Weathering steel with low yield ratio and high strength and production method of weathering steel

A technology with low yield ratio and production method, which is applied in the field of metallurgy, can solve the problems of low strength level, easy brittle failure, scrapping of metal equipment and materials, etc., and achieve the effect of improving strength, toughness, shock resistance and ensuring corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

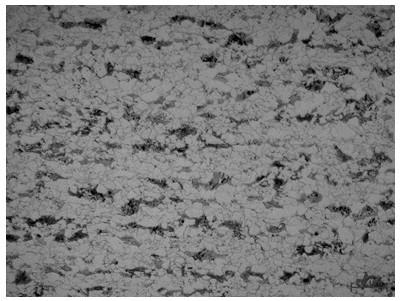

Image

Examples

Embodiment 1

[0039] The thickness of the low-yield-ratio high-strength weathering steel in this example is 10mm, and its chemical composition and mass percentage are shown in Table 1.

[0040] The production method of the high-strength weathering steel with low yield ratio in this embodiment includes smelting, continuous casting, slab heating, controlled rolling, and controlled cooling. The specific process steps are as follows:

[0041] (1) Smelting and continuous casting process: After smelting, the molten steel is continuously cast into a slab, and the thickness of the slab is 150mm;

[0042] (2) Billet heating process: billet heating temperature 1200°C, holding time 2h;

[0043] (3) Controlled rolling process: the starting temperature of rough rolling is 1070°C, the rough rolling single-pass reduction ratios are 20.0%, 24.2%, 27.9%, 29.9%, 30.0% and 29.8%, respectively, and the rough rolling cumulative reduction The final rolling temperature of rough rolling is 1014℃; the starting tem...

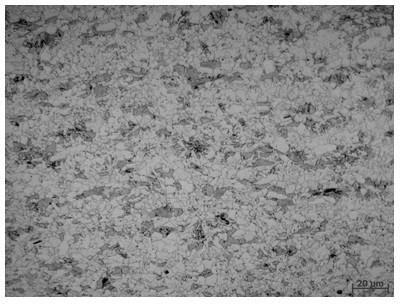

Embodiment 2

[0048]The thickness of the low-yield-ratio high-strength weathering steel in this example is 6 mm, and its chemical composition and mass percentage are shown in Table 1.

[0049] The production method of the high-strength weathering steel with low yield ratio in this embodiment includes smelting, continuous casting, slab heating, controlled rolling, and controlled cooling. The specific process steps are as follows:

[0050] (1) Smelting and continuous casting process: After smelting, the molten steel is continuously cast into a slab, and the thickness of the slab is 150mm;

[0051] (2) Billet heating process: billet heating temperature 1250°C, holding time 2h;

[0052] (3) Controlled rolling process: the starting temperature of rough rolling is 1150°C, the rough rolling single-pass reduction rates are 20.0%, 23.3%, 27.2%, 28.4%, 29.2% and 29.4%, respectively, and the rough rolling cumulative reduction The final rolling temperature of rough rolling is 1088℃; the starting tempe...

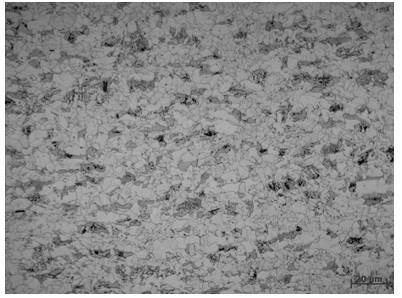

Embodiment 3

[0057] The thickness of the low-yield-ratio high-strength weathering steel in this example is 12 mm, and its chemical composition and mass percentage are shown in Table 1.

[0058] The production method of the high-strength weathering steel with low yield ratio in this embodiment includes smelting, continuous casting, slab heating, controlled rolling, and controlled cooling. The specific process steps are as follows:

[0059] (1) Smelting and continuous casting process: After smelting, the molten steel is continuously cast into a slab, and the thickness of the slab is 150mm;

[0060] (2) Billet heating process: billet heating temperature 1200°C, holding time 1h;

[0061] (3) Controlled rolling process: the starting temperature of rough rolling is 1050°C, the rough rolling single-pass reduction rates are 20.0%, 23.3%, 27.2%, 28.4%, 29.2% and 29.4%, respectively, and the rough rolling cumulative reduction Ratio of 84.0%, rough rolling finish rolling temperature 993°C; finish ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com