High-strength weathering steel thin strip and production method thereof

A production method and weather-resistant steel technology, applied in the field of weather-resistant steel thin strips, can solve the problems of long production process, poor welding performance, and low production efficiency of high-strength weather-resistant steel thin strips, so as to reduce volume change, improve welding performance, The effect of increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

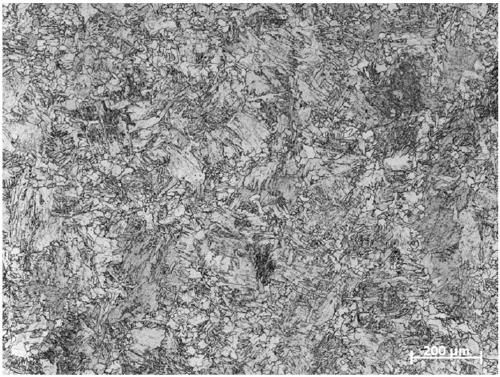

Image

Examples

Embodiment 1

[0036] This embodiment proceeds according to the following steps:

[0037] 1) Smelting

[0038] The chemical composition of molten steel is: C: 0.020wt%, Si: 0.30wt%, Mn: 1.80wt%, P: 0.01wt%, S: 0.002wt%, Cr: 0.40wt%, Cu: 0.50wt%, Nb: 0.10 wt%, the rest is iron and unavoidable impurities;

[0039] 2) Thin strip continuous casting

[0040] The molten steel qualified for smelting is continuously cast into a casting strip with a thickness of 2.0mm through a pair of oppositely rotating casting rollers; the superheat of the molten steel is 60°C;

[0041] 3) On-line hot rolling of cast strip

[0042] The cast strip is rolled into thin strip steel after one pass of hot rolling, the hot rolling reduction is 50%, and the temperature of the strip steel before entering the hot rolling mill is 980°C;

[0043] 4) Cooling and coiling

[0044] The hot-rolled strip is cooled to 620°C by gas-mist cooling and coiled into coils.

[0045] The thickness of the thin strip of weathering steel ...

Embodiment 2

[0047] This embodiment proceeds according to the following steps:

[0048] 1) Smelting

[0049] The chemical composition of molten steel is: C: 0.028wt%, Si: 0.25wt%, Mn: 1.60wt%, P: 0.008wt%, S: 0.0022wt%, Cr: 0.45wt%, Cu: 0.90wt%, Nb: 0.22 wt%, the rest is iron and unavoidable impurities;

[0050] 2) Thin strip continuous casting

[0051] The molten steel qualified for smelting is continuously cast into a casting strip with a thickness of 2.4mm through a pair of oppositely rotating casting rollers; the superheat of the molten steel is 40°C;

[0052] 3) On-line hot rolling of cast strip

[0053] The cast strip is rolled into thin strip steel after one pass of hot rolling, the hot rolling reduction is 62.5%, and the temperature of the strip steel before entering the hot rolling mill is 1058°C;

[0054] 4) Cooling and coiling

[0055] The hot-rolled strip is cooled to 460°C by gas-mist cooling and coiled into coils.

[0056] The thin strip of weathering steel obtained throu...

Embodiment 3

[0058] This embodiment proceeds according to the following steps:

[0059] 1) Smelting

[0060] The chemical composition of molten steel is: C: 0.025wt%, Si: 0.20wt%, Mn: 1.40wt%, P: 0.012wt%, S: 0.0023wt%, Cr: 0.48wt%, Cu: 0.70wt%, Nb: 0.18 wt%, the rest is iron and unavoidable impurities;

[0061] 2) Thin strip continuous casting

[0062] The molten steel qualified for smelting is continuously cast into a casting strip with a thickness of 1.6mm through a pair of oppositely rotating casting rollers; the superheat of the molten steel is 20°C;

[0063] 3) On-line hot rolling of cast strip

[0064] The cast strip is rolled into thin strip steel after one pass of hot rolling, the hot rolling reduction is 25%, and the temperature of the strip steel before entering the hot rolling mill is 1020°C;

[0065] 4) Cooling and coiling

[0066] The hot-rolled strip was cooled to 520°C by gas-mist cooling and coiled into coils.

[0067] The thin strip of weathering steel obtained thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com