Patents

Literature

34results about How to "Control the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of rice noodles

ActiveCN103005299AControl the production processThe production process is easy to controlFood preparationRice flourAlpha-amylase

The invention discloses a preparation method of rice noodles. The preparation method comprises the steps of fermenting a raw material, resisting aging, grinding into pulp and steaming and further comprises the step of resisting aging secondarily after the steaming step, wherein the step of resisting aging secondarily comprises the substeps of contacting amylase with a rice slice obtained in the steaming step and putting aside the rice slice for 20-80 minutes at 30-80 DEG C; the amylase is alpha-amylase and / or beta-amylase; and the raw material is rice and / or unpolished rice. By the preparation method, the production process can be conveniently controlled, the rice noodles can be produced on a large scale, and the produced rice noodles are stable in quality and long in shelf life.

Owner:湖南金健米制食品有限公司

Method for preparing waterborne polyurethane dispersion

InactiveCN101724135AImprove temperature resistanceImprove water resistancePolyurethane dispersionAlcohol

The invention discloses a method for preparing a waterborne polyurethane dispersion. The method comprises the following steps of: a, mixing polyhydric alcohol and an organic solvent of ketone and an anionic hydrophilic chain extender by stirring, adding isomerized diphenylmethane diisocyanate with stirring so as to perform complete reactions in the system to form a pre-polymer of blocked isocyanate; and b, after cooling, adding a anionic hydrophilic polyurethane salt forming agent into the pre-polymer, stirring the mixture to make the pre-polymer form the salt, adding the deionized water to emulsify the pre-polymer, adding the amine or alcohol chain extender with secondary chain extension to the pre-polymer and stirring, and after the reaction is finished, performing heating, decompression and removal of the organic solvent of ketone to obtain the waterborne polyurethane dispersion finally. The method for preparing the waterborne polyurethane dispersion is simple, and the prepared waterborne polyurethane dispersion has the advantages of high bonding strength and high hardness and has low cost and a good development prospect.

Owner:BEIJING COMENS NEW MATERIALS

Method for manufacturing high-precision NTC thermistor chip

ActiveCN106699158AInhibition of decompositionThe production process is easy to controlNegative temperature coefficient thermistorsBriquetteDecomposition

The invention discloses a method for manufacturing a high-precision NTC thermistor chip. The method comprises a step 1) of weighing corresponding metal oxides according to a chemical formula Mn3-x-y-zNixFeyCozQtO4, performing mixing ball-milling, low-temperature calcination, ball-milling crushing and high-temperature calcination, and obtaining thermal sensitive ceramic powder; a step 2) of performing ball-milling on the thermal sensitive ceramic powder, adding an organic binder, and performing drying, pelleting and sieving to obtain formed powder; a step 3) of performing dry pressing and isostatic pressing on the formed powder, and obtaining formed briquette; a step 4) of adding the formed briquette into an atmosphere furnace, performing sintering in the weak oxidizing atmosphere, and obtaining agglomerate; a step 5) of cutting the agglomerate into slices, coating the slices with silver or gold electrodes, performing heat treatment, cutting the slices into required sizes, and obtaining the high-precision NTC thermistor chip. The decomposition of FeMnNiO4 is restrained by controlling oxygen partial pressure in the sintering process, ingredient segregation is reduced by introducing low-temperature calcination before presintering, the production process is controlled easily, the chip resistance and B value pass rate are high, and the reliability is high.

Owner:GUANGZHOU MAGNET ELECTRICITY

Method for measuring thickness of galvanized layer

InactiveCN103453861AImprove thickness measurement accuracyImprove measurement accuracyUsing wave/particle radiation meansUltimate tensile strengthElectron

The invention provides a method for measuring the thickness of a galvanized layer. A galvanized sheet sample is placed in a coating machine, and a carbon rod is used for spraying the surface of the sample with carbon. The sample is placed in an electronic probe sample chamber which is vacuumized, a backscattered electron image of the sample is observed, the thickness of the galvanized layer takes account for 1 / 2 of the scanned area, the line scanning is adopted from the position far away from the outer layer of the galvanized layer by 1 / 2 of the thickness of the galvanized layer to the position, perpendicular to the galvanized layer, far away from the other layer of the galvanized layer by 1 / 2 of the thickness of the galvanized layer in the direction towards a base body to obtain a component analytic curve, 50% of the maximum strength of the steep side of the measured curve serves as the two boundary points of the galvanized layer, and the thickness of the galvanized layer is measured. Different areas are selected and the average value of a plurality of points is worked out, wherein the average value is the thickness of the galvanized layer. The thickness of the galvanized layer is measured through the component analytic curve of the sample, the boundaries are clear, the error problems caused by the fact that the surface of the sample is rough, the shape of the sample is complex, and the contrast of the sample is not obvious can be effectively solved, and the accuracy of measuring the thickness of the galvanized sheet galvanized layer is improved.

Owner:ANGANG STEEL CO LTD

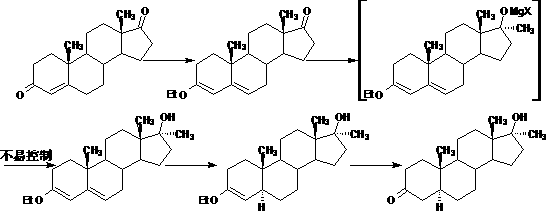

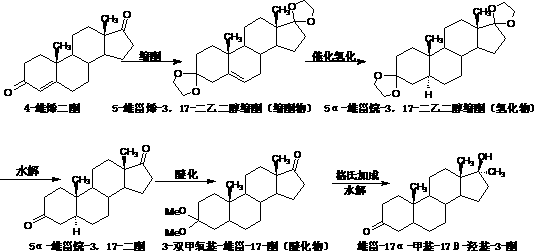

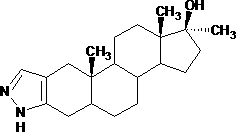

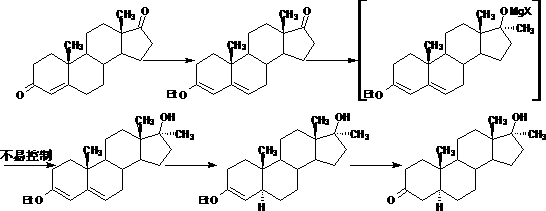

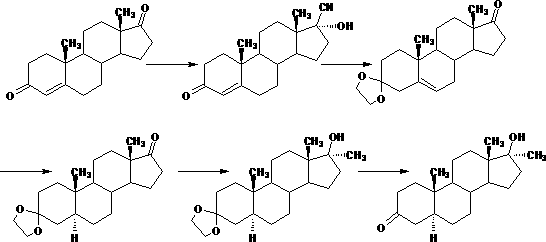

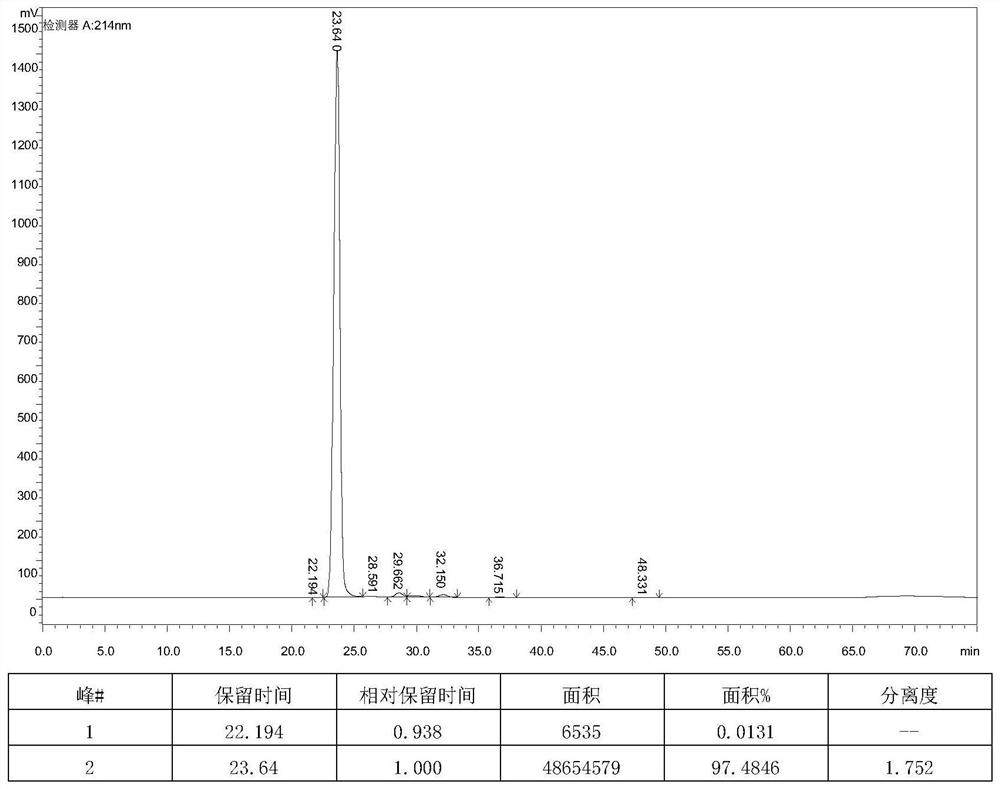

Method for synthesizing stanozolol intermediate androstane-17alpha-methyl-17beta-hydroxyl-3-ketone

PendingCN109438538AAvoiding the discharge and treatment of highly toxic wastewater is difficult to meet the standardsShort routeSteroidsAndrostaneKetone

The invention provides a method for synthesizing a stanozolol intermediate androstane-17alpha-methyl-17beta-hydroxyl-3-ketone. The method comprises the following steps: taking 4-androstenedione as a raw material, carrying out 3-site and 17-site keto-double-ketal, 5-site ethylenic bond catalytic hydrogenation and 3-site and 17-site double-ketal hydrolysis to prepare a compound 5alpha-androstane-3,17-diketone; then carrying out 3-site keto-double-etherification and 17-site Grignard addition, and finally carrying out hydrolysis to prepare the compound androstane-17alpha-methyl-17beta-hydroxyl-3-ketone, wherein the HPLC (High Performance Liquid Chromatography) purity of the compound is 99.0% or greater. The method provided by the invention is short in route, easy in production process control,environmentally-friendly, low in production cost and applicable to industrial large-scale production.

Owner:HUAZHONG PHARMA

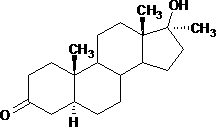

Preparation method of androstane-17alpha-methyl-17beta-hydroxy-3-ketone

The invention provides a preparation method of androstane-17alpha-methyl-17beta-hydroxy-3-ketone. According to the method, methyltestosterone as a raw material is subjected to ketalation, catalytic hydrogenation and a hydrolysis reaction to obtain the androstane-17alpha-methyl-17beta-hydroxy-3-ketone. The method has the advantages that the process is simple and clear, the production cost is low, the purity of the product is high, and the method is suitable for industrial production.

Owner:HUAZHONG PHARMA

Modified magnesium cement light wallboard

InactiveCN104761278AImproving quality is difficult to controlSound insulation effect is goodCeramicwarePerliteOxide

The invention provides a modified magnesium cement light wallboard. The modified magnesium cement light wallboard is composed of a foaming agent and the following components in parts by weight: 100 parts of magnesium oxide, 5-40 parts of fly ash and / or expanded perlite and polystyrene foam plastic light fillers, 60-80 parts of a sulfur-magnesium-phosphorus blending solution with the baume degree of 20-28 degrees, wherein the sulfur-magnesium-phosphorus blending solution is composed of the following components in parts by weight: 1 part of 50% sulfuric acid, 0.5 part of magnesium sulfate heptahydrate and 0.001 part of 50% phosphoric acid; and the volume ratio of the air bubble volume of the foaming agent to the total volume of the components is (4-5.8) to 1. According to the modified magnesium cement light wallboard, the sulfur-magnesium-phosphorus blending solution is used for replacing a magnesium chloride solution in the prior art, and magnesium chloride with strong activity and poor stability is removed; the technical problem that the quality of a magnesium cement wallboard is difficult to control is basically improved; and the defects, which are difficult to solve for a long period, that the magnesium cement wallboard has efflorscence halogenation and warping deformation, and corrodes a metal components, caused by chloridions are overcome.

Owner:张禹 +1

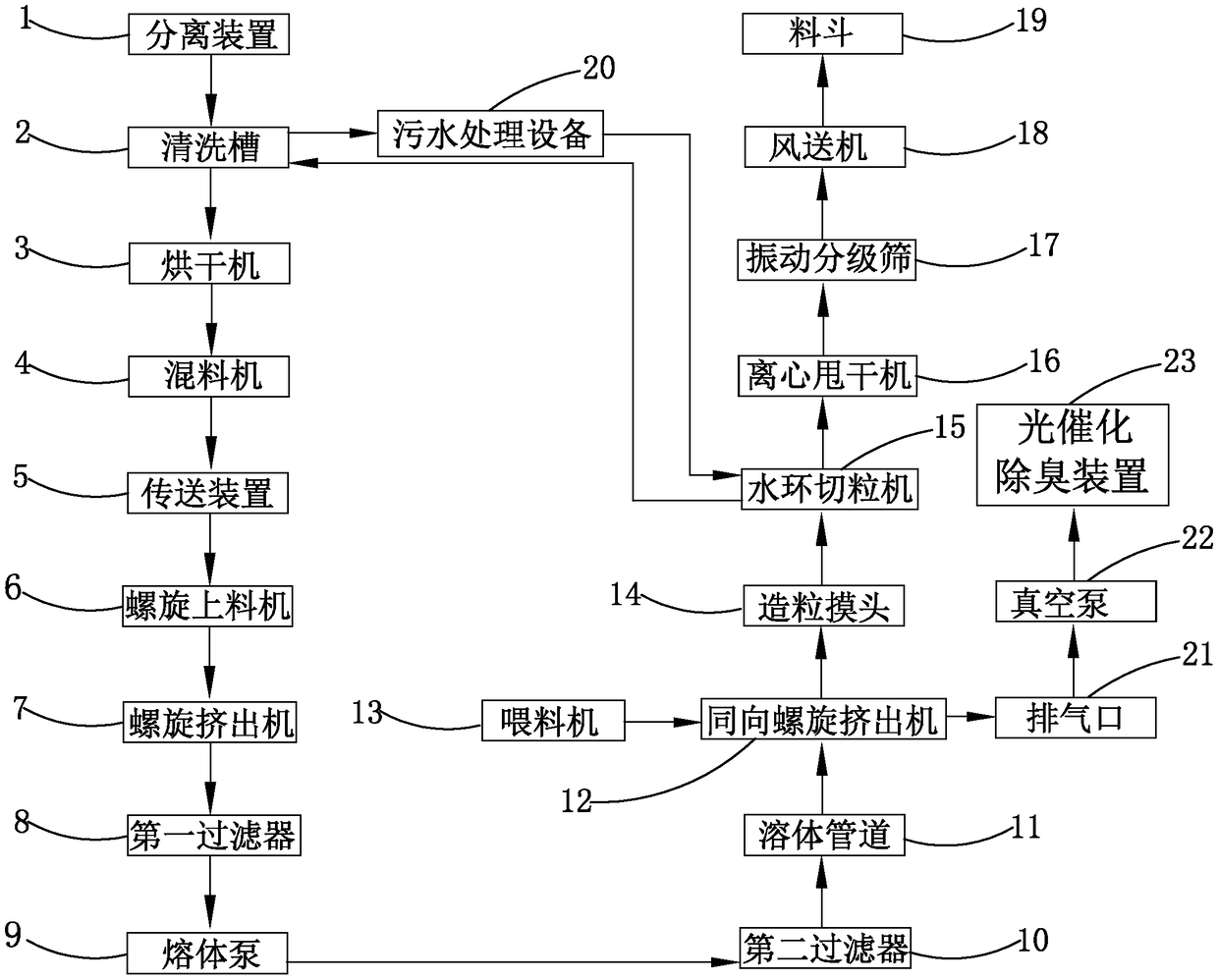

Plastic recycling unit

The invention provides a plastic recycling unit which comprises a separation device, a rinsing tank, a drying machine, a material mixing machine, a conveying device, a spiral feeding machine, a spiralextruding machine, a first filter, a melt pump, a second filter, a homodromous spiral extruding machine, a pelleting die head, a water ring pelletizer and a material receiving device, wherein a mainfeeding hole of the homodromous spiral extruding machine is connected with the second filter, and an auxiliary feeding hole of the homodromous spiral extruding machine is connected with a feeding machine; an air outlet is also formed in the spiral extruding machine and / or the homodromous spiral extruding machine; the air outlet is connected with a gas purification device; therinsing tank is also connected with waste water treatment equipment; a waste water outlet of the waste water treatment equipment is connected with the water ring pelletizer; and a water outlet of the water ring pelletizeris connected with a water inlet of the waste water treatment equipment by a pipeline. According to the plastic recycling unit provided by the invention, the technical problems in the prior art of being high in energy consumption in plastic recycling and large in amount of impurities and polluting the environment are solved.

