Bending measurement and material selection equipment for bamboo ribs of folding fan

A bending and equipment technology, applied in the direction of mechanical diameter measurement, angle/taper measurement, sorting, etc., can solve the problems of high labor intensity, relying on manual operation, difficult to ensure the quality of material selection, etc., to achieve strong directivity and accuracy. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

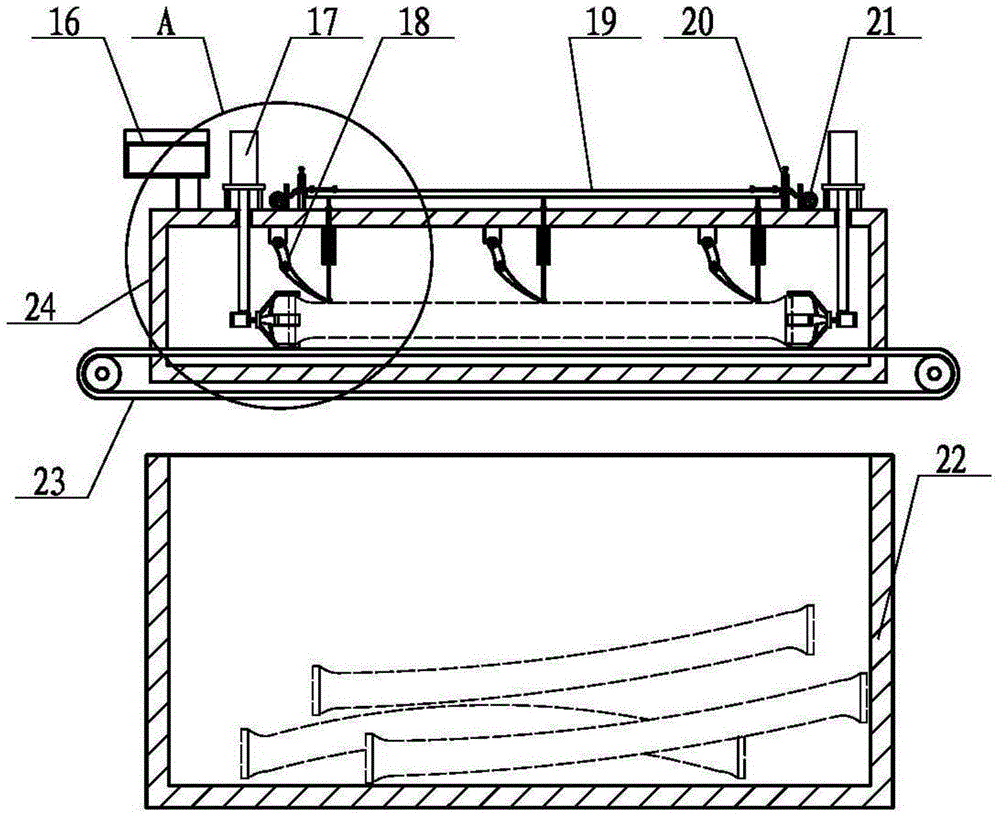

[0024] Such as figure 1 As shown, a kind of equipment for measuring bending and selecting materials for folding fan bamboo bones includes a frame, and a conveyor belt is arranged under the frame, and the bamboo material is moved to the bottom of the frame by the conveyor belt, and a camber detection device is set on the frame, and the camber detection The device includes more than three curvature probes, and each curvature probe is detected by an arc probe. The upper end of the arc probe is hinged on the frame, and the lower end of the arc probe is hinged to the lower end of the sliding guide column. When running to the arc-shaped probe, due to the difference in the diameter of the bamboo tube, the arc-shaped probe will be pushed up to varying degrees.

