Die for forging production of aluminum alloy control arms

A control arm and aluminum alloy technology, applied in the field of auto parts, can solve problems such as unstable product quality, dissatisfied filling, inaccurate positioning of blanks, etc., to ensure product quality stability, increase metal utilization, and reduce processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

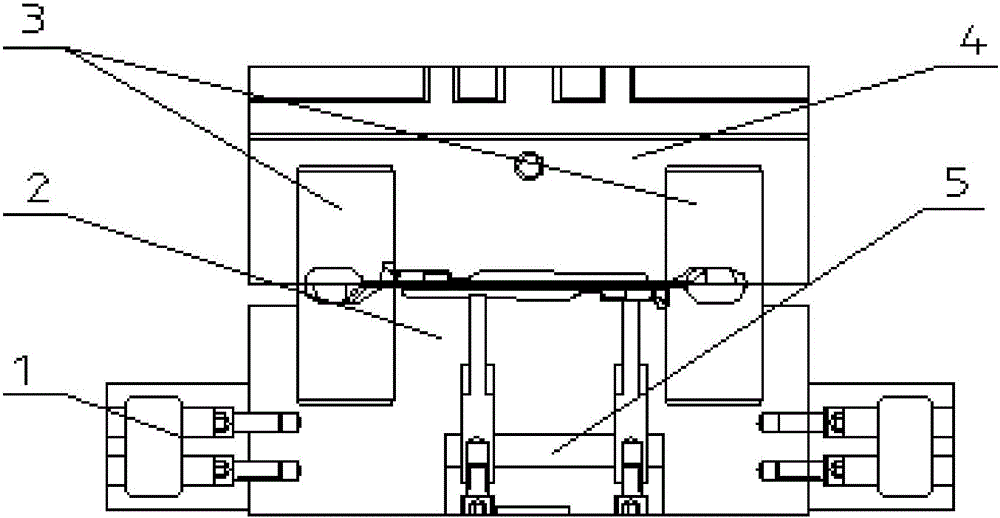

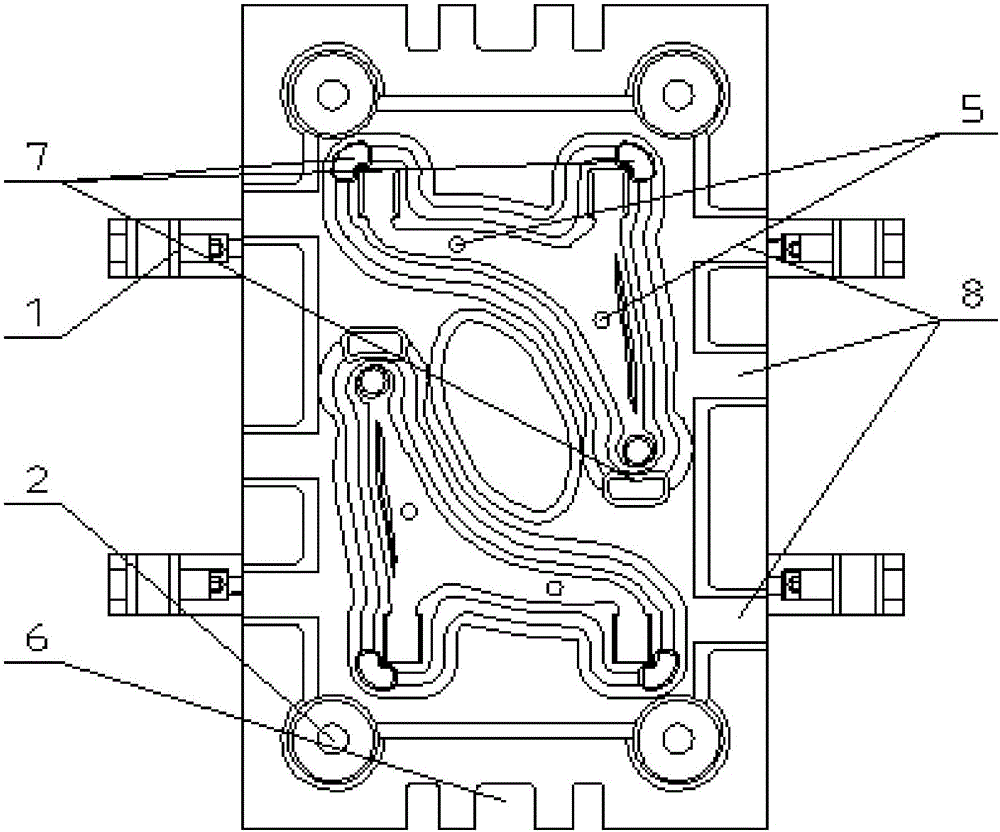

[0016] The mold of this embodiment is made up of upper mold (4), guide post (3) and lower mold (2), and it is characterized in that: the both sides of described lower mold (2) are connected mold lifting beam (1); The mold (4) and the lower mold (2) are connected by guide columns (3); the bottom of the lower mold (2) is equipped with a multi-link ejector (5), and it is set to simultaneously eject the product; the front and rear positions of the upper mold (4) and the lower mold (2) are provided with mold installation guide grooves (6), and are set to fix the mold on the equipment workbench; the upper mold (4) and the The lower mold (2) jointly defines a mold cavity, and a blank positioning groove (7) is arranged in the mold cavity, and the blank positioning groove is set to fix the position of the blank; the side of the lower mold (4) is provided with a blank clamp A holding guide groove (8), the blank holding guide groove (8) is set towards the side of the blank. The processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com