Hole opening structure on large-diameter thick-wall container shell and hole opening method

A technology of thick-walled containers and open-hole structures, applied in the direction of reducing greenhouse gases, manufacturing tools, and edge parts of workpieces, etc., can solve the problems of large processing area inside the shell, large non-destructive testing area, and large welding workload, etc., to achieve Reduce the workload of surfacing welding and non-destructive testing area, improve the welding quality and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

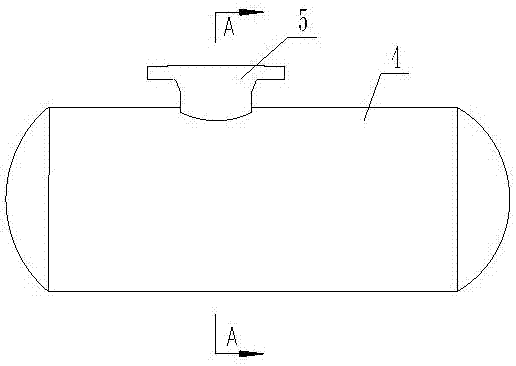

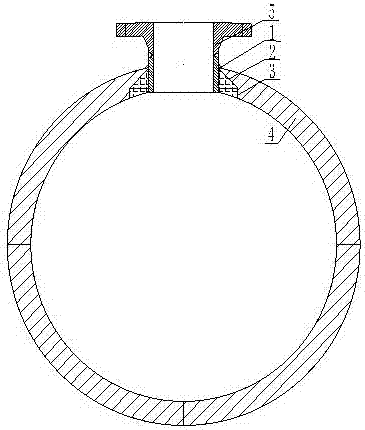

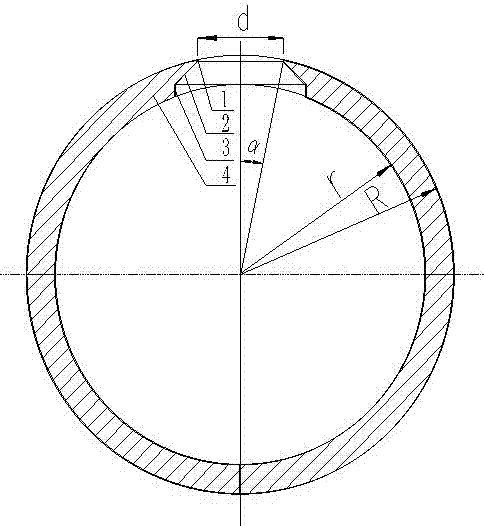

[0032] like figure 1 , 2 , The opening structure shown in 3 and 4 on the shell of the large-diameter thick-walled container, the opening structure is an annular opening structure; Hole 2 and the third straight hole 3. The length of the first straight hole 1 is at least 2mm. The first straight hole 1 communicates with the outside of the housing 4 . The two ends of the second tapered hole 2 are respectively a big end and a small end, the small end is connected to the first straight hole 1 , and the big end is connected to the third straight hole 3 . The third straight hole 3 communicates with the inside of the casing 4 . The angle β between the generatrix of the second section of the tapered hole 2 and the vertical is 45°. The hole depth of the first straight hole 1 is at least 2mm.

[0033] Calculate the busbar length by:

[0034] According to the opening diameter d of the welding hole, the inner radius r of the shell, and the outer radius R of the shell, the angle of th...

Embodiment 2

[0039] In Embodiment 1, the angle β between the generatrix of the second segment of the tapered hole 2 and the vertical line is replaced with 50° from 45°. The calculated length of the tapered hole generatrix is (R *cosα-(r+2)) / cos50°. The three-segment opening is then machined by boring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com