Fruit juice milk tea beverage based on high proteins and preparation method thereof

A high-protein, fruit juice technology, applied in the food field, to achieve the effect of ensuring the feasibility of normal continuous production, realizing the production process and packaging mode, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

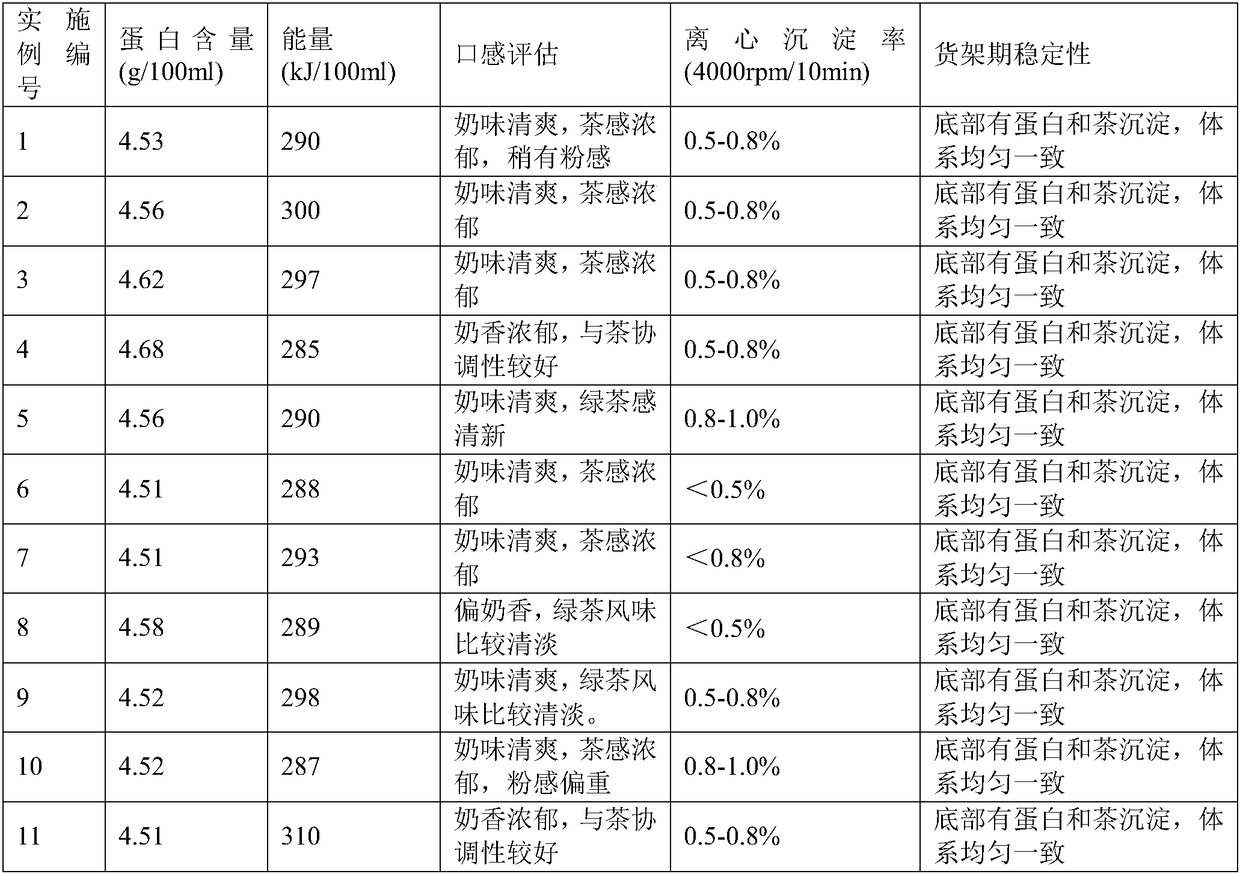

Examples

Embodiment 1

[0062] The weight of each composition of the present embodiment is counted as: 45 grams of casein, 2 grams of wheat protein powder, 2 grams of soybean protein powder, 2 grams of rice protein powder, 15 grams of coconut milk, 30 grams of white granulated sugar, crystallization 20 grams of fructose, 6 grams of black tea leaves, 1 gram of black tea powder, 2 grams of concentrated strawberry juice, 1.0 grams of glyceryl monostearate, 0.5 grams of sucrose fatty acid esters, 0.3 grams of carrageenan, 0.5 grams of gellan gum, and 0.1 grams of vitamin E gram, 0.5 gram of sodium tripolyphosphate, 0.5 gram of sodium erythorbate, 0.5 gram of sodium bicarbonate, 0.1 gram of nisin, and the balance is purified water.

[0063] The production process is: preparation of milk liquid (dissolving milk with emulsifier and protein raw materials)→hydration homogenization→stabilizer dissolution→tea soup extraction or tea powder dissolution and callback→juice dissolution treatment→syrup dissolution→ing...

Embodiment 2

[0076] The weight of each composition of the present embodiment is counted as total amount 1000 milliliters: the consumption of each composition is as follows: 35 grams of casein, 40 grams of whole milk powder, 2 grams of wheat protein powder, 2 grams of soybean protein powder, 2 grams of rice protein powder , 5 grams of coconut milk, 15 grams of white sugar, 25 grams of crystalline fructose, 6 grams of black tea leaves, 1 gram of black tea powder, 2 grams of concentrated strawberry juice, 1.0 grams of glyceryl monostearate, 1.0 grams of diacetyl tartaric acid mono-diglycerides , Carrageenan 0.35g, Microcrystalline Cellulose 1.0g, Vitamin E 0.1g, Sodium Tripolyphosphate 0.5g, Sodium Citrate 0.2g, Sodium Erythorbate 0.5g, Sodium Bicarbonate 1.0g, Nisin 0.1g, The balance is purified water.

[0077] The production process is: preparation of milk liquid (dissolving milk with emulsifier and protein raw materials)→hydration homogenization→stabilizer dissolution→tea soup extraction o...

Embodiment 3

[0091] The weight of each composition of the present embodiment is counted as total amount 1000 milliliters: the consumption of each composition is as follows: 37 grams of casein, 25 grams of skimmed milk powder, 2 grams of wheat protein powder, 2 grams of soybean protein powder, 2 grams of rice protein powder, 15 grams of coconut milk, 40 grams of crystalline fructose, 6 grams of black tea leaves, 1 gram of black tea powder, 0.5 grams of concentrated lemon juice, 0.8 grams of glyceryl monostearate, 0.3 grams of sucrose fatty acid esters, 0.3 grams of carrageenan, gellan gum 0.2 g, 0.1 g of ascorbic acid, 0.3 g of sodium tripolyphosphate, 0.2 g of sodium hexametaphosphate, 0.5 g of sodium erythorbate, 0.9 g of sodium bicarbonate, 0.1 g of nisin, and the balance is purified water.

[0092] The production process is: preparation of milk liquid (dissolving milk with emulsifier and protein raw materials)→hydration homogenization→stabilizer dissolution→tea soup extraction or tea pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com