Ti (C, N)-based metal ceramic cutter material and preparation method thereof

A ceramic cutting tool and base metal technology, applied in the field of cermet materials, can solve the problems such as fracture toughness and flexural strength need to be further improved, flexural strength needs to be further improved, etc., to achieve grain refinement, performance improvement, and extended overall use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail in conjunction with specific embodiments.

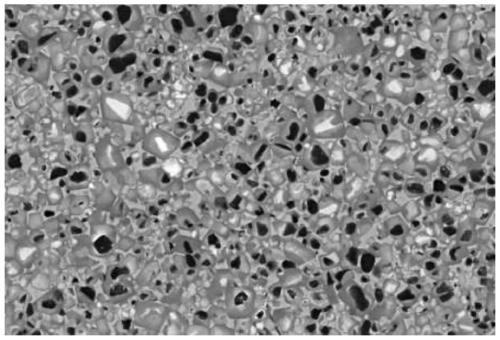

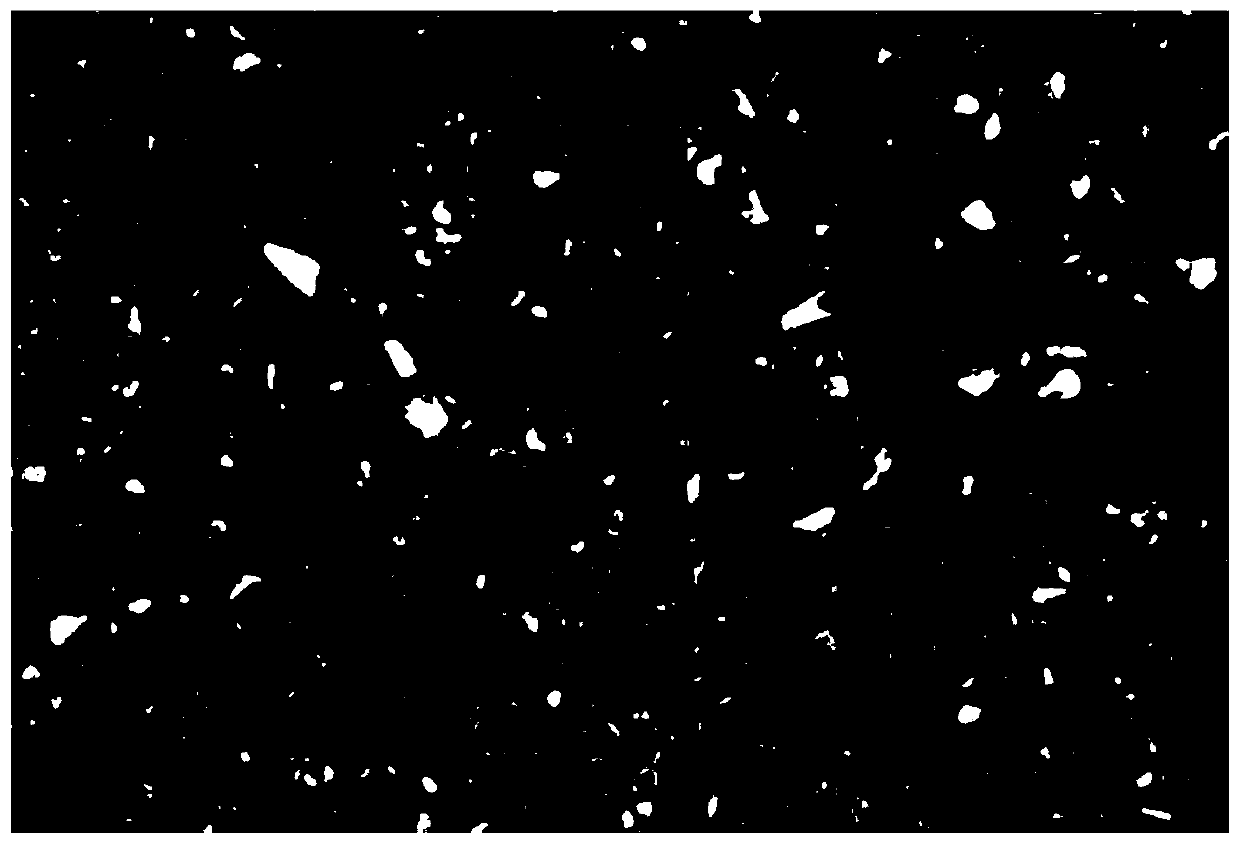

[0043] A preparation method of Ti(C,N)-based cermet cutting tools, each hard phase and bonding metal are weighed according to the ratio: Ti(C 0.5 ,N 0.5 ),(Ti 39.8 W 46.9 )C,TiC,Mo 2 C, TaC, TiC, VC, Co, Ni and carbon black, put the weighed raw materials into a rolling ball mill for ball milling and mix them evenly. Ti(C 0.5 ,N 0.5 ), (Ti 39.8 W 46.9 ) C, WC, Mo 2 The raw material size of C, TaC, TiC and VC is 0.5-2 μm, and the raw material size of Co and Ni is 1-3 μm. Each raw material content of embodiment 1~9 is as shown in table 1:

[0044] Table 1 Raw material composition

[0045] Numbering Ti(C 0.5 ,N 0.5 )

(Ti 39.8 W 46.9 )C

WC TiC Mo 2 C

TaC VC co Ni C Example 1 21.5% 34.5% 0 11.3% 10.5% 6.2% 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com