Substrate carrying in/out apparatus, substrate carrying method and device thereof

A substrate handling and substrate technology, which is applied in the field of substrate devices, can solve the problems that are not suitable for the manufacture of products with short lead times, the production time cannot be achieved, and the turnover rate (recovery rate becomes poor, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

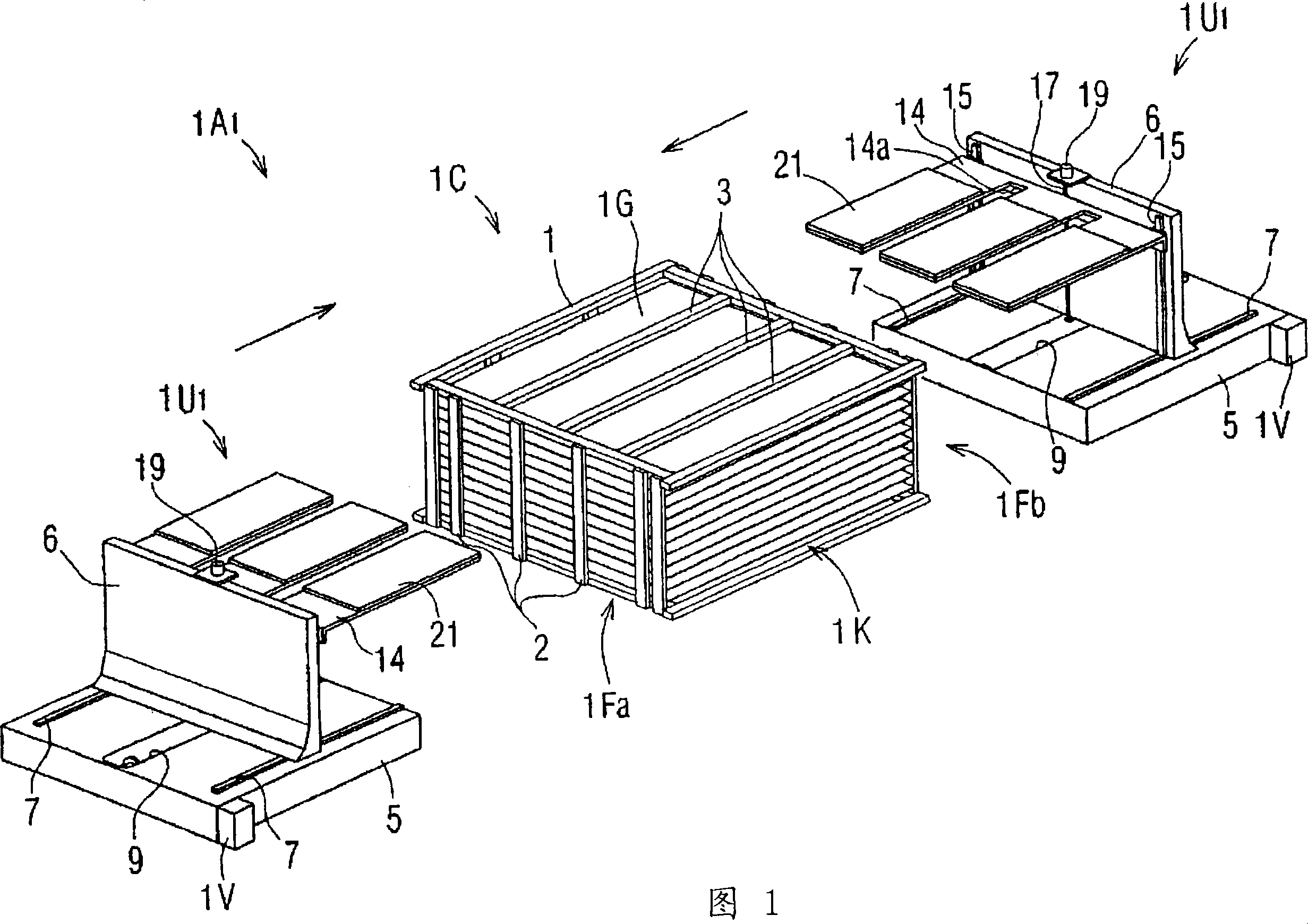

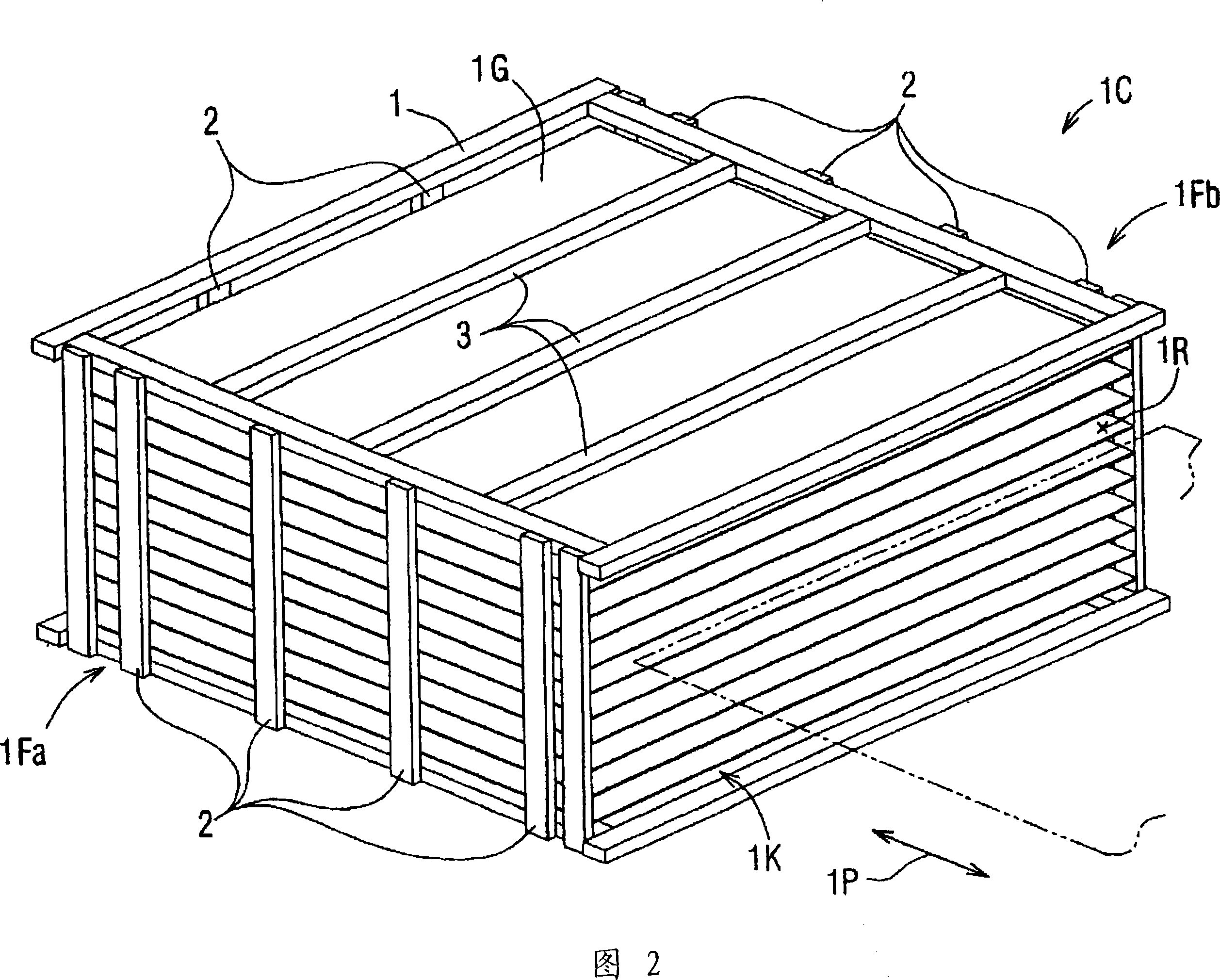

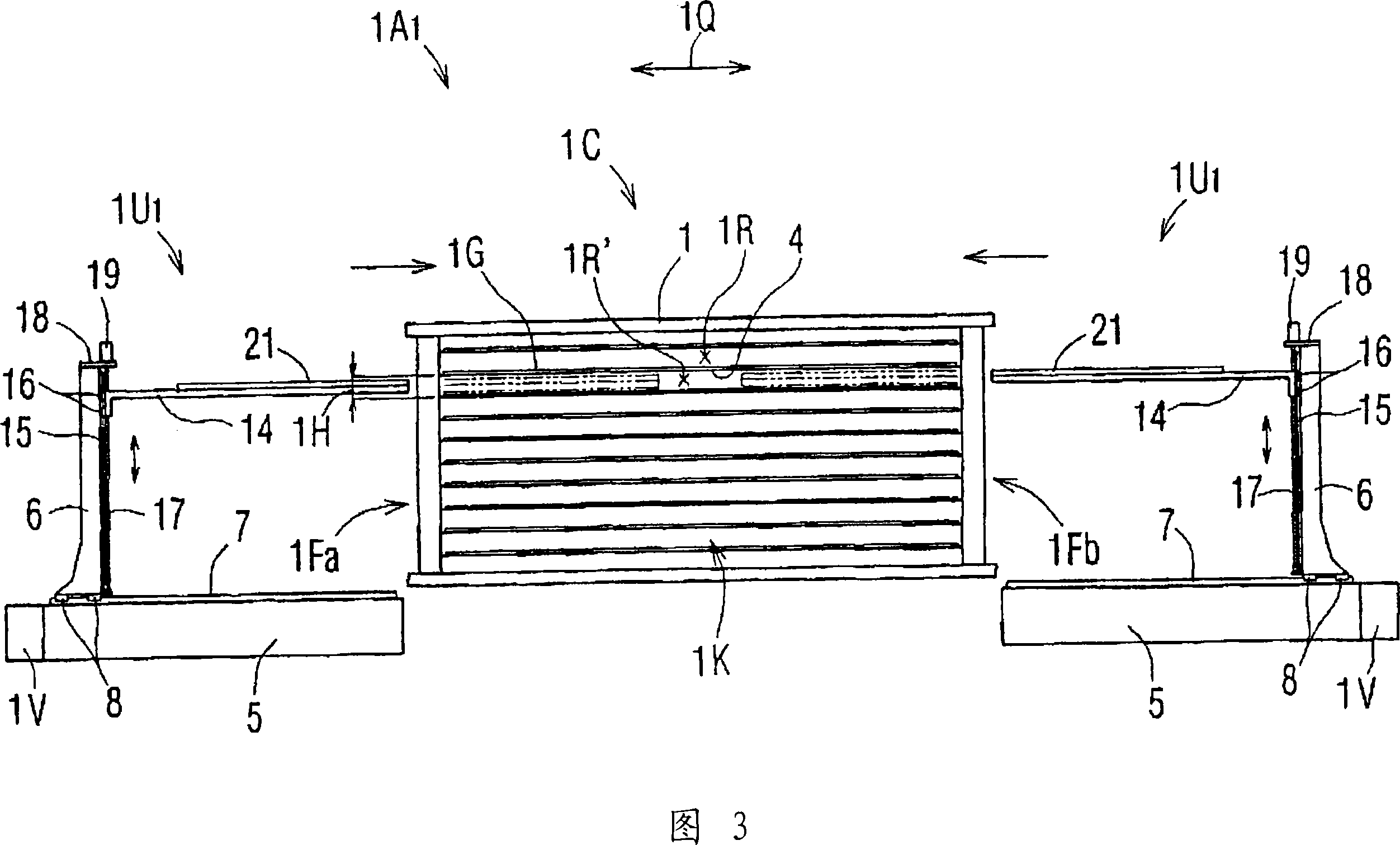

[0132] First, the board loading / unloading device of the present invention will be described based on the first to third embodiments.

[0133] 1 is an overall perspective view of a substrate loading and unloading device 1A1 according to the first embodiment of the present invention, FIG. 2 is a perspective view of a substrate box 1C, FIG. 3 is a front view of the substrate loading and unloading device 1A1 of the first embodiment, and FIG. 4 is a pair of 5 is a plan view of the substrate take-out device 1B, and FIG. 6 is a side sectional view of the substrate take-out device 1B.