Owner:深圳市华世纪联合企业管理有限公司

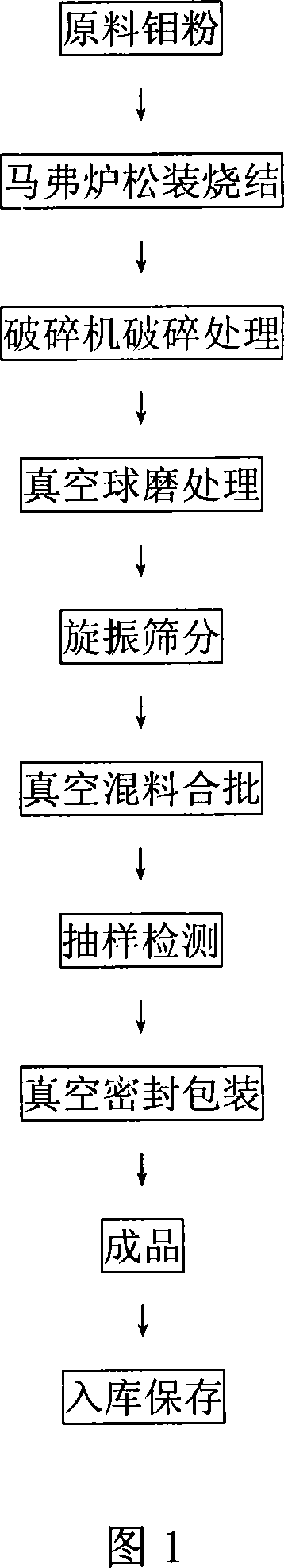

Preparing process of hypoxia large particle special molybdenum powder special for LCD

InactiveCN101199998AThe production process is easy to controlSimple and efficient operationLiquid-crystal displayLiquid crystal

Disclosed is a method that prepare LCD exclusive use special type molybdenum powder with low oxygen and large particle size, relating to a production method that use the method of hydrogen reduction sintering granulation to prepare low oxygen molybdenum powder with large particle size which is used for liquid crystal television and LCD. The invention is characterized in that the preparation process is to carry out granulation sintering in the molybdenum powder hydrogen reduction situation, and to crush in protective atmosphere, execute ball milling in vacuum; screen and classify the molybdenum powder after ball milling, then the LCD sputtering target material, exclusive use, low oxygen, large particle size, special type molybdenum powder is obtained. The method of the invention is to use hydrogen reduction sintering granulation and the subsequent ball milling treatment to prepare molybdenum powder which can meet the requirements of LCD sputtering target material; the device in using has simple structure and can make continuous and mass production with short preparation process; the technique is easy to control, the invention has low requirements for raw material molybdenum powder, the performance of product can meet the requirements of the preparation of sputtering target material.

Owner:JINDUICHENG MOLYBDENUM CO LTD

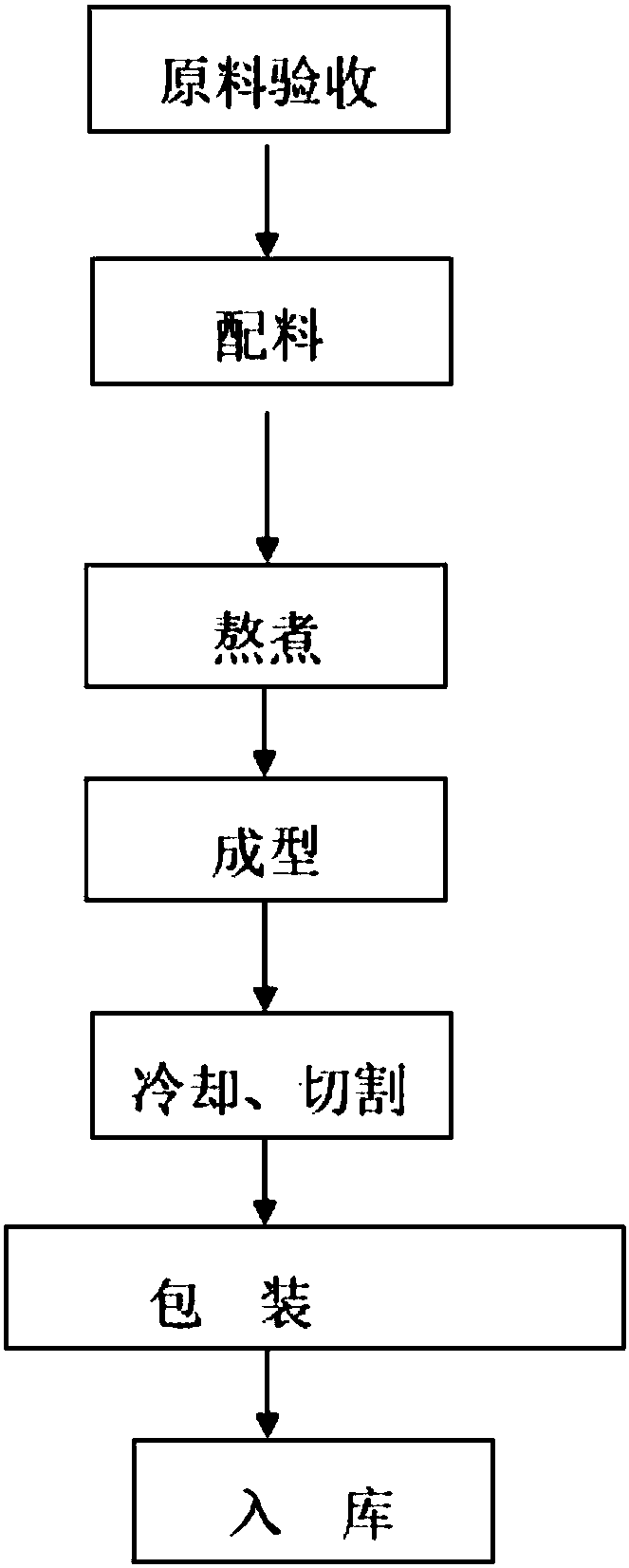

Dried jujube cakes and making technology thereof

InactiveCN107647358AReduce the growth of bacteriaProduction safetyConfectionerySweetmeatsCorn starchZiziphus jujuba

The invention discloses dried jujube cakes and a making technology thereof. The dried jujube cakes comprise 10-20 parts of walnut kernels, 2-3 parts of maltose, 3-5 parts of white granulated sugar, 10-15 parts of heart-shaped jujubes, and 50-70 parts of corn starch. The making technology comprises the following making steps of checking and accepting the purchased walnut kernels, the purchased maltose, the purchased white granulated sugar, the purchased heart-shaped jujubes, the purchased corn starch, and auxiliary materials according to a raw material acceptance criteria, demanding an effective quality and hygienic detection report for a supplier, wherein if various indexes in the report conform to the criteria, the materials are acceptable, or else, the materials are rejected, and preparing 10-20 parts of the walnut kernels, 2-3 parts of the maltose, 3-5 parts of the white granulated sugar, 10-15 parts of the heart-shaped jujubes, and 50-70 parts of the corn starch. According to the dried jujube cakes and the making technology thereof disclosed by the invention, the raw materials of the dried jujube cakes can be controlled, the production process can be standardized, the breedingquantity of bacteria in the dried jujube cakes in the production process and the packing process can be reduced, the safety production can be realized, and the product quality of the dried jujube cakes can be improved.

Owner:福建一品居食品有限公司

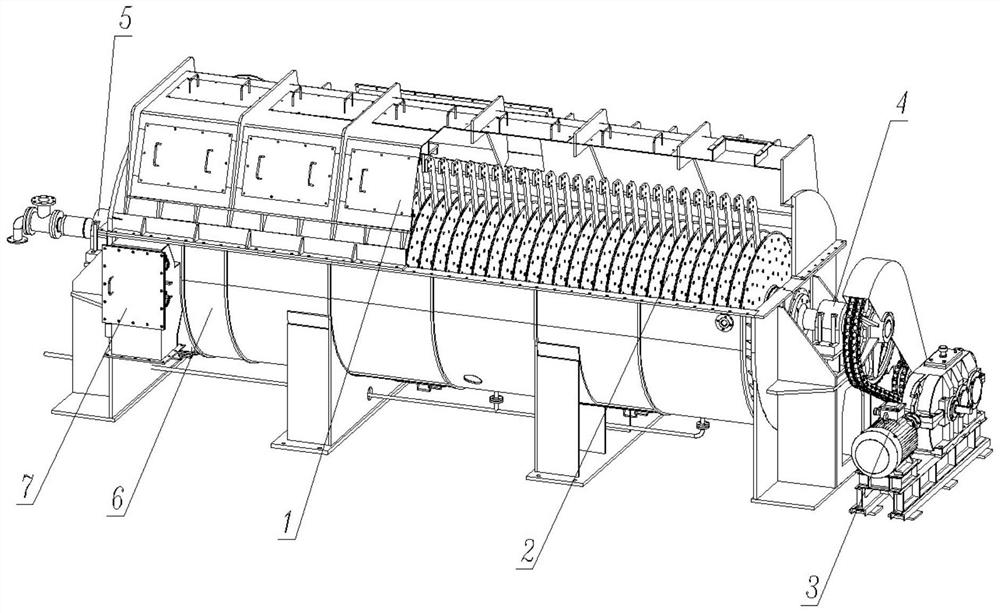

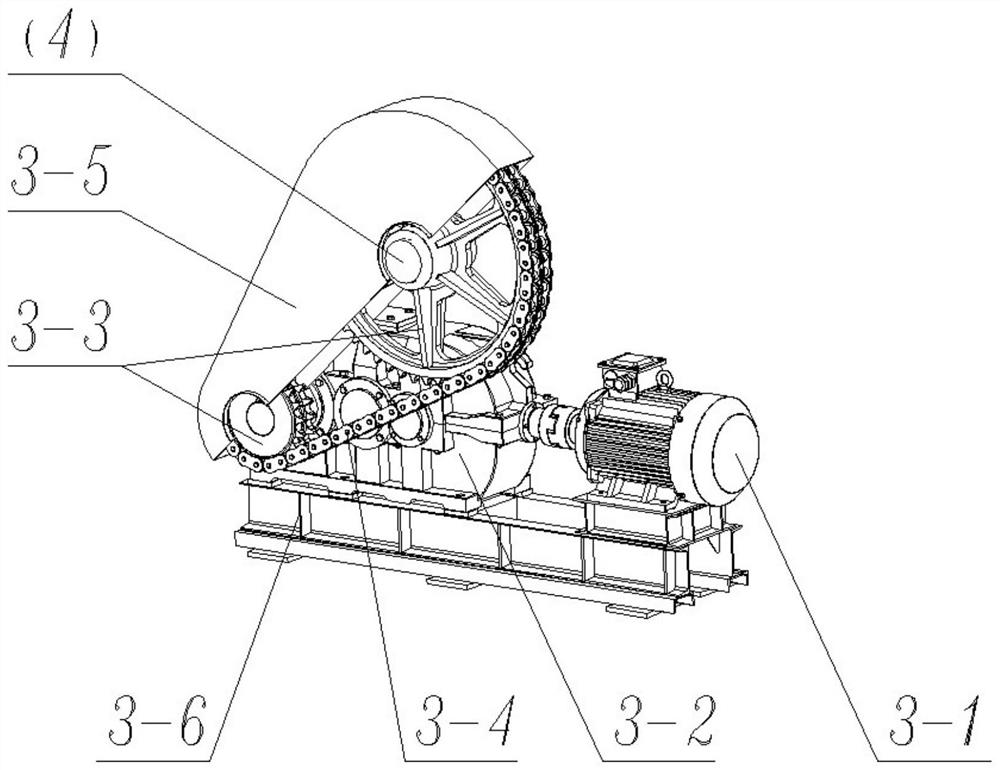

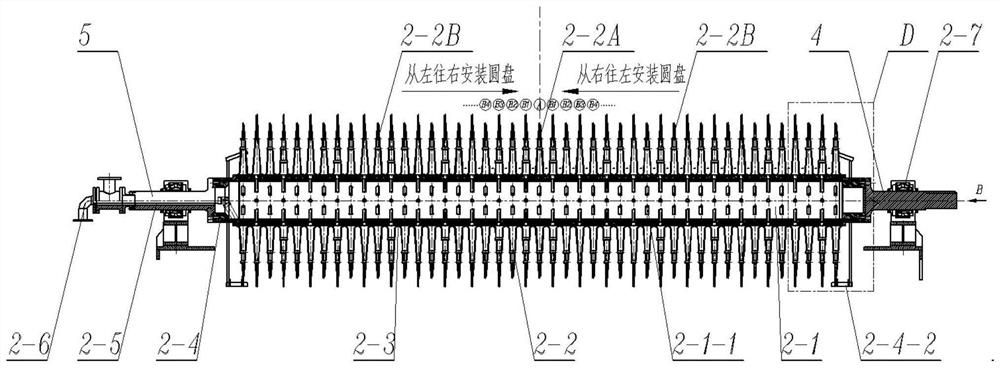

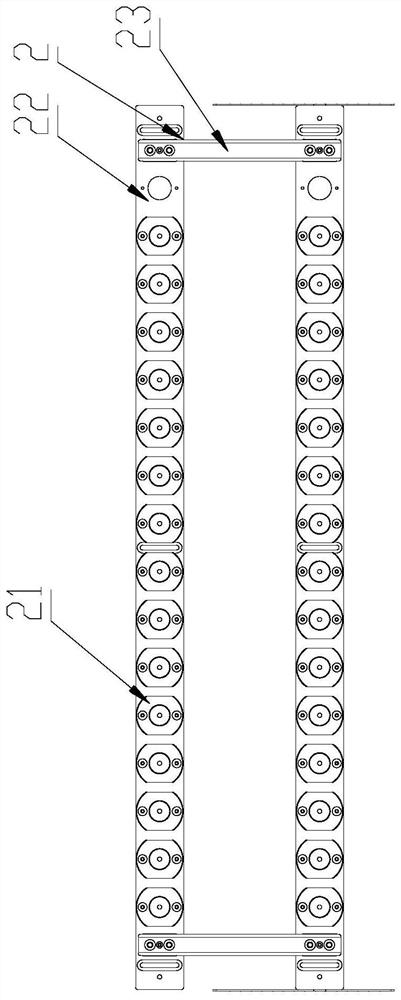

Split type disc sludge drying machine

PendingCN113402147ASmall footprintReduce shipping costsSludge treatment by de-watering/drying/thickeningDispersed particle separationCircular discSludge

