Modified high-nickel positive electrode material coated with fast ion conductor and preparation method of modified high-nickel positive electrode material

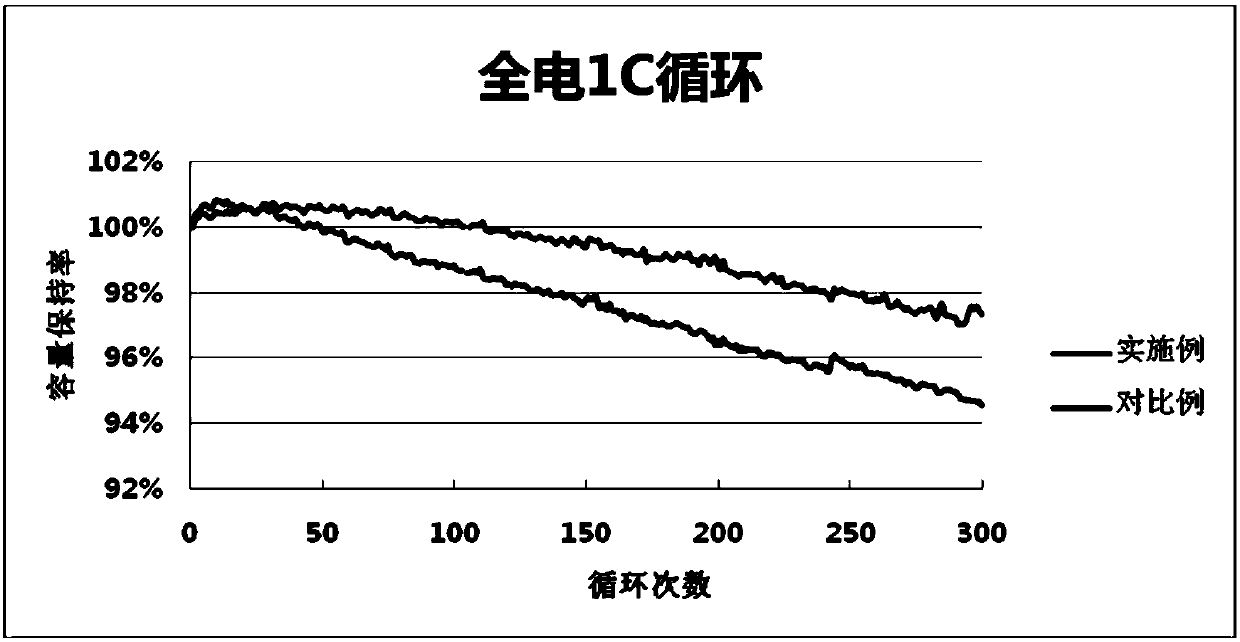

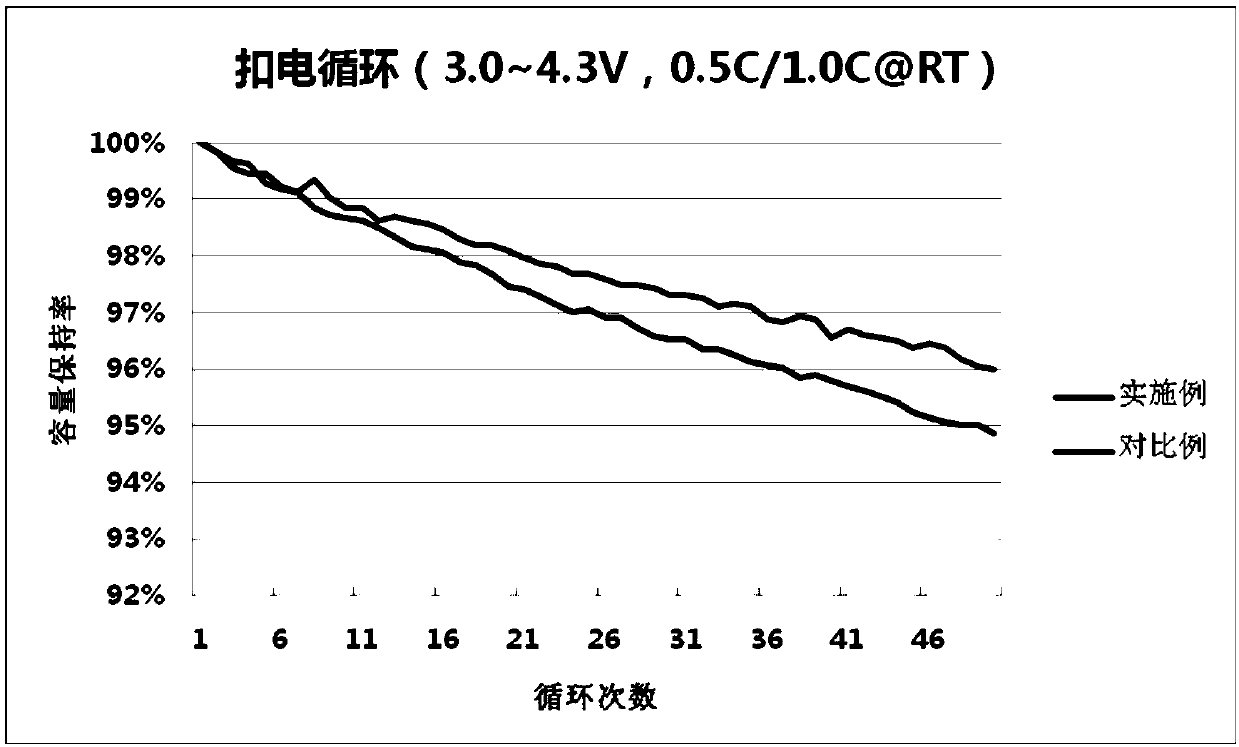

A positive electrode material and ion conductor technology, which is applied in the field of fast ion conductor-coated modified high-nickel positive electrode materials and its preparation, can solve the problems of high irreversible capacity, lithium-nickel mixed discharge, and high residual lithium in materials to improve high temperature stability and safety, increased long cycle life, and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

