Accurate control method for preparation process of oat fermentation extract

A technology of oat extract and preparation process, which is applied in the directions of pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of affecting application performance, reducing the stability of oat extract cosmetic raw materials, poor extraction effect, etc., and achieves active The effect of increasing the content of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

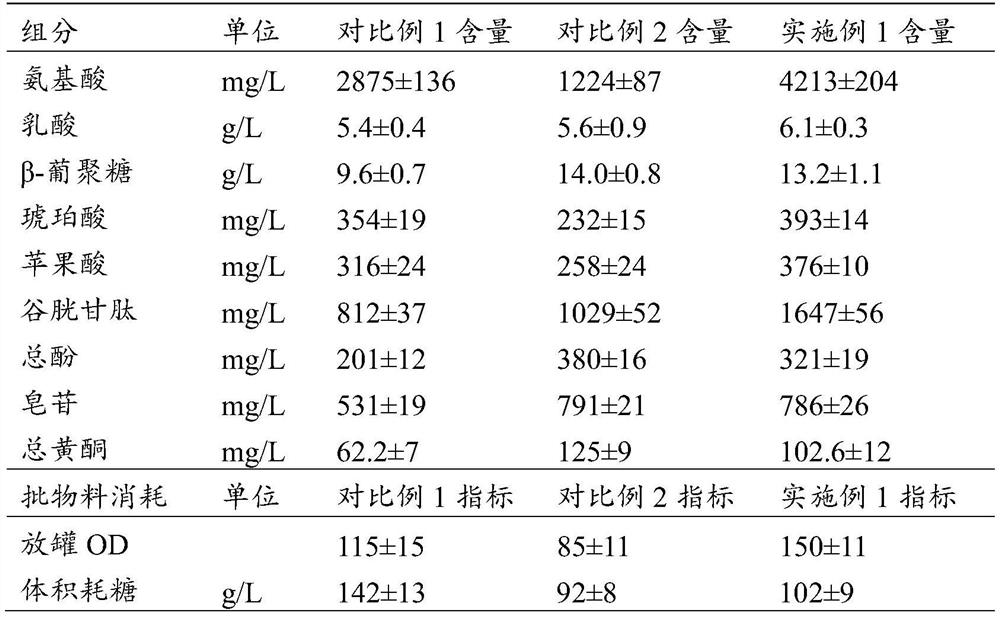

Examples

Embodiment 1

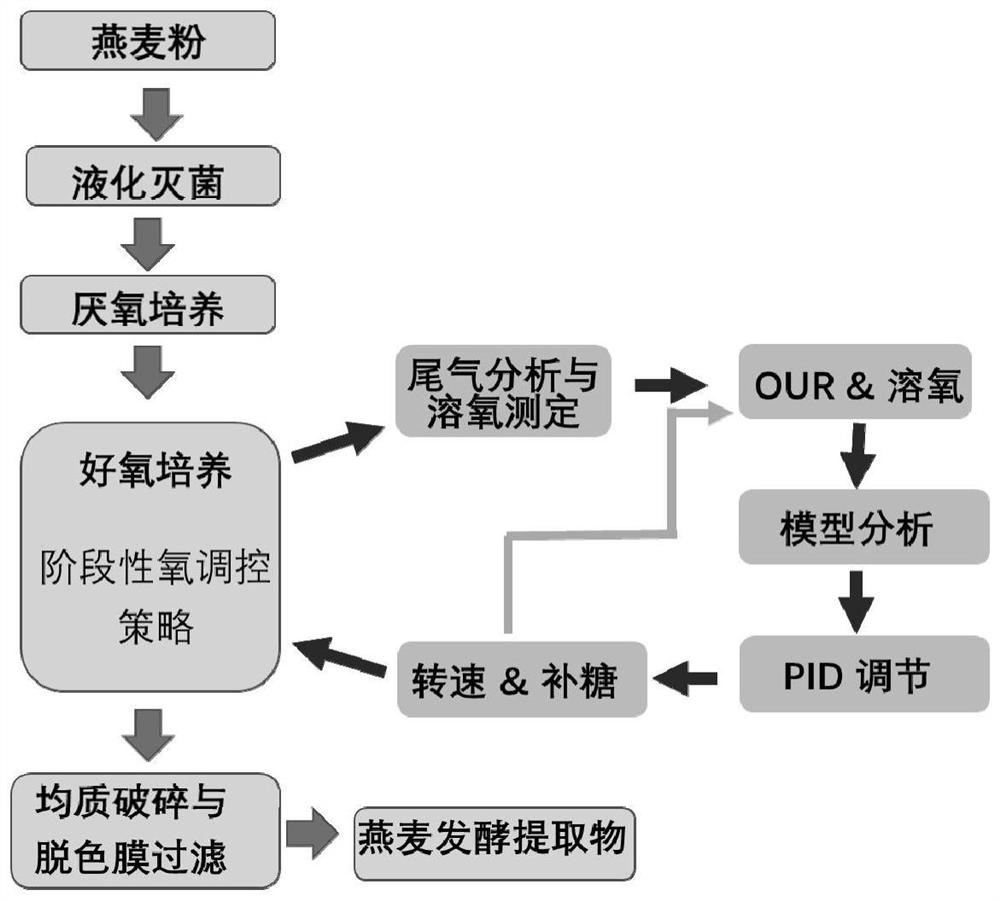

[0054] The present embodiment provides a kind of precise control method of oat fermented extract preparation process, and this method comprises the following steps:

