°C React until no bubbles are formed, filter with suction, add the filter cake and 11.2 kg of magnesium chloride to 700 kg of water, stir evenly, pump them into a 1000L reactor, stir at 350r / min, react at 150°C for 5h, cool down, Suction filter with a 100-mesh filter cloth, wash the filter cake with water 2-3 times, and dry at 250-300°C for 2 hours to obtain 51 kg of anhydrous calcium sulfate whisker product. Calcium sulfate whiskers have a diameter of 1-10 μm and a length of 50-200 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com