Welding method for sheet type standard knot production line

A welding method and standard section technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of large footprint, unstable quality, low welding efficiency, etc., to reduce land occupation, improve welding quality, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Next, the technical examples of the embodiments of the present application will be described in contemplation in the present application, and is clearly, and it is not intended to be illustrative, and is not intended to limit the present application.

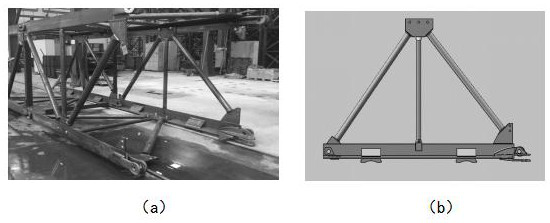

[0034]Such asfigure 1 As shown, the sheet-based standard section sheet welding assembly of the present invention includes three round tube diagonal lesters, and the diagonal lever is connected by a connecting plate. The other segment of the oblique belling is connected to the corner iron main limbs, including the left and right sides. The two oblique belts are connected to both ends of the main limbs by a triangular plate, and one intermediate diagonal belt is vertically connected to the middle of the main limbs, and the left and right oblique belts are symmetrical. The main limbs are provided with a corner iron main limbs and Step, there is a fish tail plate on both sides.

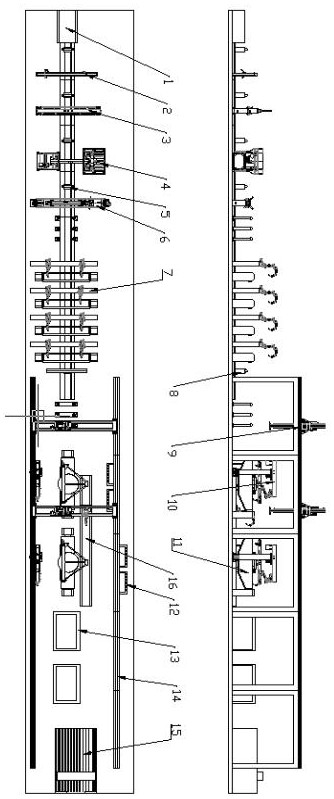

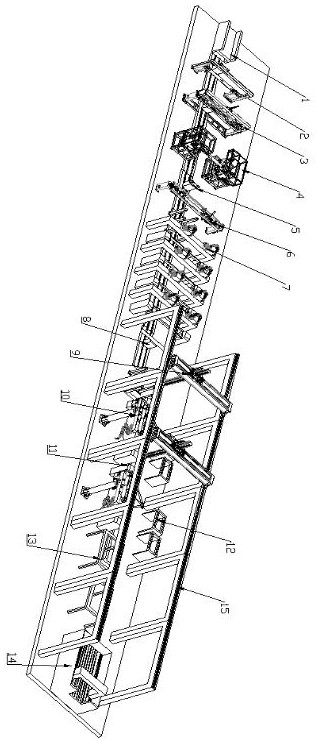

[0035]In the front of the front angle iron length of 9 mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com