Method for preparing Daptomycin impurity RS-1 and impurity RS-3

A technology of daptomycin and RS-1, which is applied in the field of preparation of daptomycin impurity RS-1 and impurity RS-3, can solve the problems of large consumption of mobile phase, high preparation cost, high operation difficulty, etc. Time savings, low source requirements, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

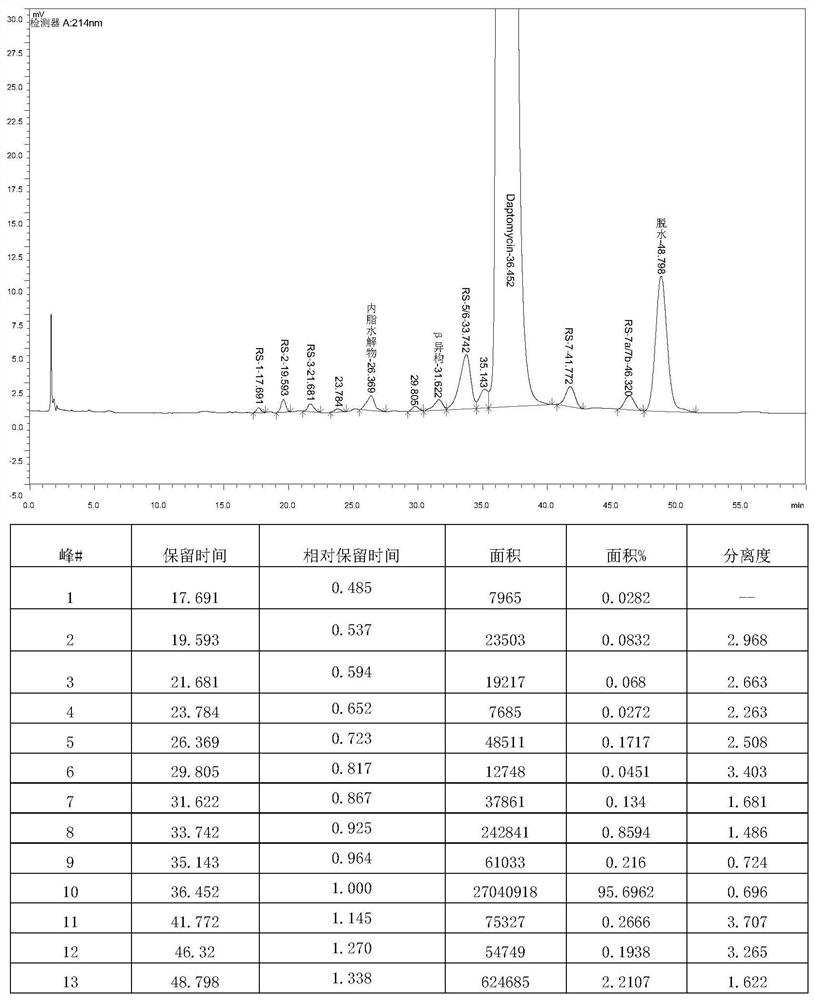

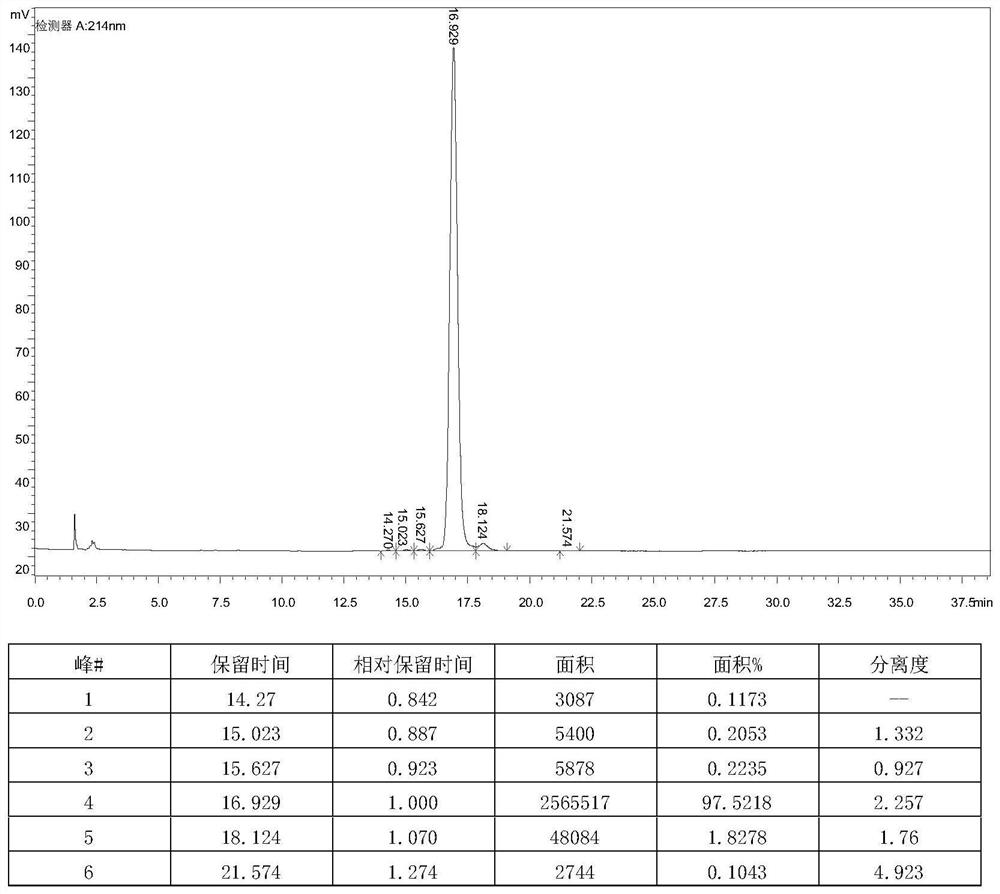

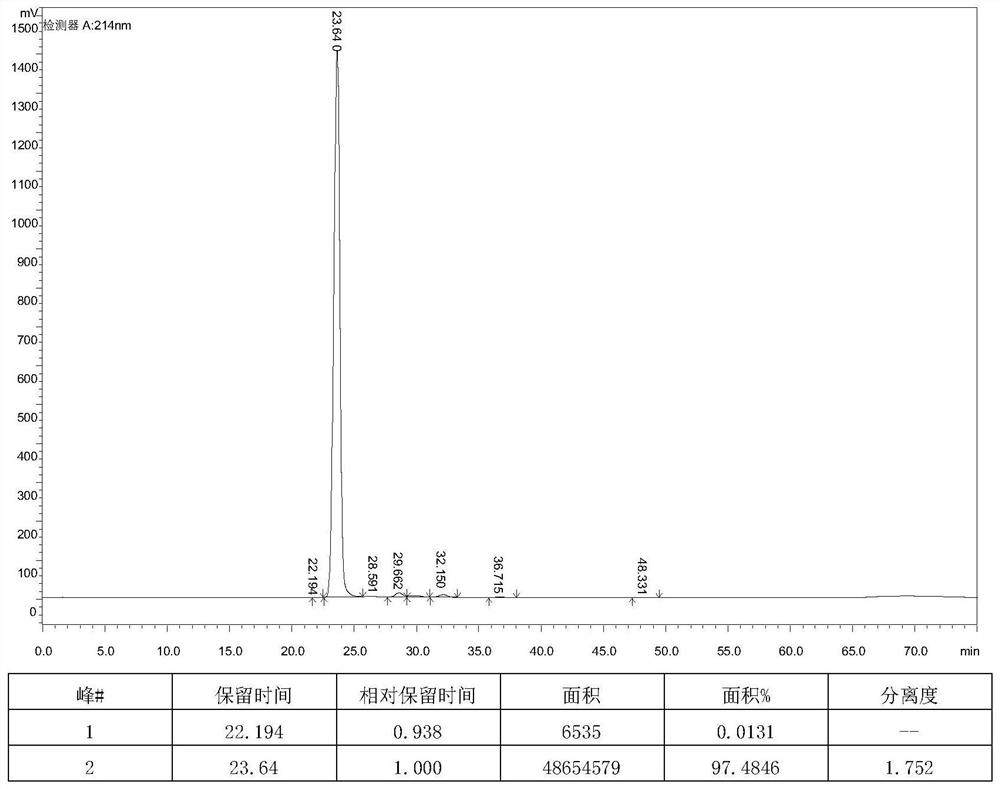

[0065] Get the daptomycin finished product (5g) of chromatographic purity 95%, dissolve it into a 50mg / mL solution with purified water, then add 1mol / L sodium carbonate solution to the aqueous solution containing daptomycin to adjust the pH of the reaction solution to 10.0, placed in a constant temperature water bath at 60°C, and heated for 5 hours to obtain an alkaline hydrolyzate; then add 0.1mol / L hydrochloric acid solution to the alkaline hydrolyzate to adjust the pH of the reaction solution to 2.0, and place at a constant temperature of 80°C In the water bath, heat the reaction for 7h; add 0.02mol / L sodium hydroxide solution to the acidic hydrolyzate, adjust