[0134] As shown in FIGS. 1 and 3 , the substrate loading / unloading apparatus 1A1 of the first embodiment includes a substrate box 1C and a pair of side surfaces 1Fa adjacent to a specific side surface (loading / unloading opening 1K) of the substrate 1G of the substrate box 1C, Each substrate elevating unit 1U1 arranged in 1Fb is constituted. A compressed air source 1V for supplying compressed air is at...

no. 2 example

[0151] The above-mentioned substrate loading and unloading apparatus 1A1 of the first embodiment is a system in which a pair of substrate elevating units 1U1 are arranged with respect to one substrate case 1C, and a method in which the substrate elevating arms 14 enter from both side surfaces 1Fa and 1Fb of the substrate case 1C, respectively. . However, as shown in FIG. 9 , a substrate loading / unloading device 1A2 composed of one substrate box 1C and one substrate elevating unit 1U2 may also be used. In the substrate loading / unloading apparatus 1A2 of the second embodiment, there is an advantage that the substrate elevating unit 1U2 is constituted by one. In addition, the substrate loading / unloading apparatus 1A2 shown in FIG. 9 is a form in which the substrate lifting arm 34 of the substrate lifting unit 1U2 enters from the side surface 1Fa of one side of the substrate box 1C. However, the elevating arm 34 may enter from the other side surface 1Fb of the substrate box 1C, t...

no. 3 example

[0153] In addition, in the substrate elevating unit 1U3 shown in FIG. In the pair of substrate elevating units 1U3 constituting the substrate loading / unloading apparatus 1A3 of the third embodiment, each air floating unit 21 is attached to each substrate elevating arm 35 , and air piping is formed so that they operate independently. road. In addition, each substrate lifting arm 35 is attached to the movable machine frame 6 in a single-arm state. And the air piping line is switched by the switching apparatus which is not shown in figure so that only the air-floating unit 21 corresponding to the specific board|substrate 1G may discharge compressed air. Then, only a specific substrate 1G floats among the substrates 1G supported in multiple stages, and this substrate 1G is carried out by the substrate take-out device 1B. Moreover, when carrying in the board|substrate 1G, pressurized air is ejected only from the air float corresponding 21 corresponding to the rack 1R which carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com