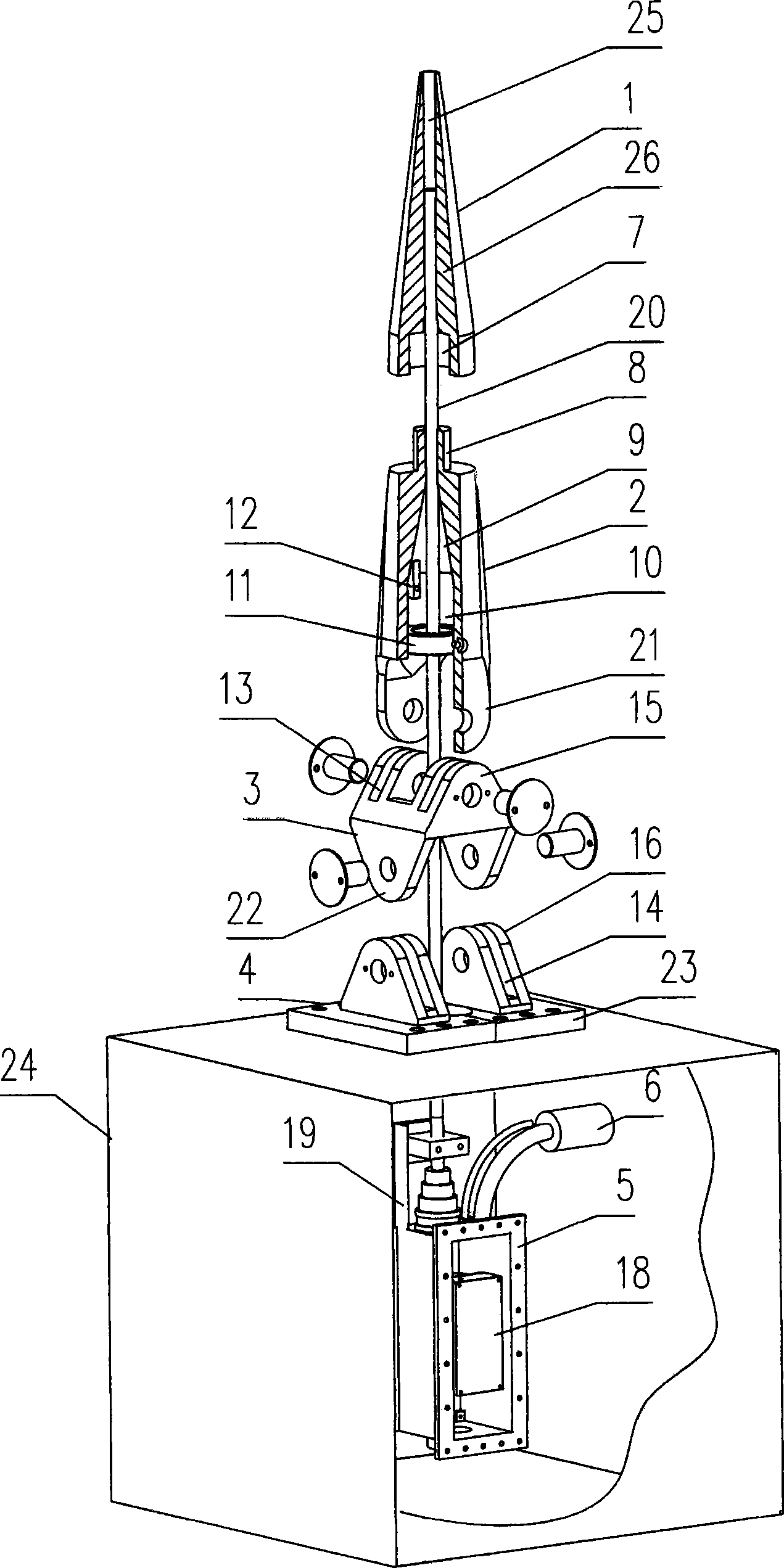

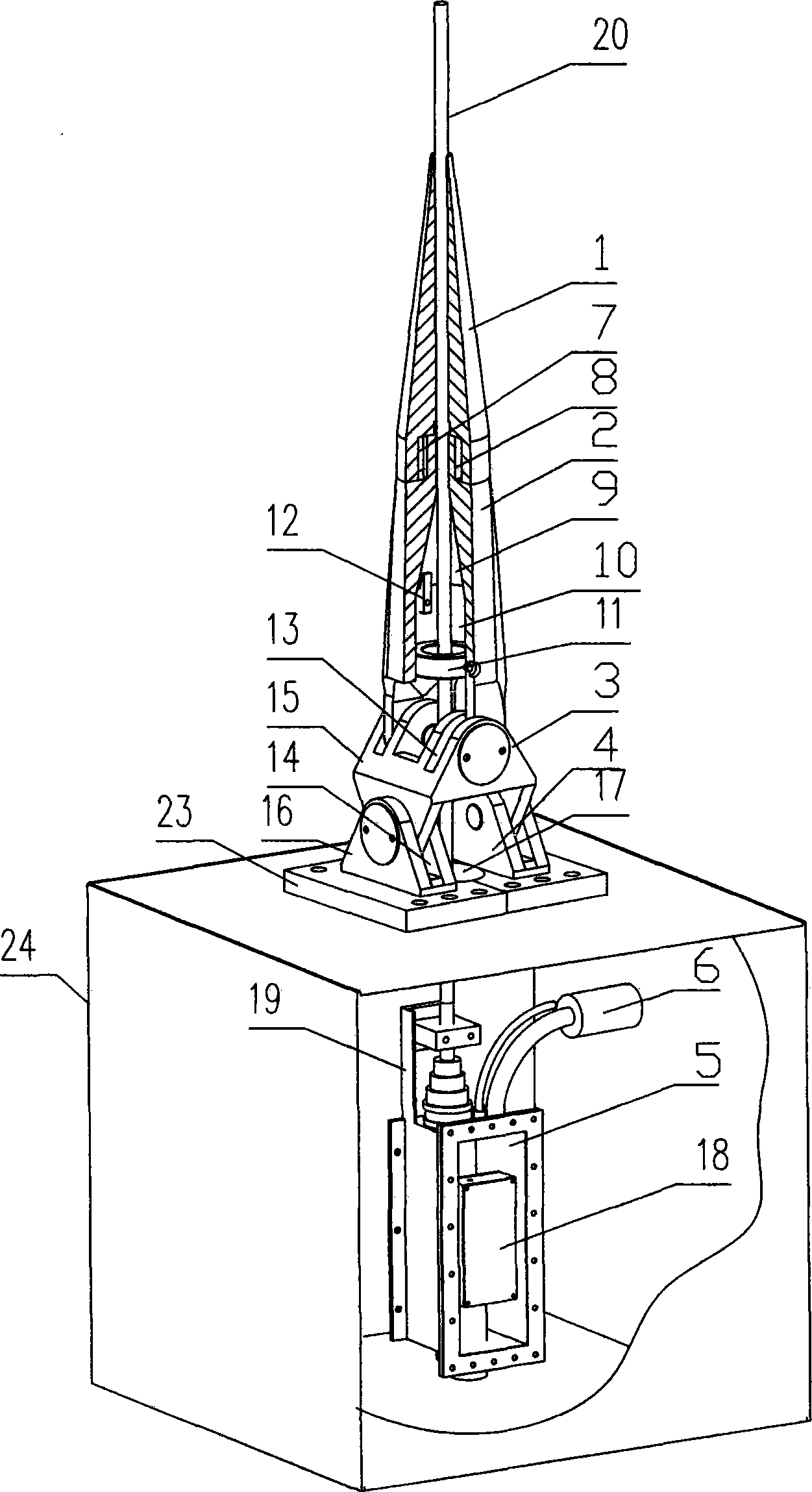

Universal bearing device for connecting steel cable and outboard surveying device and manufacturing method thereof

A technology of equipment connection and load-bearing device, which is applied to cable joints, mechanical equipment, textile cables, etc., can solve the problems of large impact force, inconsistent watertight connectors at the joint head, and cannot be recycled, and achieves lower production costs, convenient signal connection, The effect of shortening the lead time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0066] Embodiment 2: The manufacturing method of the universal load-bearing device that the working cable is connected with the marine survey equipment: the following steps are provided:

[0067] 1) Pretreatment of working cables

[0068] (1) prepare segmented steel cable joints:

[0069] The connector of the steel cable is divided into 3 sections, from the end to the top: the first section is 50cm long, which is the core cable exposed after peeling off the outer steel wire and insulation layer, and this section is ready to be connected to the junction box; the second section In order to peel off the outer steel wire and expose the core cable of the insulation layer, this section is prepared to be placed inside the working equipment, and its length is the distance from the load-bearing part to the junction box. The length of this section is consistent with the needs of the user's equipment; the third section is 0.2 meters Long, the outer steel wire is scattered, ready to be c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Splice loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com