the pH of the reaction system to be 7.0, and obtain a solution containing daptomycin impurities RS-1 and RS-3 (HPLC The purity of impurities RS-1 and RS-3 in the detection solution is 16.7% and 21.6% respectively); the solution containing daptomycin impurities RS-1 and RS-3 is through preparative chromatography (the ch...

Embodiment 2

[0067] Take daptomycin powder injection (2g), dissolve it into a 50 mg / mL solution with purified water, then add 0.5 mol / L potassium carbonate solution to the aqueous solution containing daptomycin, adjust the pH of the reaction solution to 10.5, and place Heat and react in a constant temperature water bath at 65°C for 6 hours to obtain an alkaline hydrolyzate; then add 0.2mol / L sulfuric acid solution to the alkaline hydrolyzate to adjust the pH of the reaction solution to 1.6, and place it in a constant temperature water bath at 75°C , heating and reacting for 8h; Add 0.01mol / L potassium hydroxide solution to the acidic hydrolyzate, adjust the pH of the reaction system to be 7.0, obtain the solution mainly containing daptomycin impurity RS-1 and RS-3 (HPLC detection solution The impurities RS-1 and RS-3 have a purity of 16.2% and 21.1% respectively); the solution containing the daptomycin impurities RS-1 and RS-3 is preparatively chromatographic (the chromatographic column is ...

Embodiment 3

[0069] Get the daptomycin finished product (5g) of chromatographic purity 90%, dissolve it into a 50mg / mL solution with purified water, then add 0.8mol / L potassium carbonate solution to the aqueous solution containing daptomycin to adjust the pH of the reaction solution to 9.5, placed in a constant temperature water bath at 63°C, and heated for 4 hours to obtain an alkaline hydrolyzate; then add 0.3mol / L sulfuric acid solution to the alkaline hydrolyzate to adjust the pH of the reaction solution to 3.0, and place at 77°C In a constant temperature water bath, heat and react for 6 hours; then add 0.03mol / L potassium hydroxide solution to the acidic hydrolyzate, adjust the pH of the reaction system to 7.0, and obtain a solution mainly containing daptomycin impurities RS-1 and RS-3 (the purity of impurities RS-1 and RS-3 in the HPLC detection solution is 16.3% and 21.0% respectively); the solution containing daptomycin impurities RS-1 and RS-3 is through preparative chromatography ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com