The invention provides a split type disc sludge drying machine, which comprises a split type shell, a split type hollow shaft system, a driving device system and a discharging device, wherein the split type shell and a foundation are fixedly installed, the split type hollow shaft system is mounted in the split type shell, the driving device system is arranged on the driving side of the split type shell and connected with the hollow main shaft of the split type hollow shaft system to drive the hollow main shaft to rotate, the other side of the split type shell is a steam inlet side, the discharging device is installed on the split type shell and is close to the steam inlet side, the split type hollow shaft system comprises the hollow main shaft, a plurality of detachable discs, a siphon elbow and a rotary joint, the interior of the hollow main shaft is of a cavity structure, guide pipes for steam and condensate water to flow in and out of the disc cavity are distributed on the hollow main shaft, the discs are detachably mounted on the hollow main shaft at equal intervals, the cavities of the discs are communicated with the hollow main shaft, the siphon elbow is mounted on the steam inlet side, the siphon elbow is connected with the rotary joint, and the other end of the rotary joint extends into the hollow main shaft.

Owner:杭州江河机电装备工程有限公司

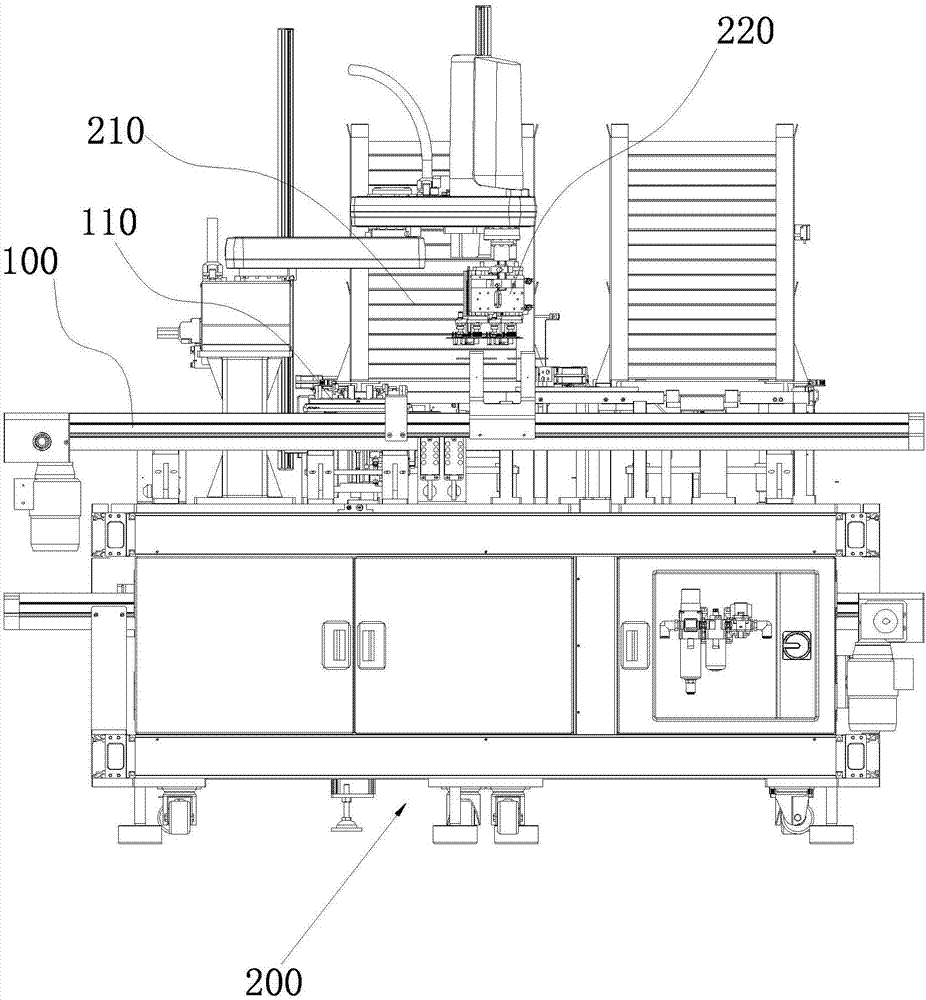

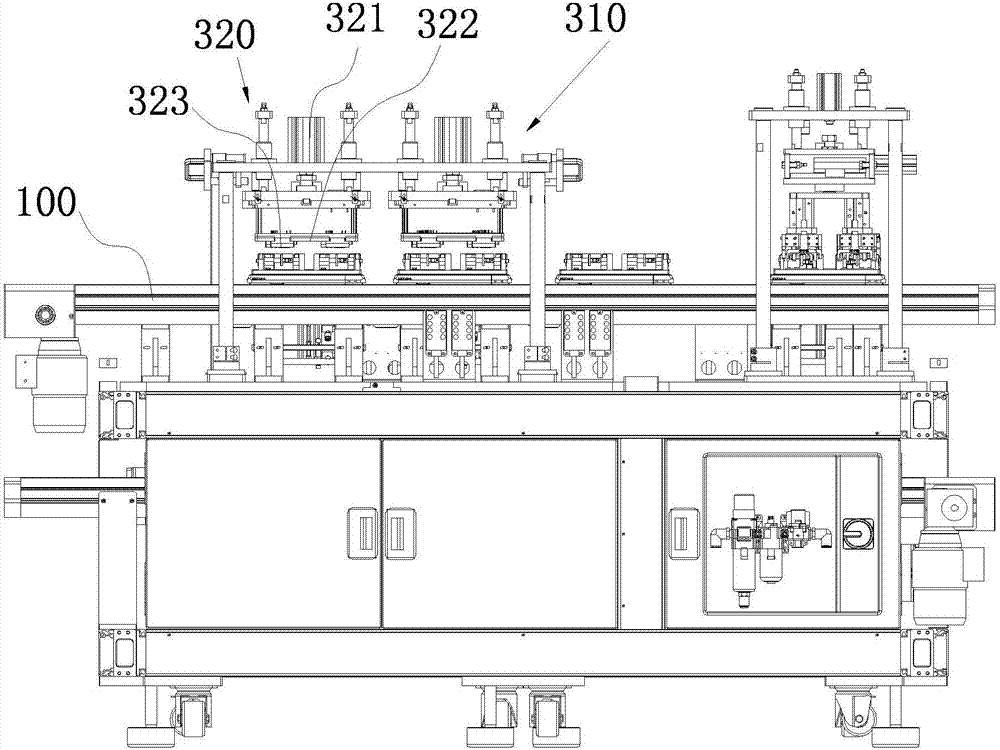

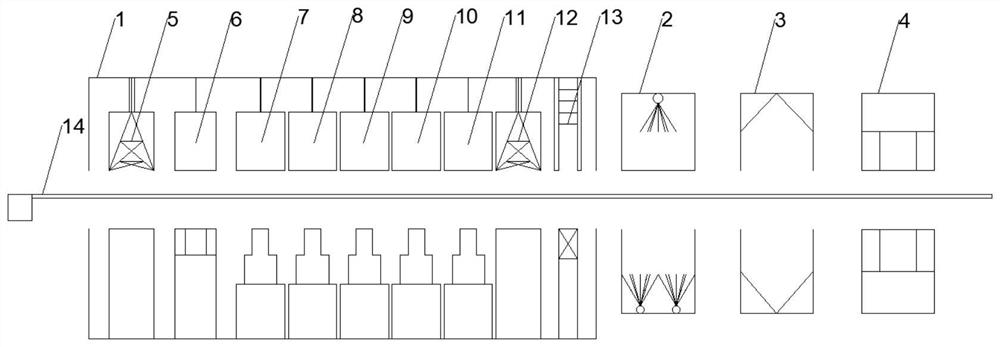

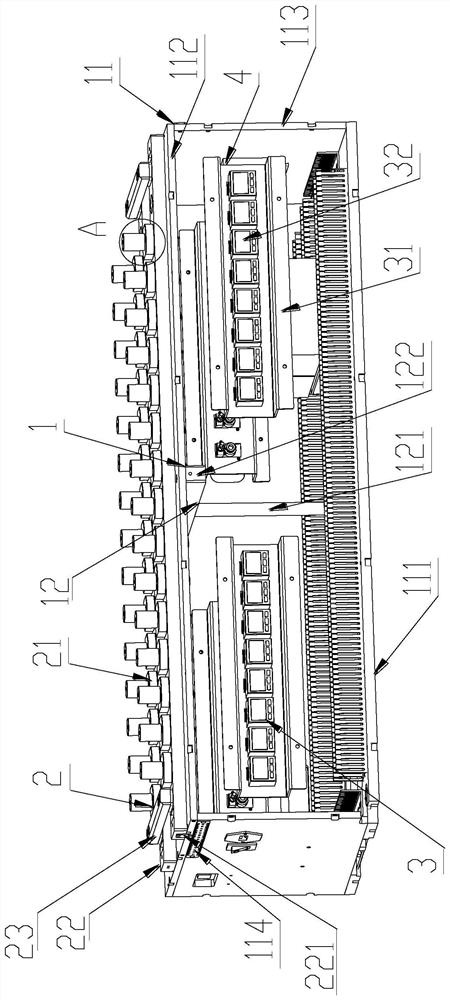

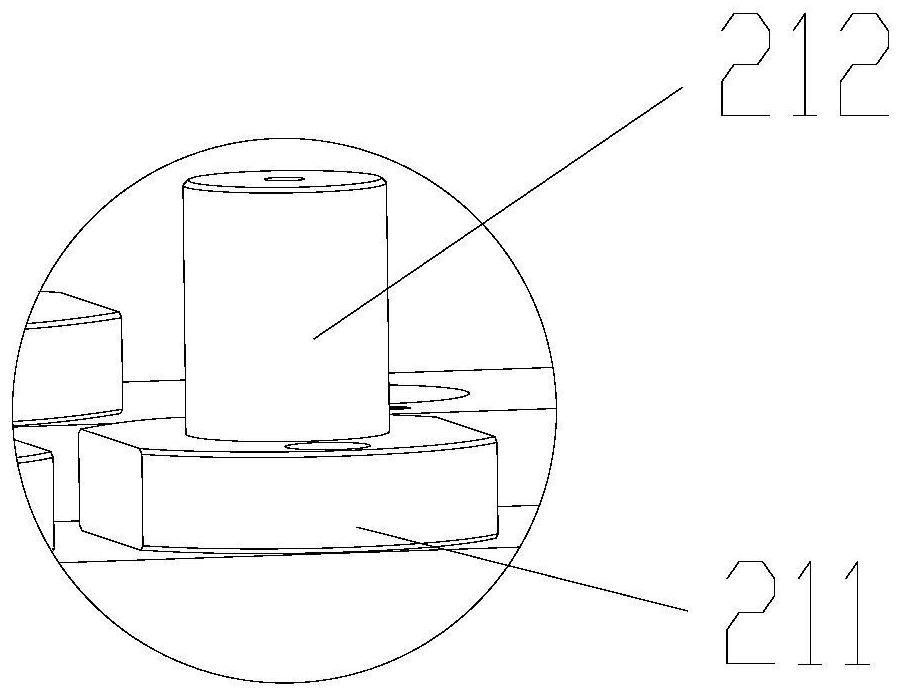

Automated carrier module production line

PendingCN107958588AImprove assembly accuracyImprove efficiencyElectric signal transmission systemsProduction lineProcess engineering

The invention provides an automated carrier module production line. The automated carrier module production line is characterized in that a base feeding mechanism comprises a first tray, a first robotand a streamline carrier, a plurality of bases are put on the first tray, and the first robot is used for transferring the bases onto the streamline carrier; a PCB (printed circuit board) feeding mechanism is connected with the base feeding mechanism and comprises a second tray and a second robot, a plurality of PCBs are put on the second tray, and the second robot is used for transferring the PCBs onto the bases; an upper cover assembling mechanism is connected with the PCB feeding mechanism and comprises a third tray, a third robot and a cover plate press-fit module, a plurality of upper covers are put on the third tray, the third robot is used for clamping the upper covers and then putting the same on the bases of the streamline carrier, and the cover plate press-fit module is used forassembling the upper covers on the bases. The automated carrier module production line can automatically assemble carrier modules and is high in assembling accuracy and efficiency, and production efficiency is improved greatly.

Owner:宁波德晶元科技有限公司

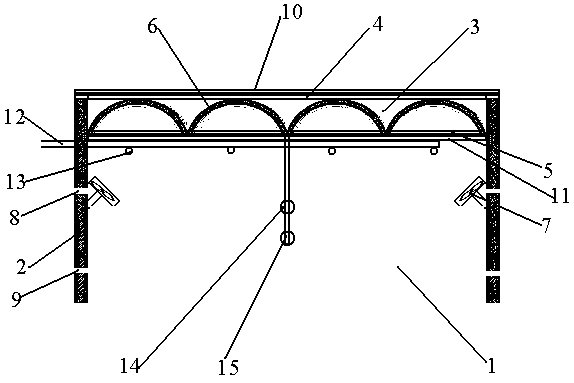

Morchella greenhouse planting method

InactiveCN110495346APrevent degradationStable temperature and humidityCultivating equipmentsMushroom cultivationThree levelDisease

The invention relates to a morchella greenhouse planting method, and belongs to the technical field of edible fungus cultivation. The method comprises the steps that a heat-insulating and soaking typemorchella planting greenhouse is constructed, three levels of bacteria, namely, mother species, original species and cultivated species are prepared, a nutrition bag is prepared, sowing is conducted,and field management is conducted in three stages. The method has the advantage that the greenhouse adopts a special roof and a gas exchange system, the temperature and humidity in the greenhouse canbe kept stable, and the temperature and the humidity of all positions are balanced; breeding in three levels can effectively preventing strain degeneration, the disease resistance is increased, the fruiting rate is increased, the nutrition bag is adopted, the three-level field management is combined, the production process can be effectively controlled, the yield can be increased, and the fruiting quality can be improved.

