Composite material panel array hole detection method based on line laser scanning

A detection method, line laser technology, applied in the field of digital measurement, can solve problems such as difficulty in product acceptance, low confirmation efficiency, affecting production tact and delivery progress, etc., to shorten the delivery cycle, avoid misjudgment, and reliable detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

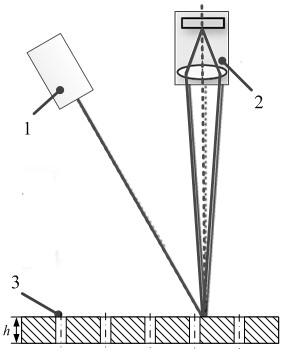

[0034] A method for detecting array holes in composite wall panels based on line laser scanning, such as figure 1 As shown, the laser 1 is used to project a line laser to the surface of the measured object 3, and the laser stripes passing through the surface of the measured object 3 are collected by the industrial camera 2, and then the data of the outer surface of the wall panel and the data of the bottom of the hole are obtained, and the point cloud data obtained from the scan Obtain hole section data row by row in:

[0035] ① If the distance between the point cloud data at the bottom of the hole in the cross-sectional point cloud data and the upper surface of the measured panel is all less than the thickness h of the panel, it is considered that the hole is blocked, for example Figure 5 The first measured hole 6 in the

[0036] ②If the distance between the point cloud data at the bottom of the cross-sectional point cloud data and the upper surface of the measured object 3...

Embodiment 2

[0042] This embodiment is optimized on the basis of Embodiment 1. For the suspected blockage situation, continue to extract the adjacent sections of the current section. The extraction of the section covers the entire aperture range. If it still cannot be judged as a through hole, that is, if it meets the requirements of the section If the distance between the point cloud data of the hole bottom of the point cloud data and the upper surface of the measured wall plate is less than the thickness of the wall plate or the distance between the point cloud data and the upper surface of the measured object 3 is less than the thickness h of the wall plate, then the hole position is considered to block the hole, i.e. no conduction

[0043] Other parts of this embodiment are the same as those of Embodiment 1, so details are not repeated here.

Embodiment 3

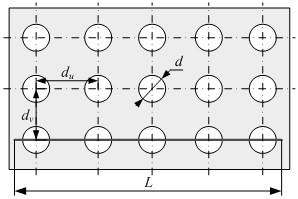

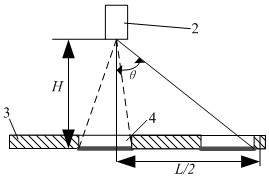

[0045] This embodiment is optimized on the basis of embodiment 1 or 2, as figure 2 , image 3 As shown, an industrial camera 2 is used to measure the measured hole 4, and the laser stripe at the bottom of the measured hole 4 can be photographed, and the length L of the laser stripe is greater than or equal to the size of the covered hole.

[0046] Further, the length L of the laser stripes:

[0047] L≥d u ×(n-1)+d

[0048] And should meet:

[0049]

[0050] Among them, d is the aperture, d u is the horizontal spacing, d v is the vertical spacing, h is the depth, n is the number of holes; H is the distance from the industrial camera 2 to the bottom of the measured hole 4, and θ is the angle between the axis of the optical path and the normal vector of the hole.

[0051] Other parts of this embodiment are the same as those of Embodiment 1 or 2 above, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com