Friction stir welding method for aluminum alloy with fusion welding positioning welding seams

A technology of friction stir welding and tack welding, which is applied in the direction of welding/welding/cutting items, welding equipment, non-electric welding equipment, etc. It can solve the problems of difficult control of the joint group gap, unstable welding quality of friction stir welding, and high tooling requirements. , to achieve the effect of solving strict assembly clearance requirements, improving stability, product qualification rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

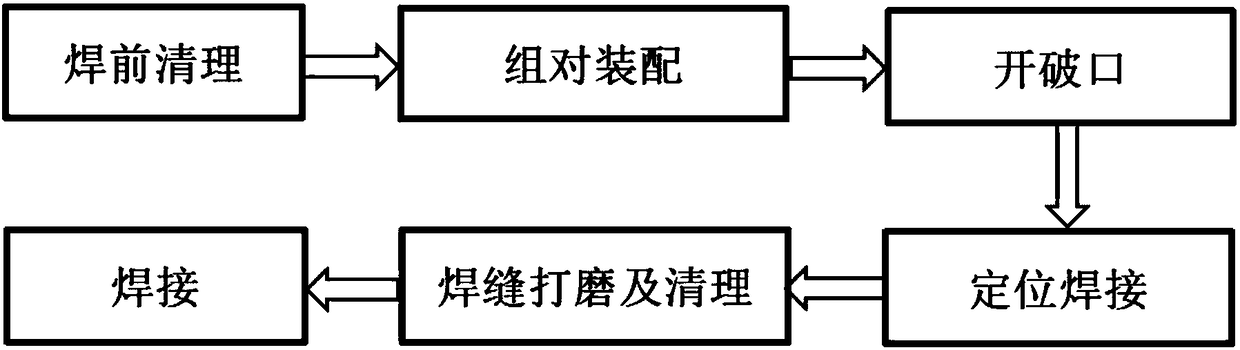

[0034] A kind of friction stir welding method of aluminum alloy with fusion welding tack weld figure 1 As shown, the method includes the following steps:

[0035] The specifications of the welding material of the workpiece to be welded are 6005A-T6 aluminum alloy extruded profiles of 2000mm*150mm*6mm, and the mass fraction of its chemical composition is shown in Table 1:

[0036] Table 1

[0037] Si

Mg

Fe

Cu

mn

Cr

Ti

Zn

Al

other

0.66

0.53

0.16

0.14

0.26

0.16

0.02

0.02

98.02

margin

[0038] A. Cleaning before welding:

[0039] a. Pre-cleaning: Use non-woven fabric to dip acetone or ethanol on the groove surface of the joint of two 6005A-T6 aluminum alloy profiles to be welded and the nearby 25mm area to clean the oil and dust on the surface of the workpiece to be welded;

[0040] b. Removal of oxide film: use an electric wire bowl brush to polish the groove surface of the welded joint of the pr...

Embodiment 2

[0052] The difference between embodiment 2 and embodiment 1 is that the welding process parameters of MIG fusion welding in step D are as shown in table 4:

[0053] Table 4

[0054] Welding method

Wire diameter

Welding current

welding voltage

welding speed

Argon flow

MIG

ER5356

1.2mm

120A

19V

400mm / min

23L / min

[0055] The welding process parameters of friction stir welding in step F are as shown in Table 5:

[0056] table 5

[0057] Welding method

Embodiment 3

[0059]The difference between embodiment 3 and embodiment 1 is that the welding process parameters of MIG fusion welding in step D are as shown in table 6:

[0060] Table 6

[0061] Welding method

Wire diameter

Welding current

welding voltage

welding speed

Argon flow

MIG

ER5356

1.2mm

150A

20V

500mm / min

27L / min

[0062] The welding process parameters of friction stir welding in step F are as shown in Table 7:

[0063] Table 7

[0064] Welding method

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com