Owner:重庆玖旺食品有限公司

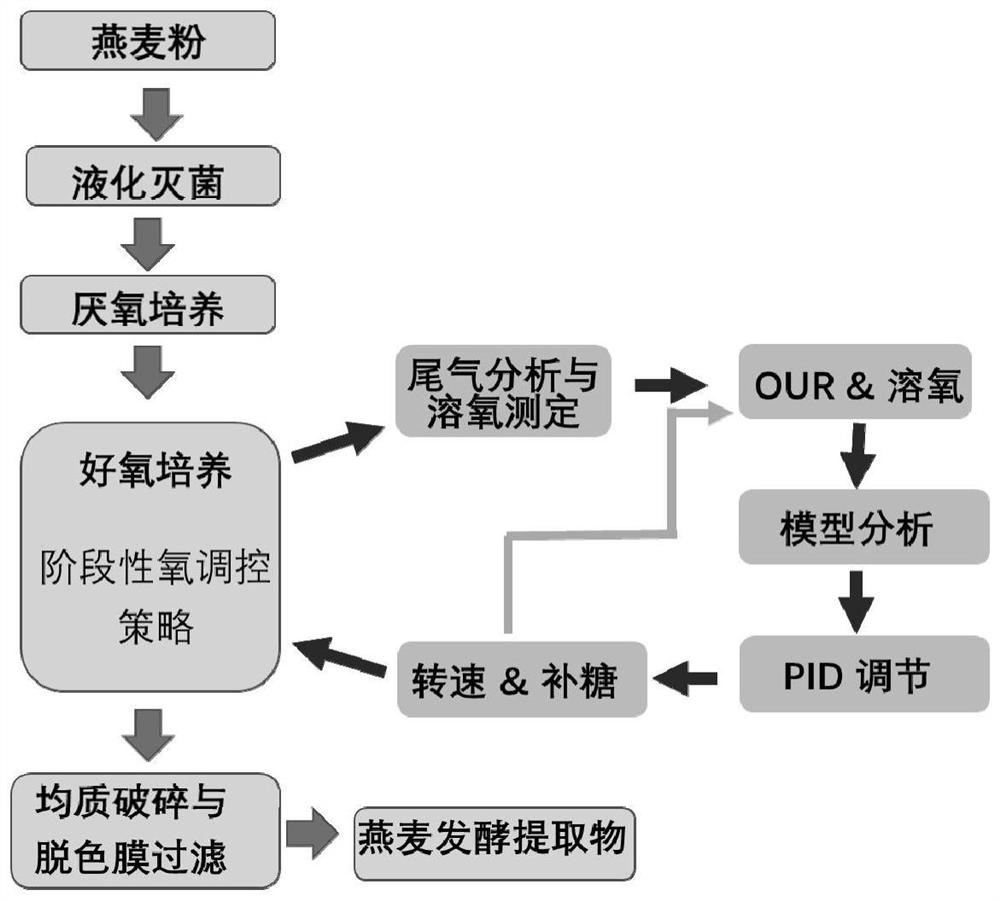

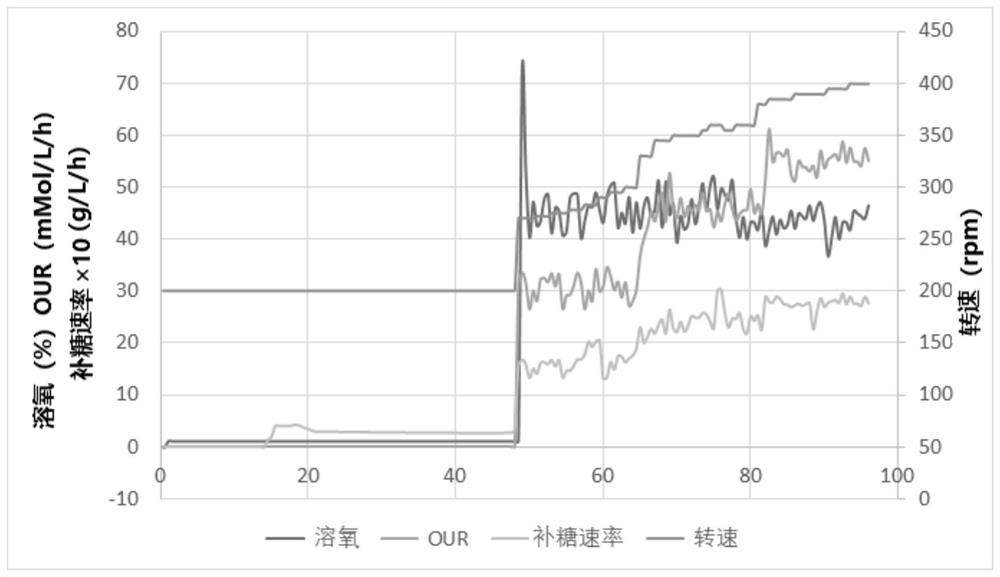

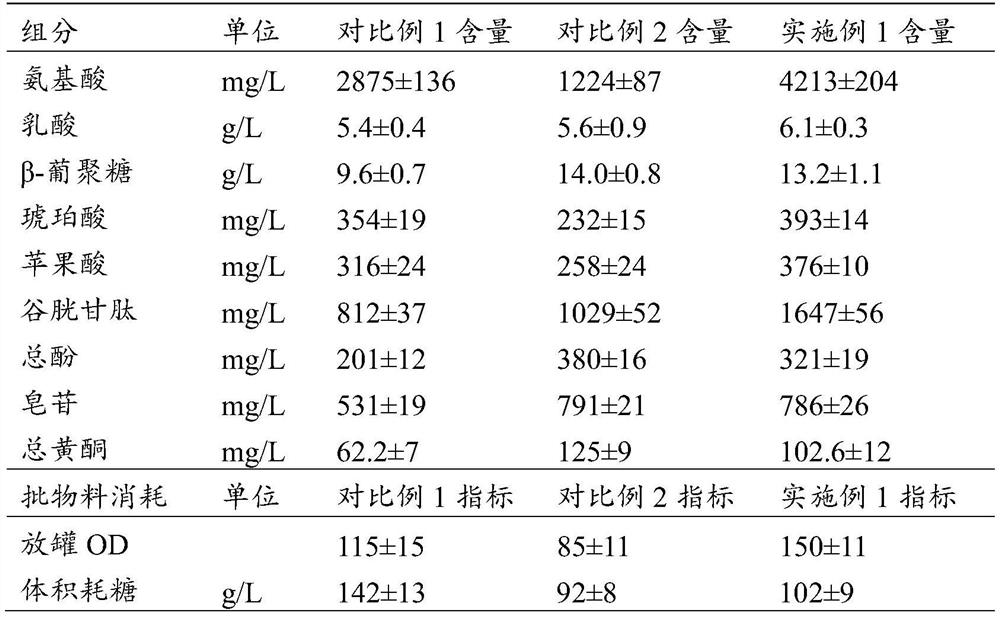

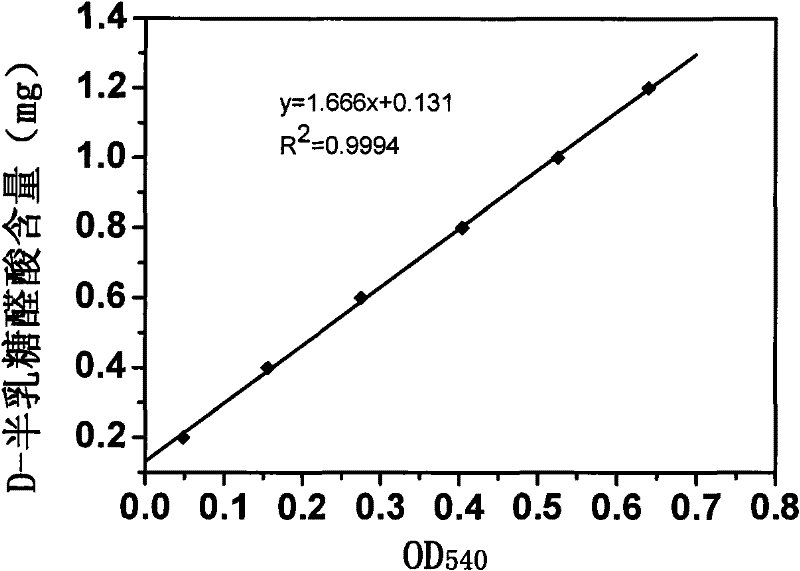

Accurate control method for preparation process of oat fermentation extract

ActiveCN113509427APrecisely control the production processControl the production processCosmetic preparationsToilet preparationsBiotechnologySaccharomyces

The invention provides an accurate control method for an oat fermentation extract preparation process, and the method comprises the following steps: sequentially carrying out anaerobic fermentation and aerobic fermentation on oat, controlling dissolved oxygen in the aerobic fermentation process to be not less than 45%, and controlling the aerobic fermentation process by controlling the oxygen consumption rate, specifically including the following steps: controlling the oxygen consumption rate at 30 + / -2.1 mmol / L / h in the first stage of aerobic fermentation, controlling the oxygen consumption rate at 45 + / -2.2 mmol / L / h in the second stage of aerobic fermentation, and controlling the oxygen consumption rate at 55 + / -2.5 mmol / L / h in the third stage of aerobic fermentation. According to the precise control method for the preparation process of the oat fermentation extract, provided by the invention, in an aerobic process of sequentially fermenting by utilizing bifidobacterium and saccharomycetes, the process is controlled through an optimized oxygen consumption rate level and an optimized dissolved oxygen level; the oat extract with the content of various active ingredients such as glutathione, amino acid and flavone remarkably increased is prepared, and the production process of the oat fermentation extract with the process capable of being accurately and effectively controlled is formed.

Owner:山东花物堂生物科技有限公司

Preparation method for acrylate-modified epoxy resin cathode electrophoresis emulsion

ActiveCN108912931AReduce the chance of aggregationImprove anti-corrosion performancePaints for electrolytic applicationsOrganic acidEmulsion

The invention discloses a preparation method for an acrylate-modified epoxy resin cathode electrophoresis emulsion. The method adopts a monoprotic organic acid containing a double bond and a biproticorganic acid containing a double bond or / and an acid anhydride to react with epoxy resin, double bonds are introduced into a main chain of the epoxy resin, acrylic resin is grafted into the epoxy resin by utilizing copolymerization of the double bonds and an acrylate monomer, more acrylic resin can be introduced onto the main chain of the epoxy resin, adjustment and control of an introduction amount of the acrylate monomer are achieved through control of the content of the double bonds, and a molecular weight of the main epoxy resin is adjusted through a ratio of carboxyl to epoxy groups; themain body of the prepared product is epoxy resin, so that good anticorrosive performance of a paint film is guaranteed; and when the epoxy resin is aminated, two different organic amines are added step by step for a reaction, so that the reaction process is milder. According to the method disclosed by the invention, the acrylate-modified epoxy resin emulsion prepared by the method has good performance of a paint film and good ultraviolet and salt spray resistance, and can be used for workpieces under conditions of exposure under the sun.

Owner:吴让君

A cleaning method for laser perforated aluminum nitride ceramic plate

ActiveCN110918548BAvoid damageAvoid corrosionDrying gas arrangementsCleaning using liquidsMegasonic cleaningMolten slag

The invention discloses a method for cleaning a laser perforated aluminum nitride ceramic plate. The perforated aluminum nitride ceramic plate is first soaked in acid, and the oxides in the molten slag react with the acid to bond the aluminum nitride ceramic plate. The slag is hollow and soft, and the slag on the surface of the ceramic plate can be removed by gently wiping with a cloth to reduce the damage to the ceramic plate caused by the scraper; multiple ultrasonic cleaning in the middle can make large pieces of soft slag fall off, which is convenient for acid and Inner layer slag reaction, adding block cleaning process to improve cleaning efficiency; short-term soaking with low-concentration alkali, the alkali reacts slightly with the surface of the aluminum nitride ceramic sheet, and the slag in the micropores can be completely cleaned to avoid alkali If the cleaning concentration is too high and the time is too long, it will cause corrosion pits and excessive roughness on the surface of aluminum nitride ceramics, so as to ensure that there is no residue of slag in the micropores; all ultrasonic cleaning is to put the aluminum nitride ceramic plate into absolute ethanol or Ultrasonic in isopropanol, the aluminum nitride plate has no reaction with absolute ethanol and isopropanol, and the production process is better controlled.