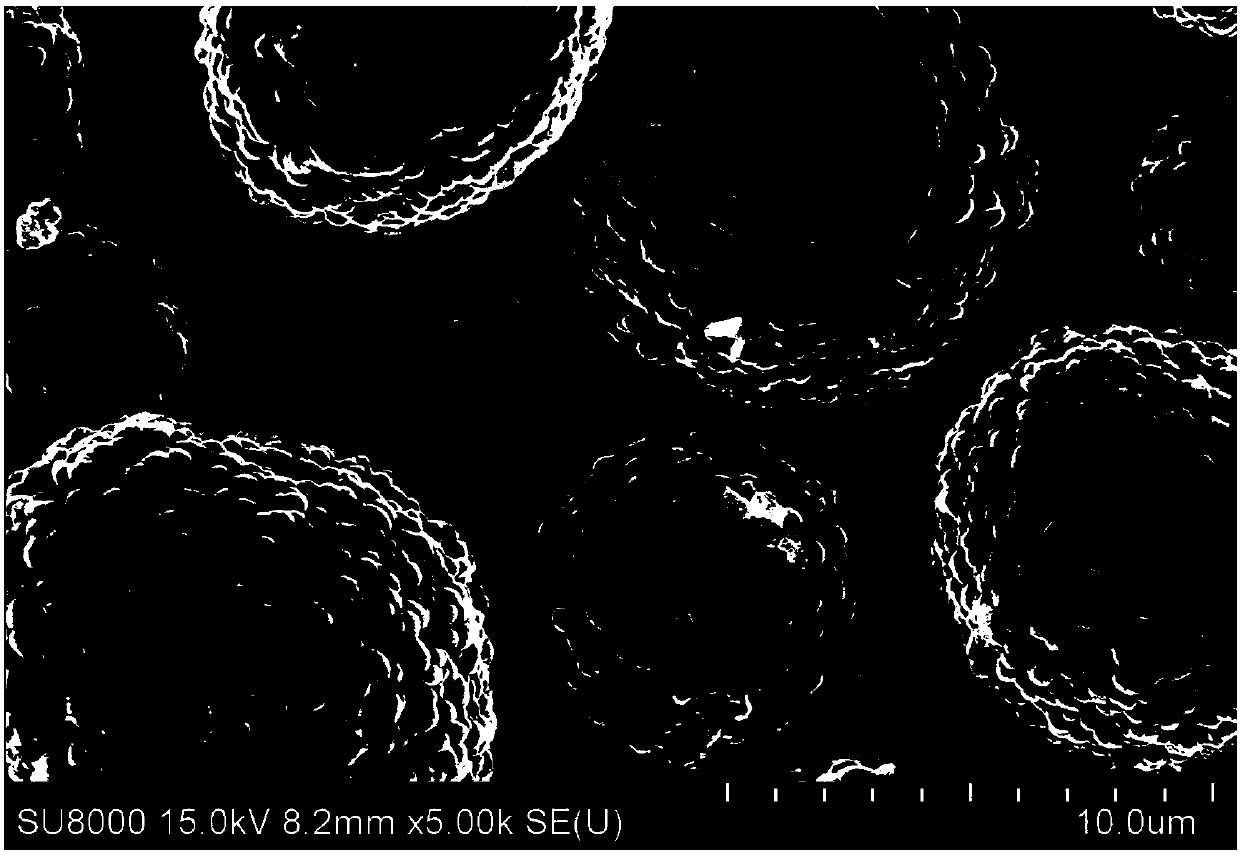

Embodiment 1

[0069] (1) Nickel sulfate, cobalt sulfate, manganese sulfate are dissolved in the ratio of 8:1:1 by Ni, Co, Mn element molar ratio in deionized water and are prepared into the salt solution that metal cation total concentration is 1.5mol / L, stir Make it fully mixed to obtain a mixed salt solution;

[0070] (2) Prepare 5.5 mol / L sodium hydroxide solution and 5 mol / L ammonia solution respectively, then add mixed salt solution, sodium hydroxide solution and ammonia solution into the reaction kettle in parallel, at 50°C, 200r Continuous co-precipitation reaction is carried out under the stirring condition of 1 / min. During the precipitation process, the ammonia value is controlled to 15g / L, and the pH=11.0. When the D50 of the precursor in the supernatant reaches 11±1.0, it overflows into the aging tank for aging The aging is carried out under stirring conditions, the stirring speed is 200rpm, and the aging time is 2h; after aging, the solid product is washed with a sodium hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com