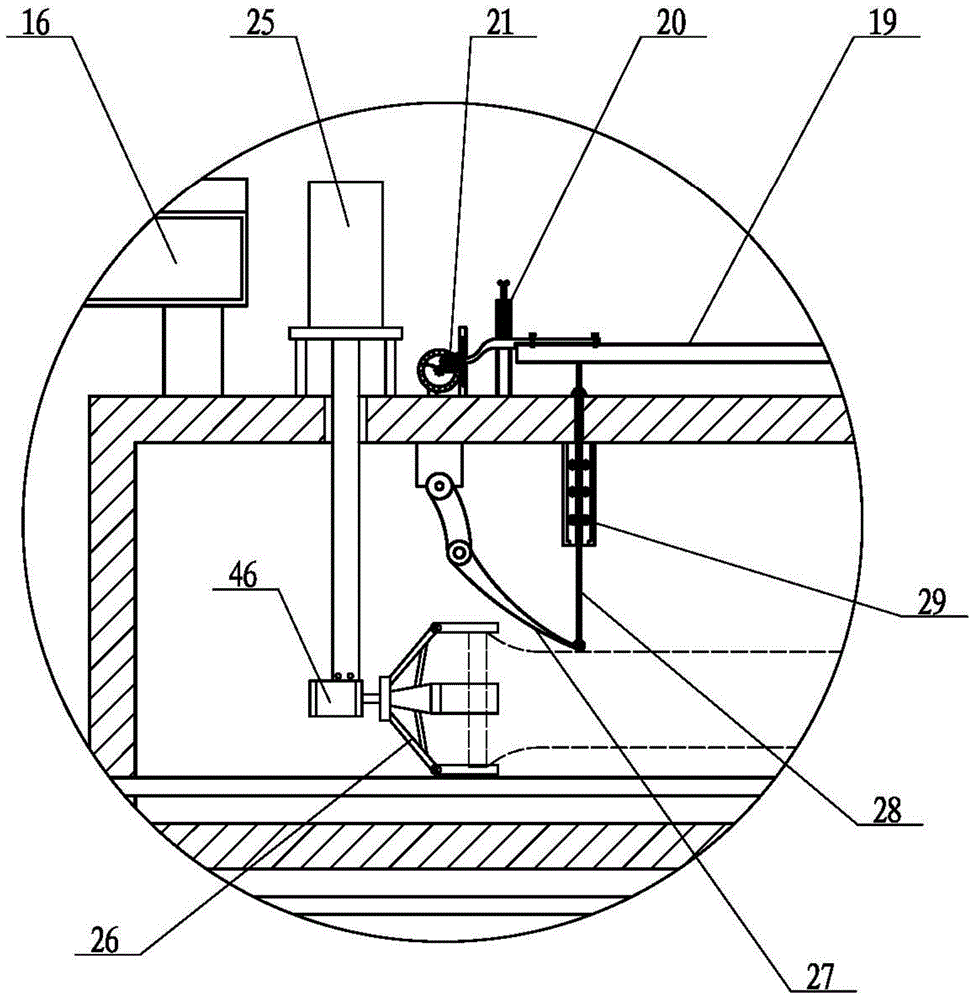

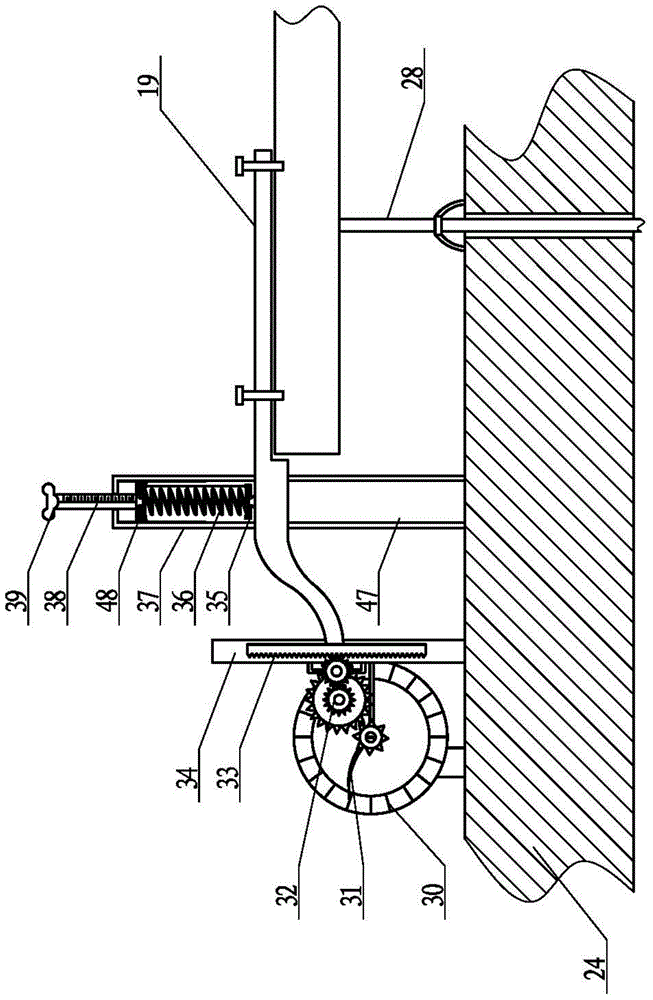

[0025] Such as figure 2 and 3 As shown, the upper end of the sliding guide column is connected to and supports the balance bar, and a displacement measuring device is installed at both ends of the balance bar. The displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com