Owner:GUANGDONG GASTIGHT HERMETICAL COMPONENT

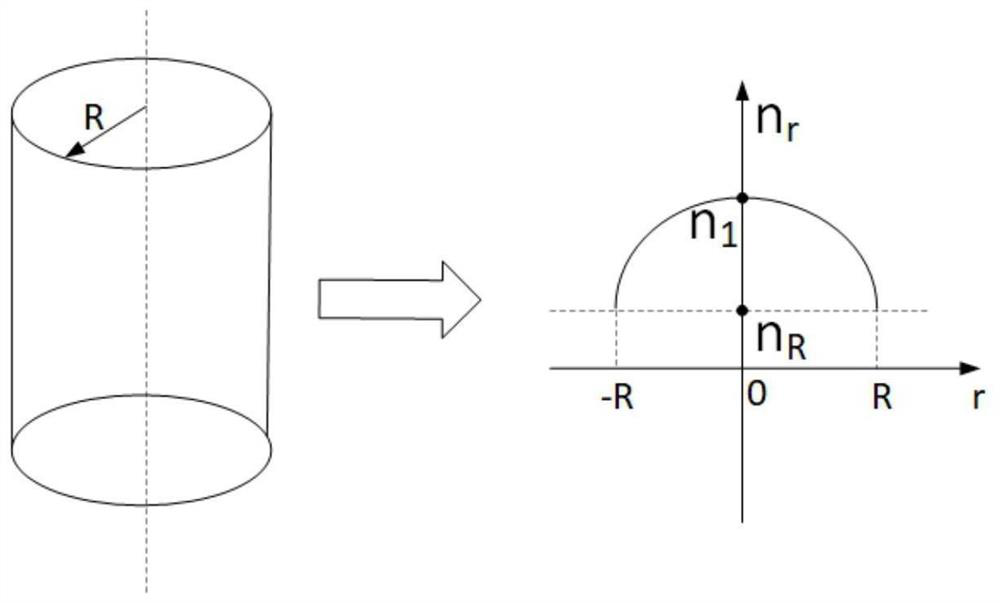

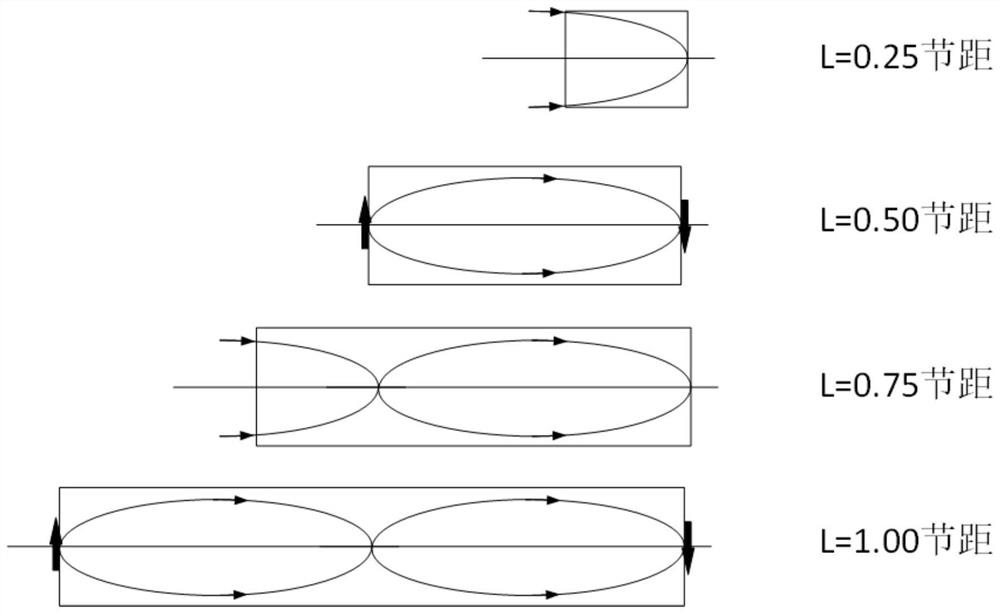

Preparation method of self-focusing lens

PendingCN113930731AControl the production processSimple processVacuum evaporation coatingSputtering coatingSputter depositionRefractive index

A preparation method of a self-focusing lens comprises the following steps: a first material with the refractive index of n1 is used for manufacturing a center material, the center material is made to rotate, the first material and a second material with the refractive index smaller than n1 are sputtered and deposited towards the center material simultaneously, and the sputtering and deposition rate of the first material and the sputtering deposition rate of the second material are respectively controlled, so that when the radius of the lens reaches the target radius R, the radial refractive index nr of the lens is as shown in the specification, so that the required cylindrical self-focusing lens of which the center refractive index is n1, the final radius is the target radius R and the radial edge refractive index is nR is formed. According to the preparation method, as the radius of the lens is gradually increased, the two materials with different refractive indexes are mixed and deposited according to different proportions by controlling the sputtering deposition rate, and therefore the refractive index of the self-focusing lens gradually changes in the radial direction; and the process is simple, and the lens manufacturing process can be easily controlled by controlling the sputtering and deposition rate.

Owner:东莞旭和光电科技有限公司

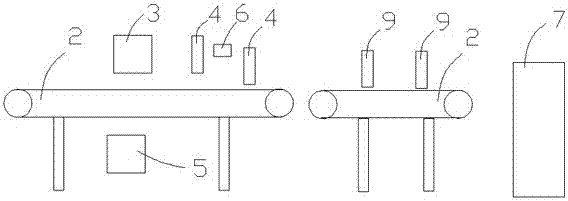

A production system and production method of energy-saving and environment-friendly fiber cement building materials

InactiveCN105034157BRealize intelligenceFully automatedFeeding arrangmentsAuxillary shaping apparatusMultiple sensorMaterials science

The invention relates to the technical field of fiber cement building materials and discloses a production system for an energy-saving environment-friendly fiber cement building material and a production method of the production system. The production system comprises a conveying platform used for conveying the fiber cement building material, a feeding device, scraping devices, forming devices and a controller. The conveying platform conveys the manufactured fiber cement building material. In the conveying direction of the conveying platform, the feeding device, the scraping devices and the forming devices are sequentially arranged above the conveying platform. The controller is in communication with the conveying platform, the feeding device, the scraping devices and / or the forming devices. Through the adoption of the production system and the production method, an existing fiber cement building material is covered with a functional material. All the devices of the production system are used in cooperation with the controller and corresponding devices through coordination control of the controller and the arrangement of multiple sensors to form the production system, and production intelligence and automation are achieved.

Owner:SINOMA ZHUZHOU HONGBO

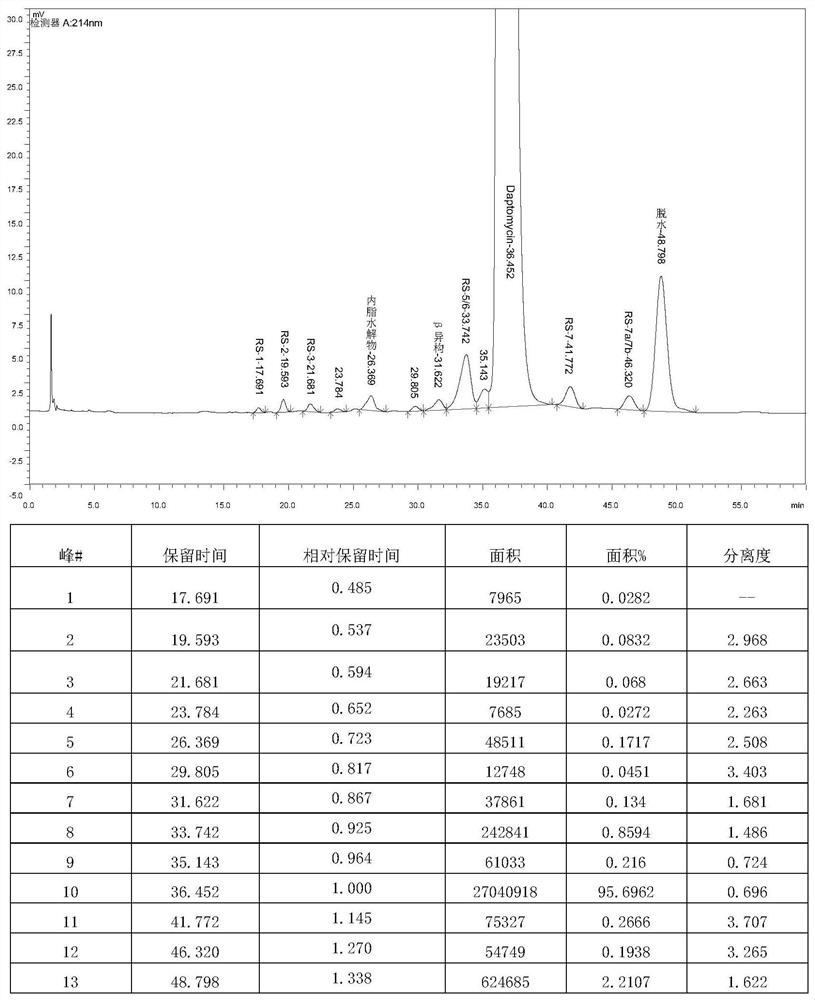

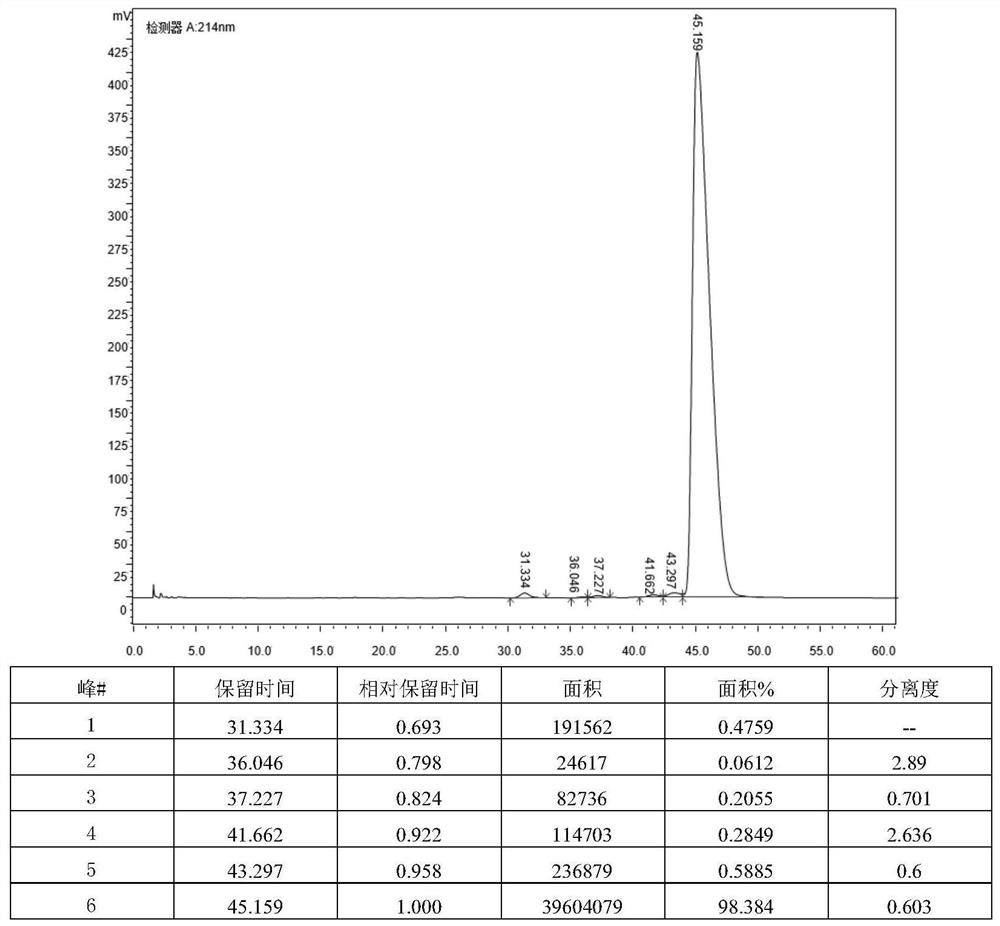

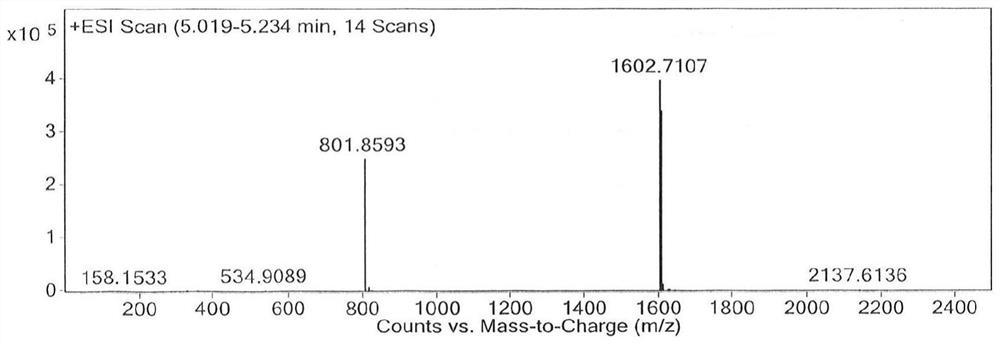

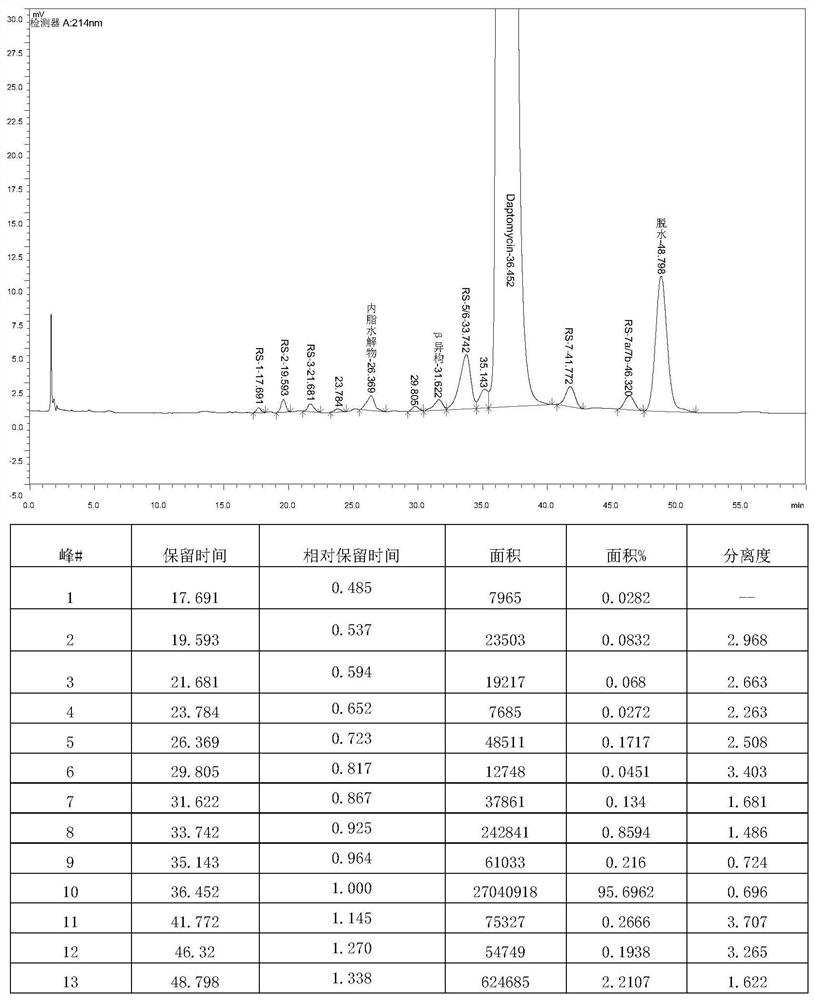

Method for preparing Daptomycin impurity RS-7a

PendingCN113929747AControl the production processImprove product qualityPeptide preparation methodsPharmaceutical drugAqueous solution

The invention belongs to the field of medicine preparation, and relates to a method for preparing a Daptomycin impurity RS-7a. The method specifically comprises the following steps of dissolving a Daptomycin sample with an acetonitrile-water solution, adding an acid solution for reaction to obtain a feed liquid containing the Daptomycin impurity RS-7a, and purifying by preparative chromatography to obtain a pure product of the Daptomycin impurity RS-7a. The method, which is provided by the invention, for preparing the Daptomycin impurity RS-7a, is simple and convenient in operation and low in cost, can be used for amplified preparation as required, and meets the requirements of research and production.

