A single-channel enzyme activity automatic detection device

An automatic detection device, single-channel technology, applied in the preparation of test samples, color/spectral property measurement, etc., can solve the problems of unfavorable enzymatic reaction process control, low analysis accuracy, poor reproducibility, etc., to achieve semi-continuous The effect of automatic detection, meeting control requirements and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

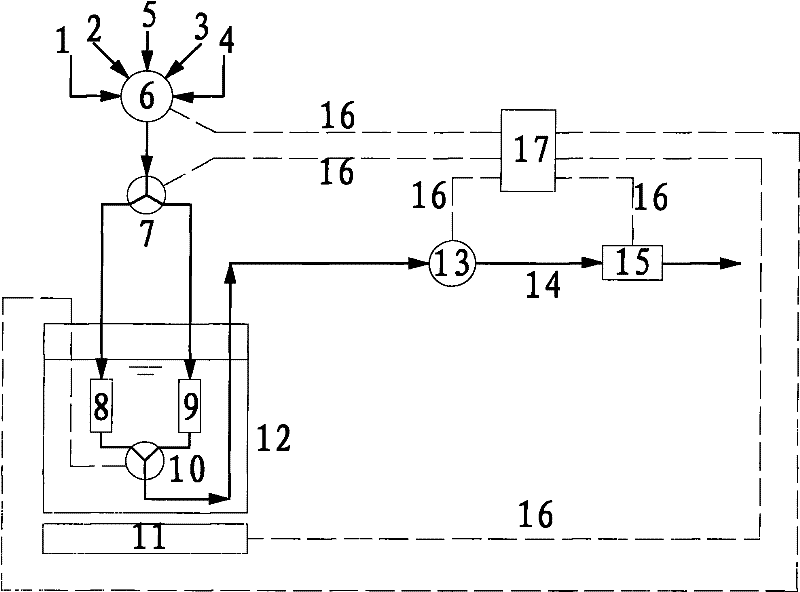

[0027] A single-channel enzyme activity automatic detection device, the single-channel enzyme activity automatic detection device includes a sample injection part, a reaction part, a water bath part, a stirring part, a driving part, a detection part and a control part; the schematic diagram of the device is as follows: figure 1 shown;

[0028] The sample injection part is a multifunctional rotary ball valve 6, which is divided into two parts: an outer shell and an inner sphere, both of which are in smooth contact and have good sealing performance; the outer shell is provided with a number of ports along the largest horizontal circumference, respectively connected to the sample and detection reagent injection tubes (the number of injection tubes can be determined according to the actual situation, and the number of injection tubes in this embodiment is 5, which are represented by labels 1, 2, 3, 4 and 5 respectively), and there is only one injection tube on the inner sphere Ope...

Embodiment 2

[0036] Adopt the device described in embodiment 1 to carry out the mensuration of pectinase enzymatic activity