[0055] Step 1. Anaerobic fermentation process: disperse oat flour with purified water, heat to 100°C for gelatinization, liquefy at 85°C with liquefaction enzyme 300U / L, add auxiliary materials to prepare fermentation medium, and sterilize at 121°C for 30 minutes; the content of auxiliary materials is: 0.5% of yeast extract powder, 0.5% of peptone, 0.5% of diammonium hydrogen phosphate, and 0.02% of defoamer.

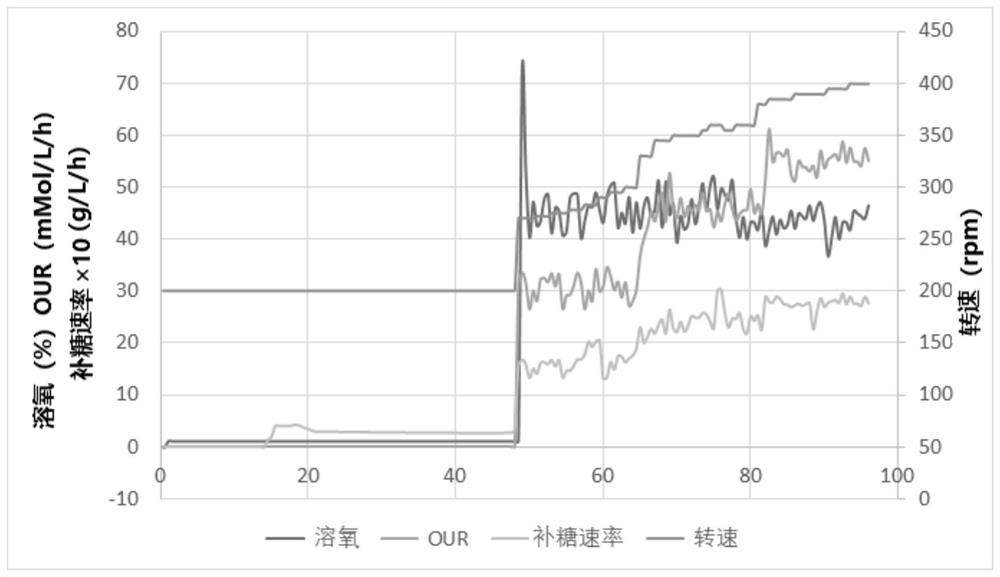

[0056] Inoculate the well-grown Bifidobacterium aureus seed culture solution into the fermenter according to 10% inoculation amount, control the temperature at 37.5-38.5°C, the fermenter rotates at 200rpm, maintains the anaerobic culture environment with nitrogen, and intermittently controls the pH to 5.5 with ammonia water; When the sugar concentration drops to 0.4g / L, sugar supplementation is started, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com