Owner:LUNAN PHARMA GROUP CORPORATION

Preparation method of crystal silicon wafer type capacitor

ActiveCN105225835AExcellent performanceLow heating temperatureFixed capacitor electrodesFixed capacitor dielectricThermal sprayingSemiconductor

The invention discloses a preparation method of a crystal silicon wafer type capacitor, which comprises the steps of coating the upper surface and the lower surface of a crystal silicon wafer with a resin paste containing metal powder; overlaying 80-120 crystal silicon wafers coated with the resin paste, drying the crystal silicon wafers at a temperature of 80-90 DEG C so as to acquire a capacitor precursor; and printing metal electrodes on the side surface of the capacitor precursor through a method of thermal spraying so as to acquire the crystal silicon wafer type capacitor. The preparation method has the advantages that the semiconductor performance of silicon crystal is excellent, the heating temperature of a base material is low in preparation of the capacitor, the construction time is short, and the preparation method is environment-friendly and pollution-free.

Owner:SHANGHAI JINPEI ELECTRONICS

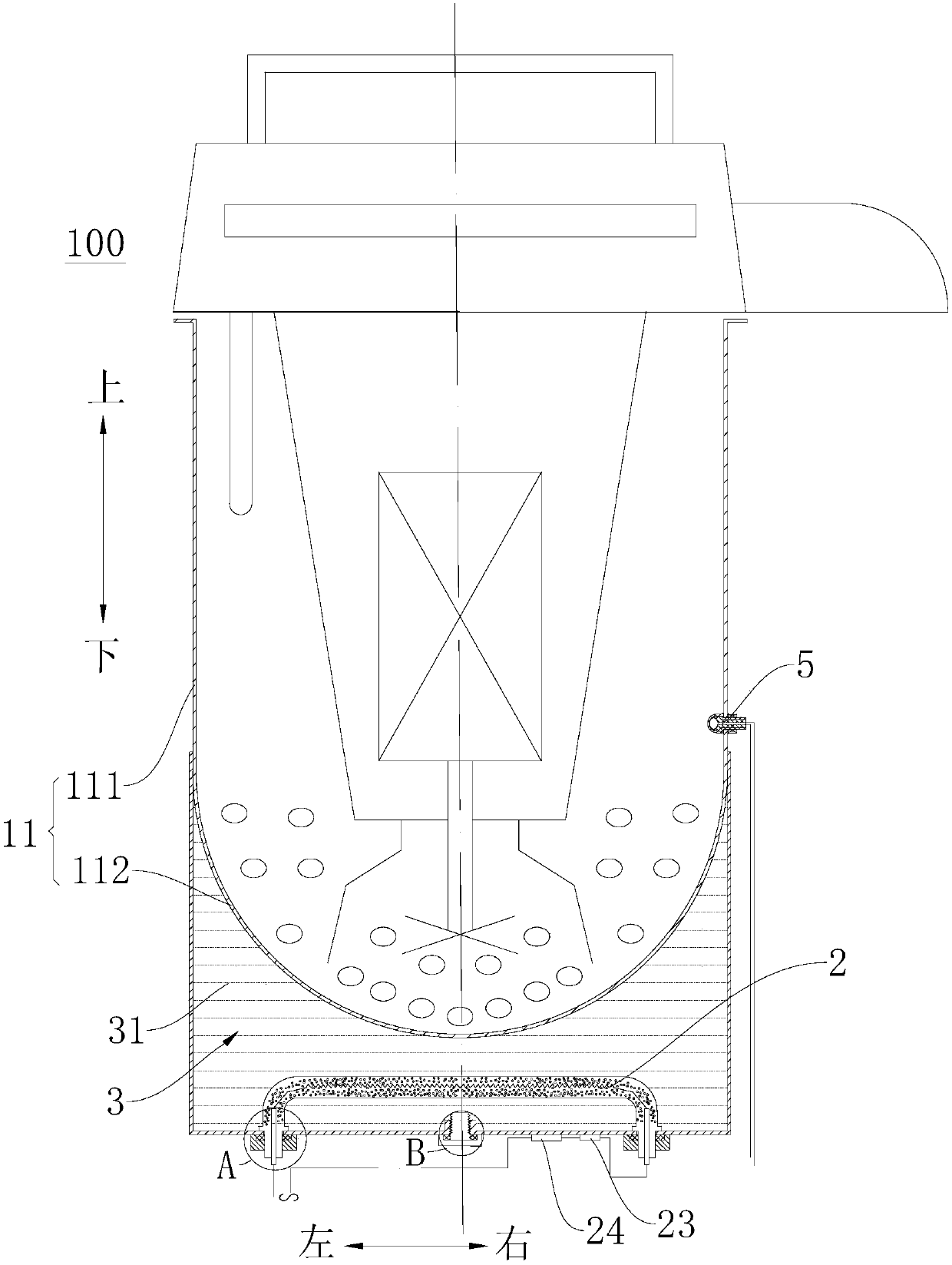

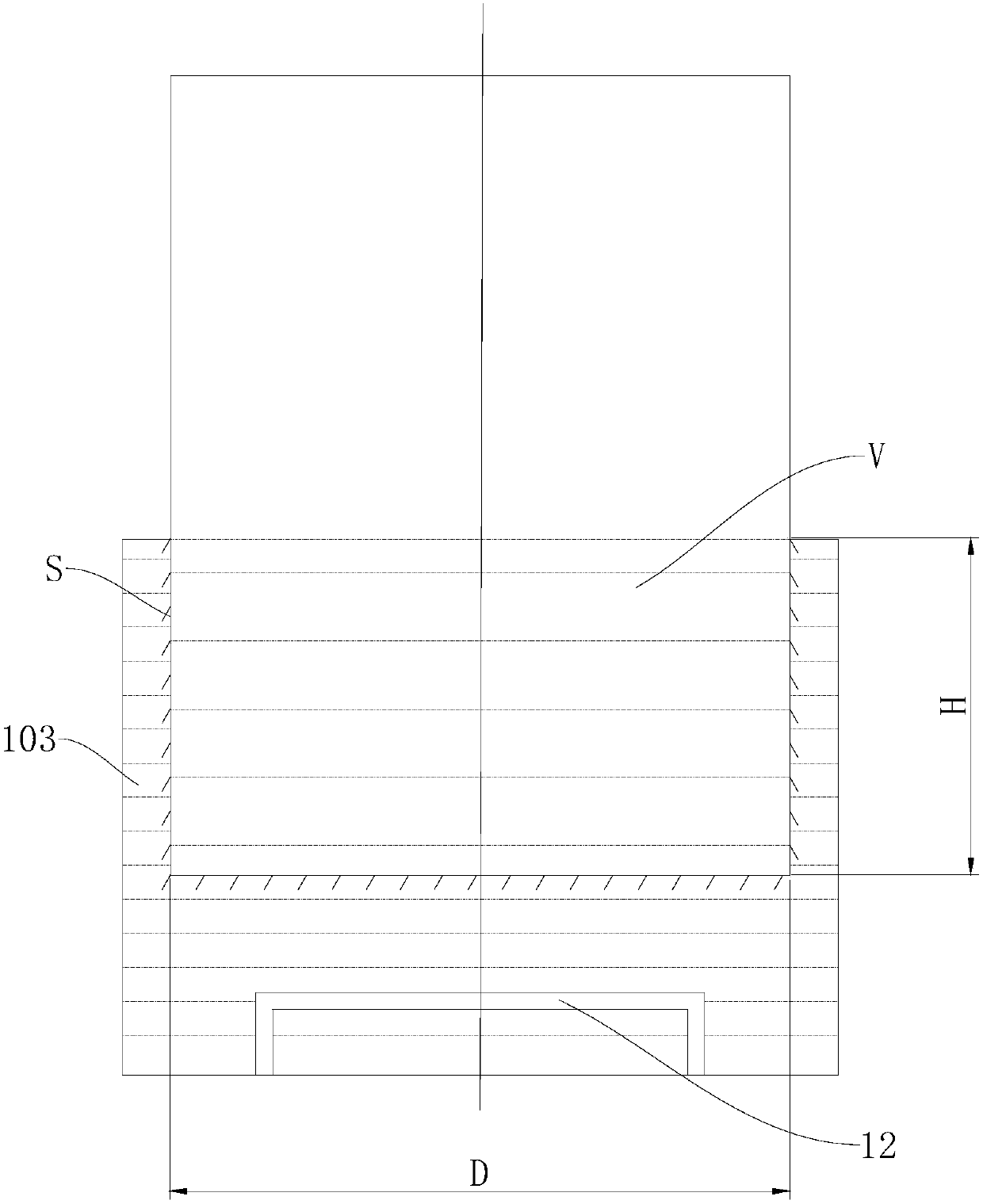

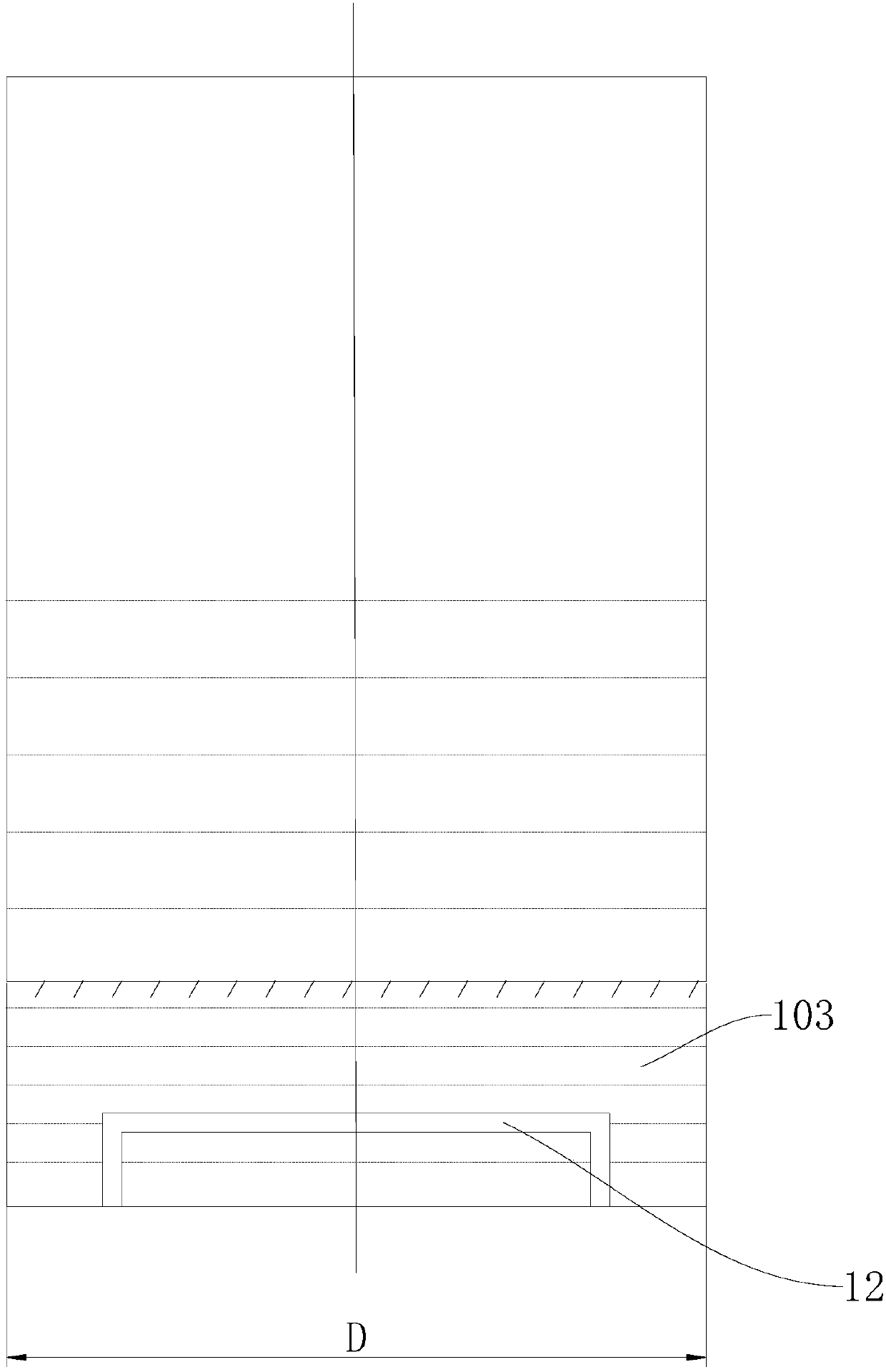

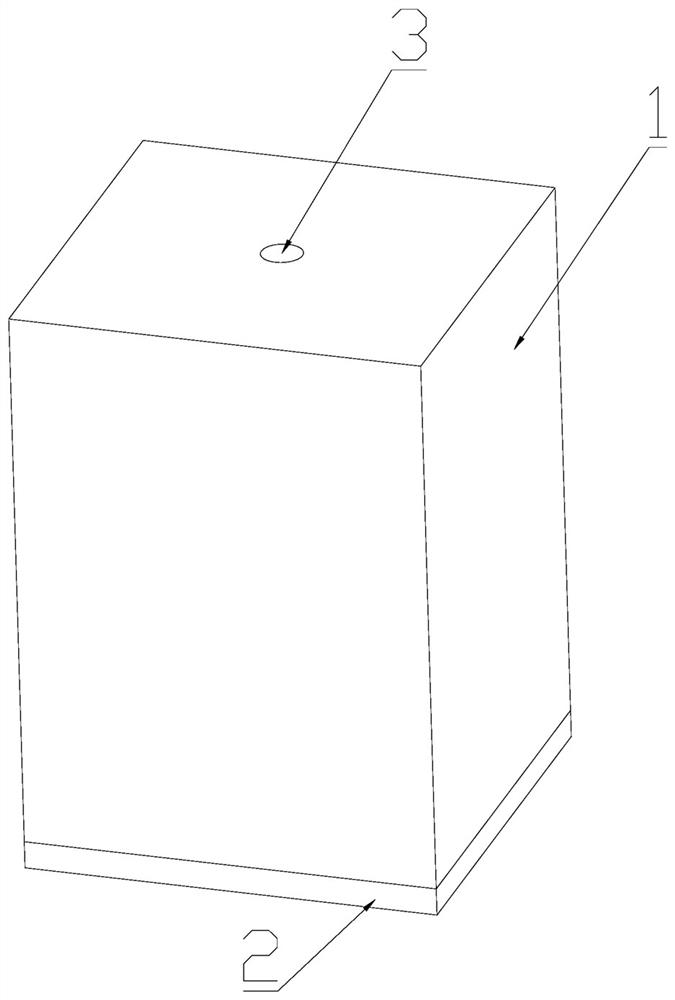

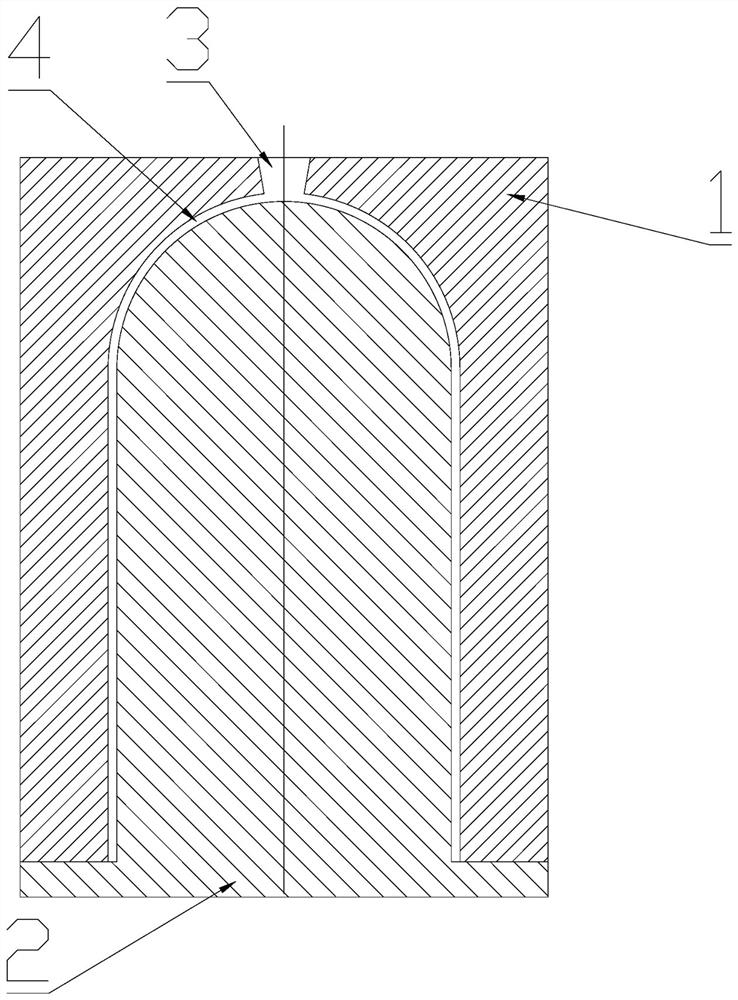

Heating container of food processor and food processor with same

InactiveCN107788876AControl the production processGood dispersionBeverage vesselsVessels with intergral heatingThermodynamicsEngineering

The invention discloses a heating container of a food processor and a food processor with the same. The heating container of a food processor comprises a cup body assembly, a heating element, and a temperature measuring element. The cup body assembly is internally provided with a heating cavity. The outer side of the heating cavity is provided with a heat conduction cavity. The heat conduction cavity covers at least a part of a cavity wall of the heating cavity. The heat conduction cavity is filled with a heat conduction medium, and the heat conduction medium contacts with the cavity wall of the heating cavity. The heating element is arranged on the cup body assembly and is used to heat the heat conduction medium, and the heating element is separated from the cavity wall of the heating cavity. The temperature measuring element is arranged on the cup body assembly and is used to detect temperature in the heating cavity. According to the heating container of a food processor, through arranging the temperature measuring element on the cup body assembly, temperature in the heating cavity can be detected, so as to accurately control a manufacturing process of fluid. Since the heat conduction cavity is arranged, and the heat conduction cavity is internally provided with the heat conduction medium, heat can be conducted through the heat conduction medium, providing convenience for dispersing heat, and providing convenience for uniform heating.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

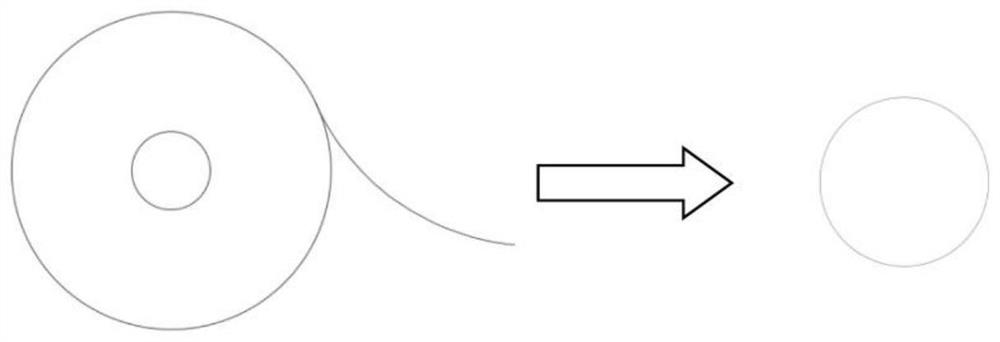

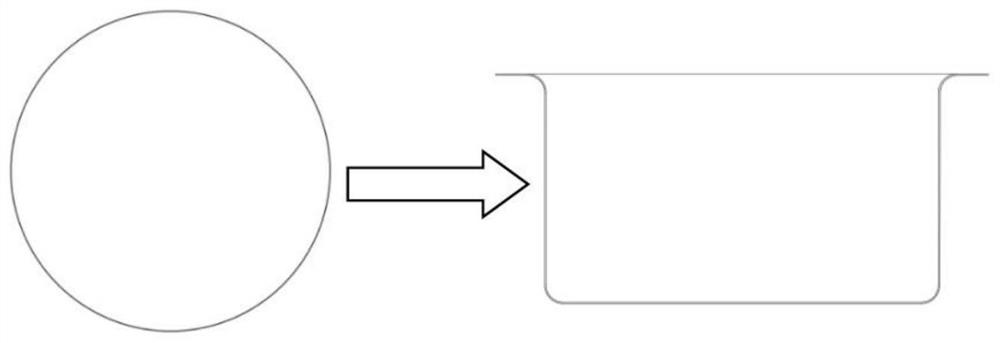

Aluminum alloy deep-drawing multifunctional cup and machining technology thereof

ActiveCN113441619AAvoid safety hazardsAbsorbentMetal working apparatusDrinking vesselsMachining processAluminium alloy

