Automatic high-speed sticking equipment of elastic key pieces

A button and shrapnel technology, applied in the field of automatic high-speed button shrapnel sticking equipment, can solve the problems of unreliable pasting, high repetitive operation intensity, reduced production efficiency, etc., to meet the requirements of large-order production, ensure product quality stability, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

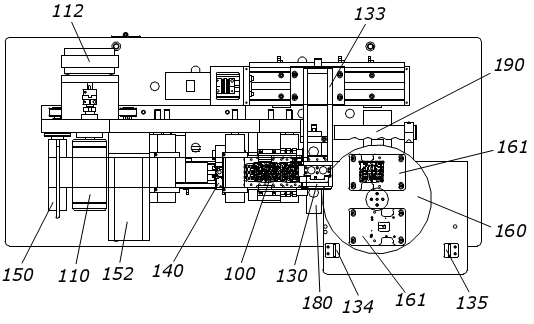

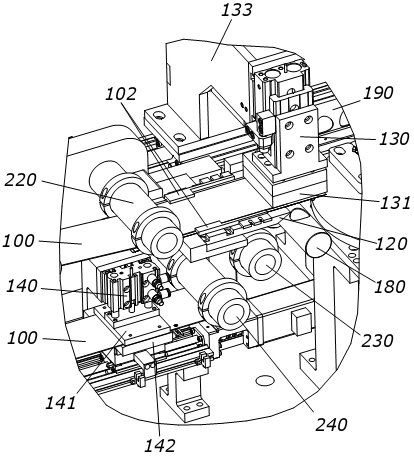

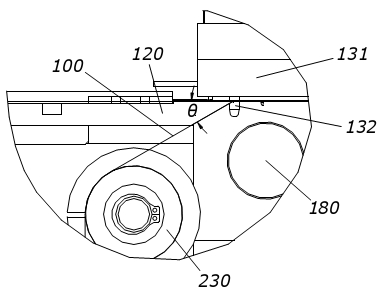

[0025] The present invention is an automatic high-speed key spring pasting device, which is used to peel off the key spring from its material tape and paste it on the corresponding circuit board. Multi-button style; such as figure 1 As shown, the automation equipment at least includes a discharge device, a suction and pressure device and a coil device, wherein: the discharge device includes an unwinding roller 110, which is used to install and unwind the roll-shaped material tape 100, the material tape 100 is pasted with a button shrapnel; the strip 100 enters the stripping device after passing through the nip roller and / or the transition roller (210 and 220); the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com