On-line quenching and plate shape controlling technology for 12MnNiVR steel plate

A technology of shape control and steel plate, applied in manufacturing tools, tail end control, metal rolling, etc., can solve the problem of low cooling efficiency, and achieve the effect of improving cooling efficiency, reducing hoisting, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

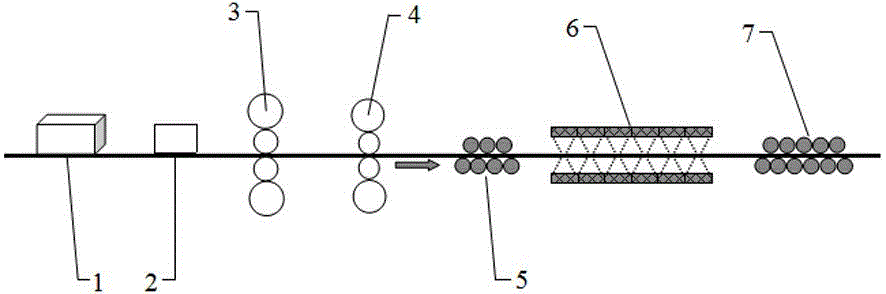

[0032] The size of the 12MnNiVR billet in this example is 220mm*2060mm*2619mm, and the size of the finished steel plate is 20.69mm*2085mm*27571mm. Considering the shot blasting process before tempering, rolling with a positive tolerance is adopted, with a total of 13 rolling passes and 7 rough rolling passes. , Finish rolling 6 passes. The schematic diagram of the layout of the double-stand medium and heavy plate rolling line is as follows figure 1 As shown, heating furnace 1, descaling box 2, 2800mm four-high reversible roughing mill 3, 2690mm four-high reversible finishing mill 4, pre-leveler 5, ultra-fast cooling system 6, hot leveler 7 are set in sequence, and the billet The specific processing steps are as follows.

[0033] (1) The chemical composition weight percent of the 12MnNiVR steel plate is: C: 0.085~0.11, Si: 0.16~0.3, Mn: 1.4~1.5, P: 0~0.013, S: 0~0.003, Cr: 0~0.08, Cu: 0~0.06, Mo: 0.08~0.13, Nb: 0~0.01, V: 0.04~0.055, Ti: 0.007~0.03, Ni: 0.22~0.26, Alt: 0.01~0...

Embodiment 2

[0057] The size of the 12MnNiVR blank in this embodiment is 220mm*2060mm*2510mm, and the size of the finished steel plate is 32.6mm*2525mm*13842mm. The operation that it adopts is basically the same as embodiment 1, and the difference is:

[0058] Also includes

[0059] (1) The chemical composition weight percentage of 12MnNiVR billet is: C: 0.0952, Si: 0.1958, Mn: 1.4301, P: 0.0117, S: 0.002, Cr: 0.0429, Cu: 0.0353, Mo: 0.0888, Nb: 0.0018, V: 0.0439, Ti: 0.011, Ni: 0.2335, Alt: 0.0196, and the rest are Fe and unavoidable impurities.

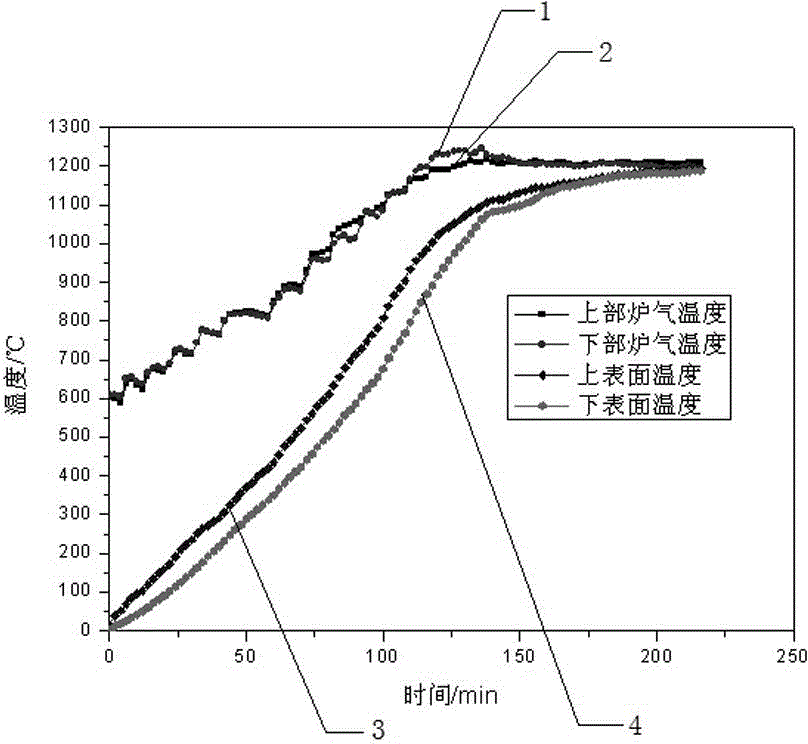

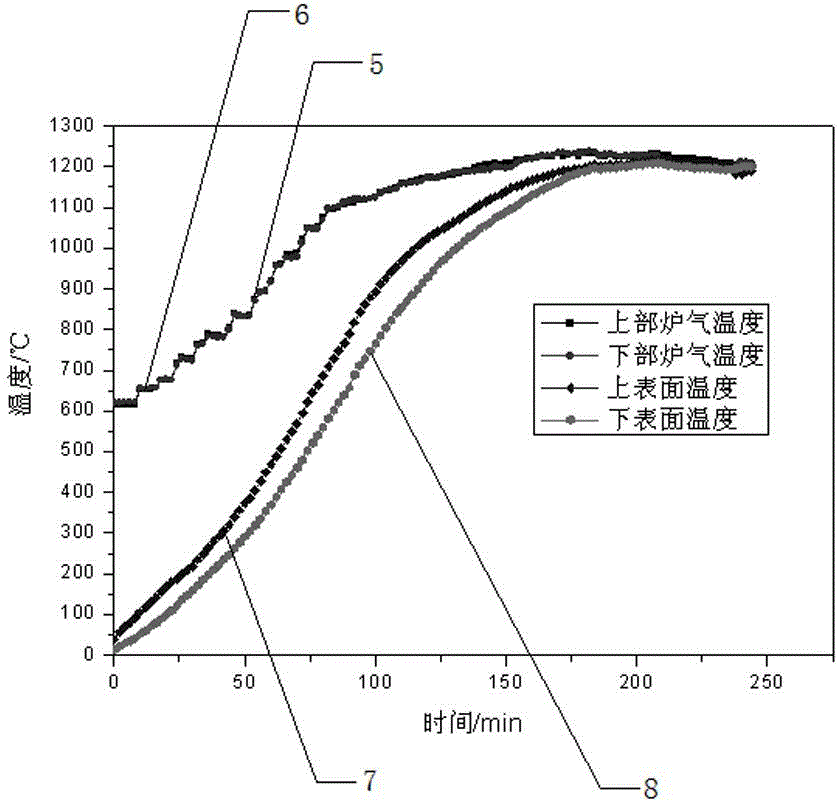

[0060] (2) Billet cold charging step: the billet is cooled for 71.9 hours before steel loading, the furnace gas temperature in the heat recovery section of heating furnace 1 is 615~989°C, the furnace gas temperature in the first heating section is 1014~1111°C, and the furnace gas temperature in the second heating section is 1110°C ~1209℃, furnace gas temperature in the third heating section 1198~1235℃, furnace gas temperature in the soaking se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com