The invention relates to an aluminum alloy deep-drawing multifunctional cup and a machining technology thereof. The machining technology comprises the following steps of S1, aluminum material blanking; S2, primary cup forming; S3, primary stretching; S4, secondary stretching; S5, tertiary stretching; S6, quartus stretching; S7, quinary stretching; S8, trimming; S9, edge rolling of an opening part; S10, cleaning; S11, drying; and 12, packaging. According to the aluminum alloy deep-drawing multifunctional cup and the machining technology thereof, in the step S2, the width of a cup rim reserved aluminum material is compared with the reserved standard width of a cup rim through a central control module, the standard diameter size of a circular material sheet sheared in the step S1 is adjusted, in the step S3, the thickness of the stretched step part is compared with the standard step thickness through the central control module, the stretching speed of a primary stretching die part is adjusted, the central control module judges the thickness uniformity degree of the stretched step according to thickness difference values of all detection points, and adjustment is repeated in the steps S4, S5, S6 and S7.

Owner:PACIFIC CAN SHENYANG CO LTD

A biomimetic preparation method for swallowing food boluses

ActiveCN111920071BControl the production processLower control costsFood shapingPhysical medicine and rehabilitationFood bolus

The invention provides a bionic preparation method of swallowed food balls, which can monitor the formation process of swallowed food balls during the preparation process, the forming process is automatically completed, the crushing degree of swallowed food balls is controllable, and finally a complete molded and swallowed food ball can be obtained. Food boluses were used for follow-up studies. It includes the steps: S1: obtaining the food to be processed; it is characterized in that it also includes the following steps: S2: making a chewable capsule; S3: putting the food to be processed into the chewable capsule, according to the preset amount, inject artificial saliva into the chewing capsule; S4: seal the chewing capsule; S5: put the sealed chewing capsule in the mouth of the chewing robot; set the chewing motion parameters of the chewing robot; S6: After the chewing operation of the chewing robot is completed, obtain the chewable capsule; S7: Remove the chewable capsule to obtain a chewable and swallowed food mass.

Owner:JIANGNAN UNIV

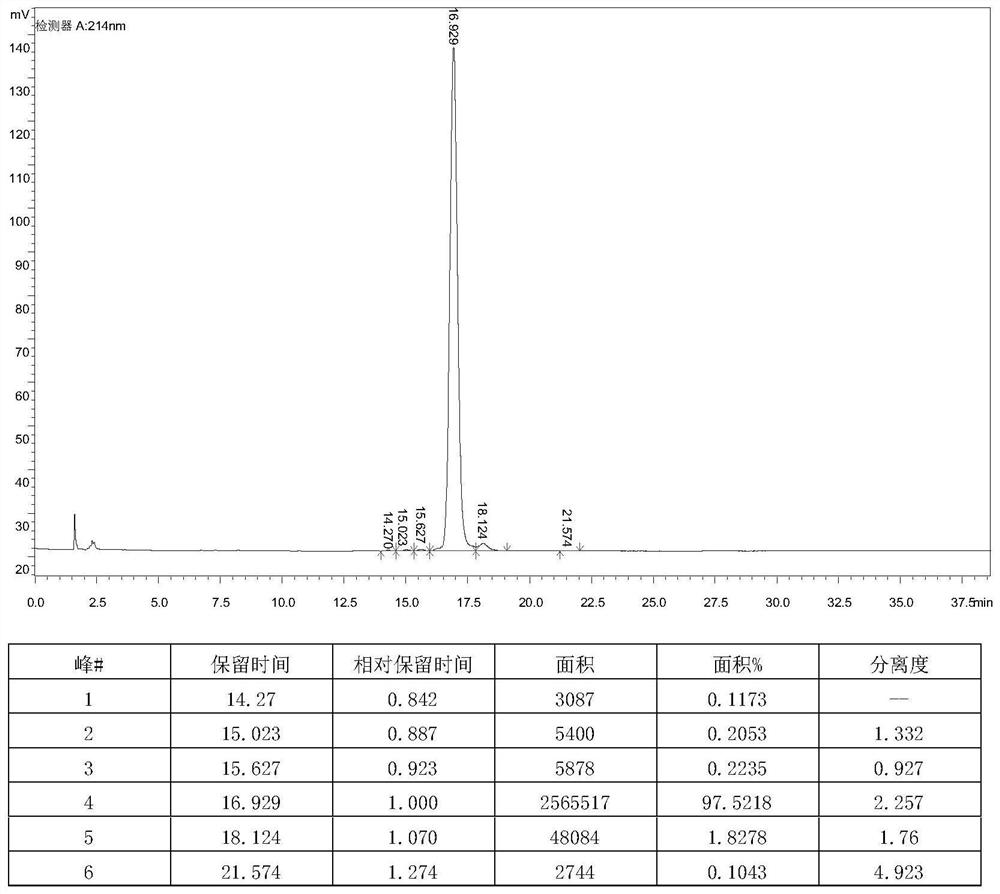

Method for preparing Daptomycin impurity RS-1 and impurity RS-3

PendingCN113929743AControl the production processImprove product qualityPeptide preparation methodsPhysical chemistryPharmaceutical drug

The invention belongs to the field of medicine preparation, and relates to a method for preparing a Daptomycin impurity RS-1 and impurity RS-3. The method specifically comprises the following steps of hydrolyzing a Daptomycin sample under an alkaline condition, hydrolyzing under an acidic condition, neutralizing with alkali, and finally purifying by preparative chromatography to obtain the Daptomycin impurity RS-1 and impurity RS-3. The method, which is provided by the invention, for preparing the Daptomycin impurity RS-1 and impurity RS-3 is simple and convenient in operation and low in cost, can be used for amplified preparation as required, and meets the requirements of research and production.

