Hydrojet pretreatment method for accelerating stabilization of rust layer on surface of weathering resistant steel

A technology of surface treatment agent and weathering steel, applied in the field of steel anti-corrosion, which can solve the problems of high cost and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, the verification based on the weathering steel surface pretreatment technology in the spray accelerated experiment includes the following steps:

[0020] Step 1. Cut the weathering steel into 50mm×50mm, after degreasing with acetone, clean it with absolute ethanol and dry it;

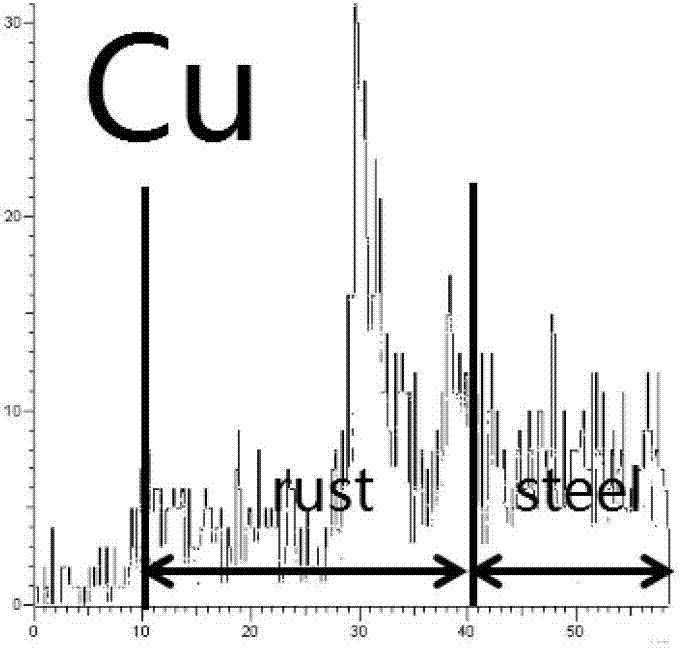

[0021] Step 2. Prepare 100g weathering steel surface treatment solution (0.6%NaCl+0.9%FeSO 4 +0.6%CuSO 4 +

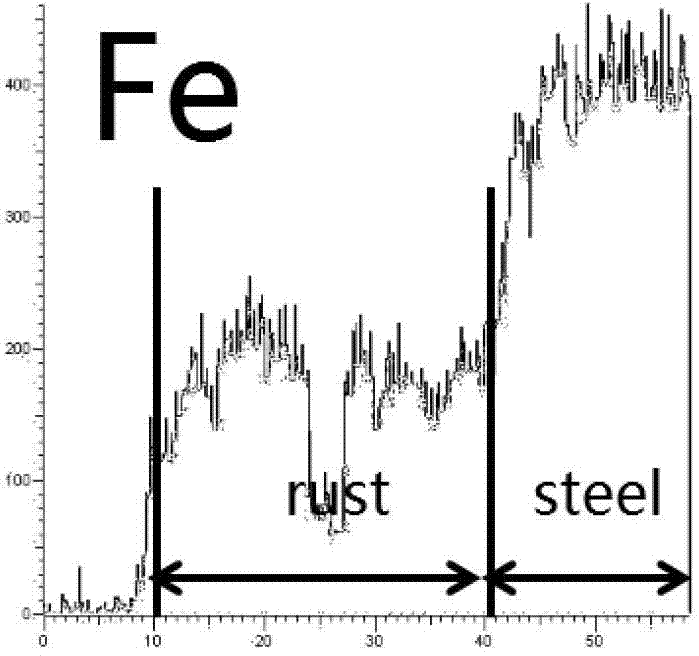

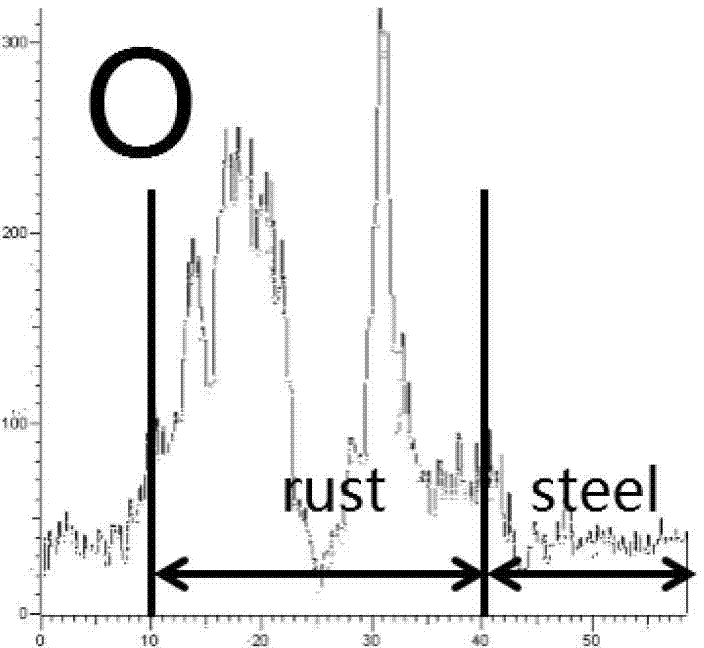

[0022] 0.9%NaHSO 3 ). Use the prepared weathering steel pretreatment solution to spray the weathering steel sample. After the surface of the sample is dry, repeat the spraying treatment solution twice, and then spray the treated sample with clean water to remove floating rust, and use a scanning electron microscope Observe the morphology of the cross-section of the rust layer, and analyze the element distribution in the rust layer with energy spectrum;

[0023] Step 3. Spray 0.5% NaCl on weathering steel after surface pretreatment and bare steel without surface tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com