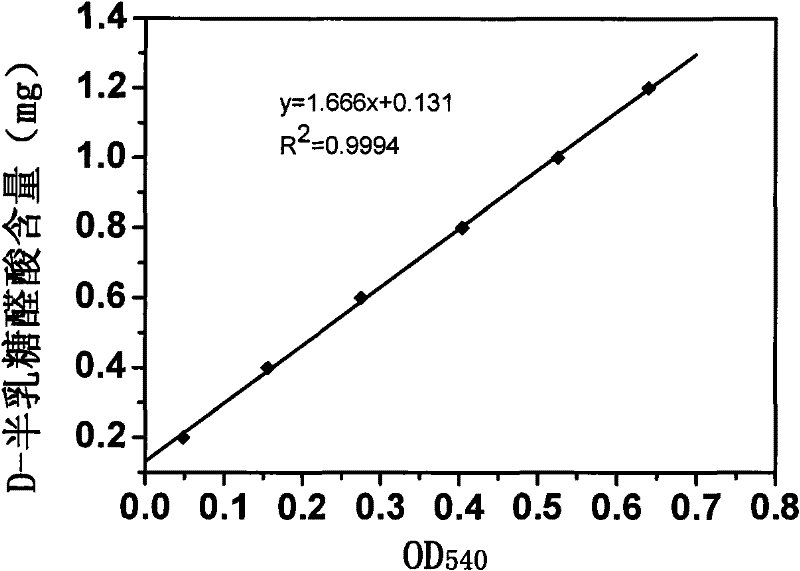

[0037] The enzyme activity unit U of pectinase is defined as: the amount of enzyme required to produce 1 mg of D-galacturonic acid per minute under certain temperature and pH conditions. The principle of this device is to measure the amount of reducing sugar produced by enzymatic reaction by DNS method, and then convert it into enzyme activity.

[0038] 1. Preparation of reagents:

[0039] (1) D-galacturonic acid solution

[0040]Take the D-galacturonic acid solution with a concentration of 1 mg / mL and prepare 100 mL of dilute solutions of 0.1 mg / mL, 0.2 mg / mL, 0.3 mg / mL, 0.4 mg / mL, 0.5 mg / mL and 0.6 mg / mL respectively .

[0041] (2) DNS reagent

[0042] Weigh 91.0g of potassium sodium tartrate, dissolve it in 250mL of distilled water, heat (not exceeding 50°C), add 3.15g of 3,5-dinitrosalicylic acid, 10.5g of NaOH, 2.5g of phenol, and no Water sodium sulfite 2...

Embodiment 3

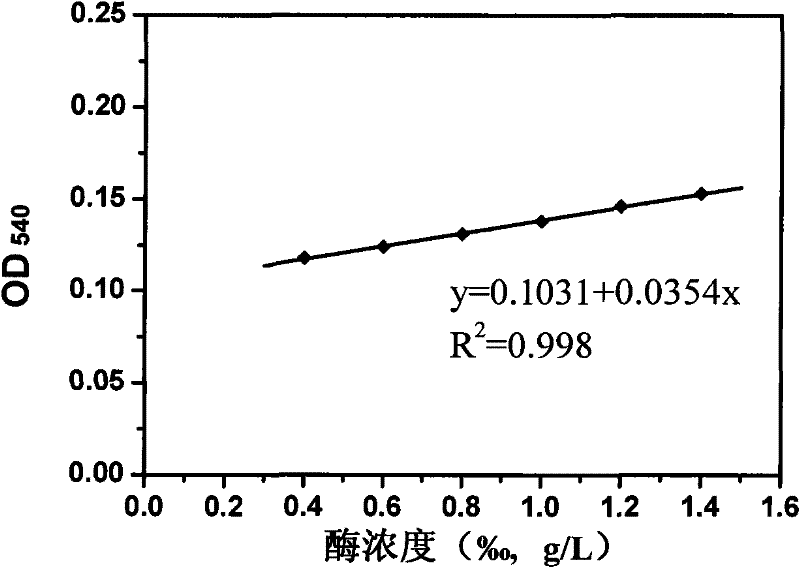

[0052] Process control method for continuous enzymatic pretreatment of cotton fabric

[0053] The enzyme activity detection device detects the activity of the enzyme liquid in the continuous enzyme pretreatment working tank of cotton fabrics, so as to adjust the supply speed of the enzyme liquid in the working tank, so that the activity of the enzyme liquid in the working tank can be stabilized within a certain range, and the cotton fabric products can be guaranteed. quality.

[0054] (1) Pectin solution

[0055] Weigh 1 g of pectin and dissolve it in 50 mL of sodium hydroxide / disodium hydrogen phosphate buffer solution with a pH value of 8.0, and finally set the volume to 100 mL.

[0056] (2) Alkaline pectin solution

[0057] Weigh 1 g of pectin and dissolve it in 50 mL of sodium hydroxide / KCl buffer solution with a pH value of 13.0, and finally set the volume to 100 mL.

[0058] (3) Pectinase solution

[0059] Dilute 1mL pectinase with sodium hydroxide / disodium hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com