Owner:LUNAN PHARMA GROUP CORPORATION

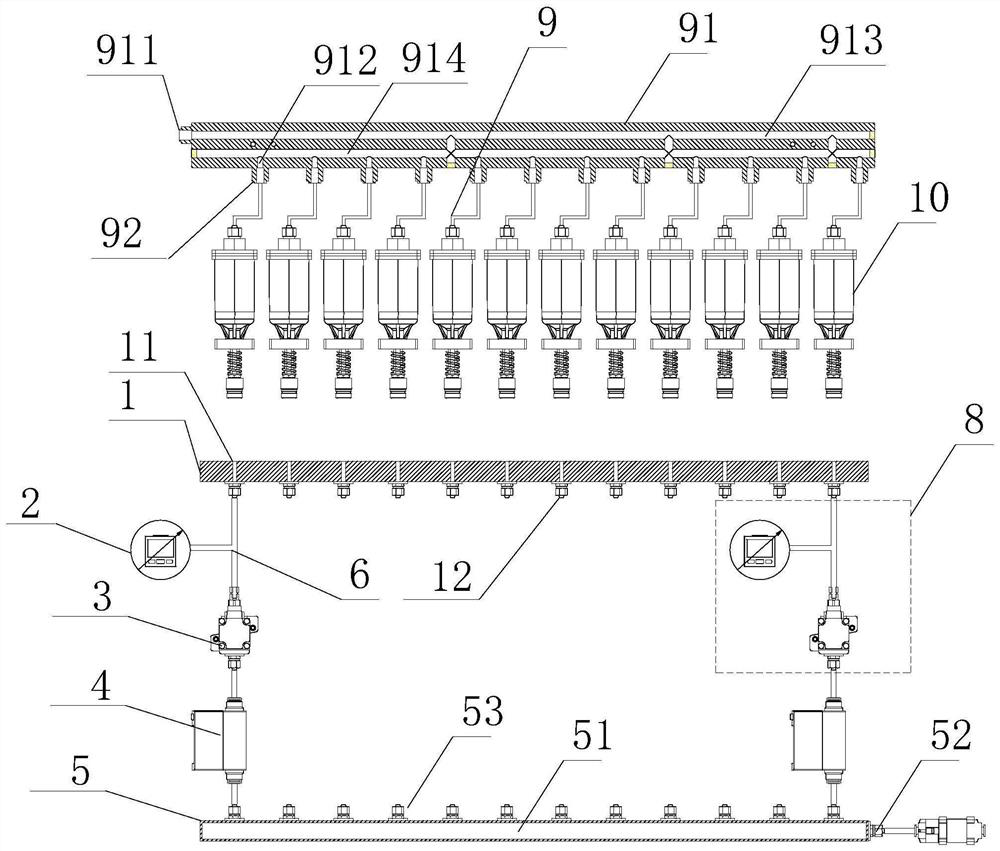

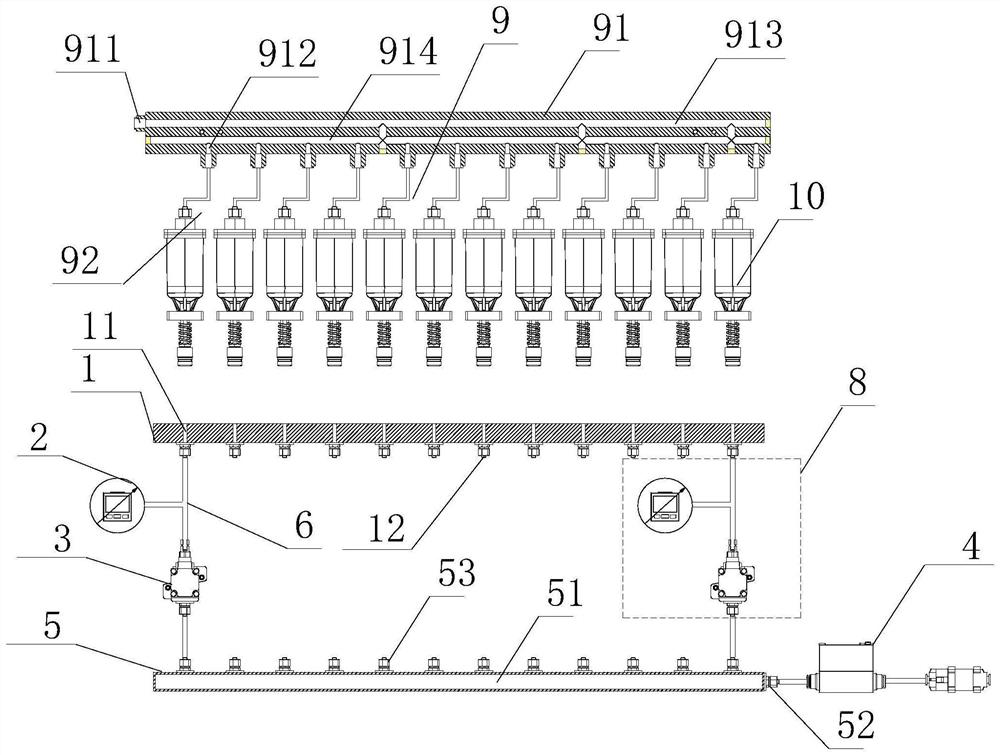

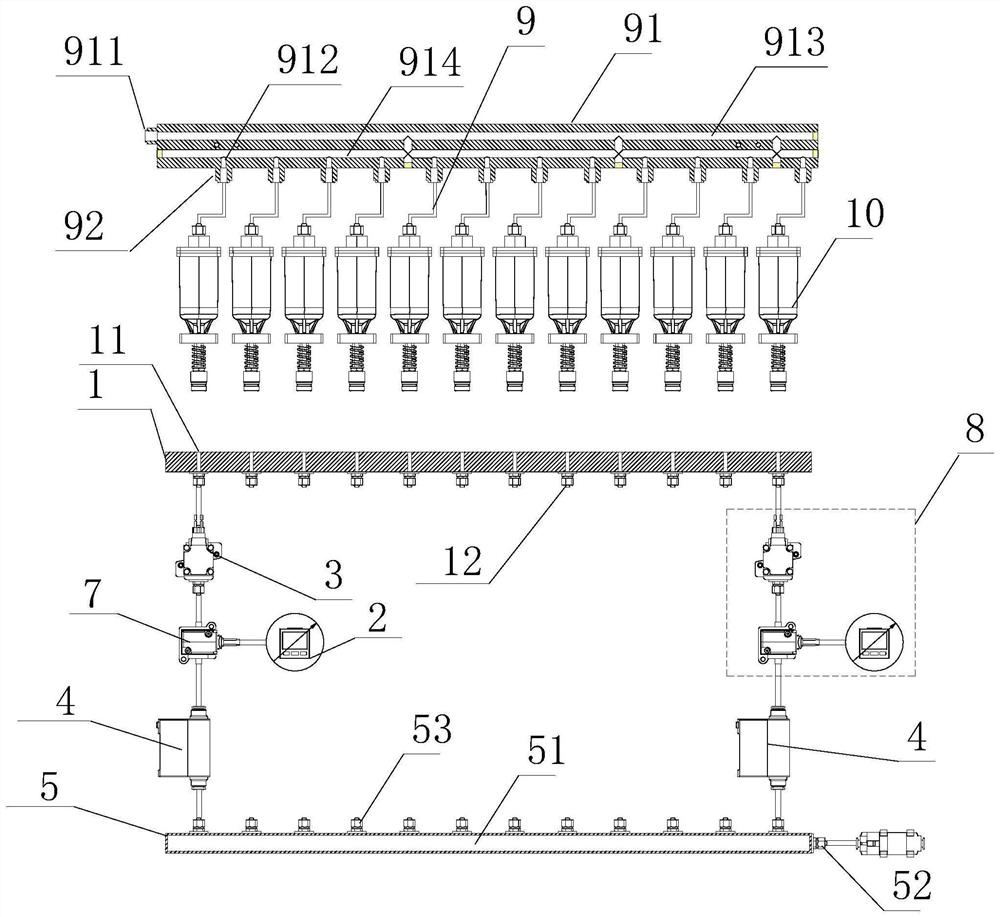

Lithium battery automatic detection tool and application method thereof

PendingCN114811445AImprove work efficiencyControl pressureSecondary cells charging/dischargingPipeline systemsBusbarStructural engineering

The invention discloses an automatic detection tool for a lithium battery. The automatic detection tool comprises a support, a busbar, a detection assembly and a flow meter, a plurality of liquid passing channels are formed in the support; one ends of the liquid passing channels are in one-to-one butt joint with negative pressure cup assemblies connected with a negative pressure pipeline of the formation equipment; a communicating opening is formed in the support; a confluence channel is arranged in the busbar; a confluence liquid outlet is formed in the end part of the busbar; confluence liquid inlets are formed in the busbar and are in one-to-one correspondence with the communicating ports; a detection liquid inlet of the detection assembly is communicated with the communication port pipeline; the detection liquid outlet is communicated with a confluence liquid inlet pipeline through a flow meter; or the detection liquid outlet of the detection assembly is communicated with the confluence liquid inlet pipeline, and the confluence liquid outlet is communicated with the flow meter; the invention further discloses an application method for testing the single-channel flow and the overall flow of the negative pressure system pipeline of the formation equipment and whether the pipeline is blocked or not. The device has the beneficial effects that gas pressure leakage detection and blockage can be controlled, and the working efficiency is improved.

Owner:ZHEJIANG HANGKE TECH

Microbial source research method for tank expansion and juice leakage of fermented bean curd

PendingCN114058670AControl the production processEasy to operateMicrobiological testing/measurementMicroorganism based processesBiotechnologyYeast

The invention discloses a microbial source research method for tank expansion and juice leakage of fermented bean curd. The specific research method comprises the following steps: 1, taking a research and development center, a quality department and a technical department as main technical teams, taking charge of examining and approving the project scheme design and providing modification suggestions, finally determining a scheme and an implementation method, and by management personnel, performing technical disclosure work on field researchers and testers; and 2, extracting normal fermented bean curds and problem fermented bean curds in the same batch of production for microbiological detection, and mainly determining the total number of bacterial colonies and the number of yeasts, bacilli and lactic acid bacteria in the fermented bean curds. The aerogenic bacteria are separated and identified from the tank expansion juice leakage fermented bean curd product, the root cause causing the quality problem of the fermented bean curd is mastered, and the microbial evolution process of fermented bean curd fermentation and the influence of the microbial evolution process on the product quality are known by detecting the microbial introduction condition in each procedure of fermented bean curd production.

Owner:鹤山市东古调味食品有限公司

A kind of manufacturing method of high precision ntc thermistor chip

ActiveCN106699158BAvoid decompositionImprove pass rateNegative temperature coefficient thermistorsDecompositionPass rate

The invention discloses a method for manufacturing a high-precision NTC thermistor chip. The method comprises a step 1) of weighing corresponding metal oxides according to a chemical formula Mn3-x-y-zNixFeyCozQtO4, performing mixing ball-milling, low-temperature calcination, ball-milling crushing and high-temperature calcination, and obtaining thermal sensitive ceramic powder; a step 2) of performing ball-milling on the thermal sensitive ceramic powder, adding an organic binder, and performing drying, pelleting and sieving to obtain formed powder; a step 3) of performing dry pressing and isostatic pressing on the formed powder, and obtaining formed briquette; a step 4) of adding the formed briquette into an atmosphere furnace, performing sintering in the weak oxidizing atmosphere, and obtaining agglomerate; a step 5) of cutting the agglomerate into slices, coating the slices with silver or gold electrodes, performing heat treatment, cutting the slices into required sizes, and obtaining the high-precision NTC thermistor chip. The decomposition of FeMnNiO4 is restrained by controlling oxygen partial pressure in the sintering process, ingredient segregation is reduced by introducing low-temperature calcination before presintering, the production process is controlled easily, the chip resistance and B value pass rate are high, and the reliability is high.

Owner:GUANGZHOU MAGNET ELECTRICITY

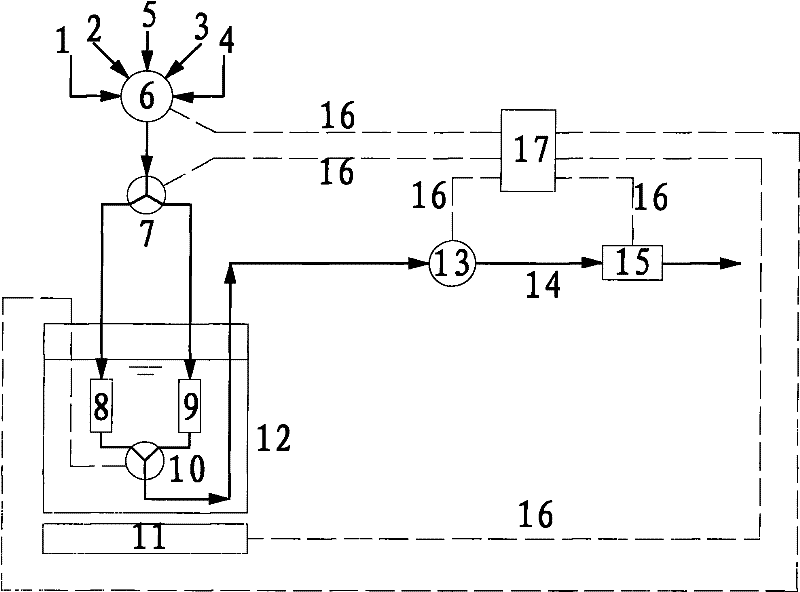

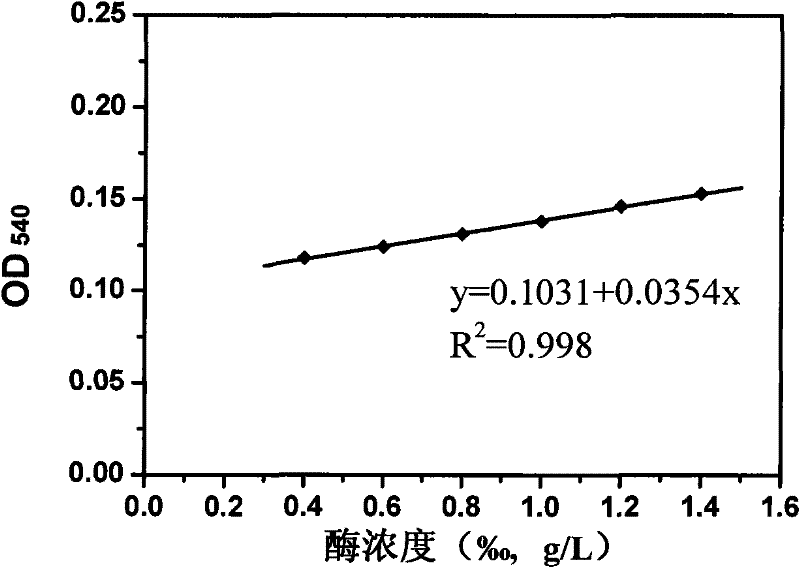

A single-channel enzyme activity automatic detection device

InactiveCN101788462BMeet control requirementsEasy detectionPreparing sample for investigationColor/spectral properties measurementsWater bathsBiochemical engineering

The invention discloses a single-channel enzyme activity automatic detection device, which belongs to the field of biological enzyme application and biotechnology. The single-channel enzyme activity automatic detection device includes a sample injection part, a reaction part, a water bath part, a stirring part, a driving part, a detection part and a control part; The orderly work of the part and the detection part can realize the semi-continuous automatic detection of enzyme activity, avoid the error caused by human operation, and can detect the enzyme activity of various enzyme systems used in industrial production. The detection frequency is 1 time / 20min~ 1 time / 15min, the measurement accuracy is 0.01U / mL. The invention can not only measure the activity of the enzyme conveniently, rapidly and accurately, and meet the control requirements of the enzymatic reaction process, but also has simple structure, reasonable design, low cost, and is convenient for popularization and application.

Owner:TSINGHUA UNIV +1

Device for detecting negative pressure leakage

PendingCN114544110AControl the production processQuick checkMeasurement of fluid loss/gain rateMechanical engineeringElectrical and Electronics engineering

The invention discloses equipment for detecting negative pressure leakage detection. The equipment comprises a detection box, a negative pressure butt joint assembly and a negative pressure detection part, the detection box comprises an outer box body and an inner support, and a detection cavity is formed in the outer box body; the inner support is arranged in the detection cavity of the outer frame body; the negative pressure butt joint assembly comprises a plurality of negative pressure detection columns which are parallel to one another, the negative pressure detection columns are arranged on the top of the outer box body side by side in pairs, and every two negative pressure detection columns in pairs are connected with each other through a connecting rod; the negative pressure detection component is arranged in the detection cavity of the outer box body and comprises a digital display meter and a digital display meter mounting piece, the digital display meter is arranged in the detection cavity of the outer box body through the digital display meter mounting piece, and an external connector of the digital display meter is communicated with the negative pressure detection column pipeline. The gas leakage detection device has the beneficial effects that whether gas in the negative pressure pipeline of the formation equipment leaks or not can be rapidly detected, the production process of gas pressure leakage detection can be controlled, and the working efficiency is greatly improved.

Owner:ZHEJIANG HANGKE TECH

Preparation method of rice noodles

ActiveCN103005299BControl the production processThe production process is easy to controlFood preparationAlpha-amylaseSteaming

The invention discloses a preparation method of rice noodles. The preparation method comprises the steps of fermenting a raw material, resisting aging, grinding into pulp and steaming and further comprises the step of resisting aging secondarily after the steaming step, wherein the step of resisting aging secondarily comprises the substeps of contacting amylase with a rice slice obtained in the steaming step and putting aside the rice slice for 20-80 minutes at 30-80 DEG C; the amylase is alpha-amylase and / or beta-amylase; and the raw material is rice and / or unpolished rice. By the preparation method, the production process can be conveniently controlled, the rice noodles can be produced on a large scale, and the produced rice noodles are stable in quality and long in shelf life.

Owner:湖南湘粮食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com