Heating container of food processor and food processor with same

A technology for a food processor and a heating container, which is applied to utensils with integral electric heating devices, cooking utensils, household utensils, etc., can solve the problems of limited function and low efficiency, and achieve the effects of convenient dispersion, convenient heating and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

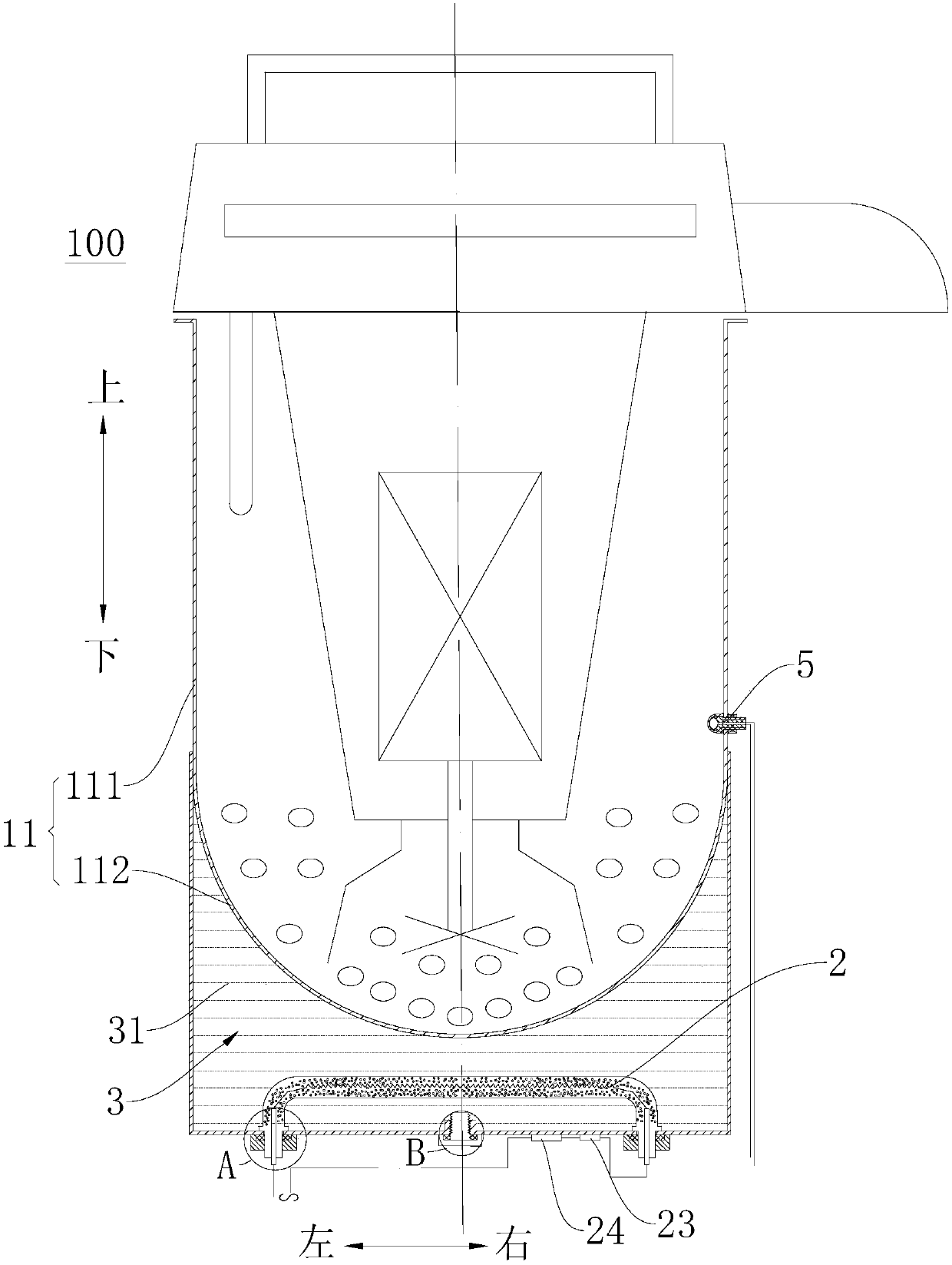

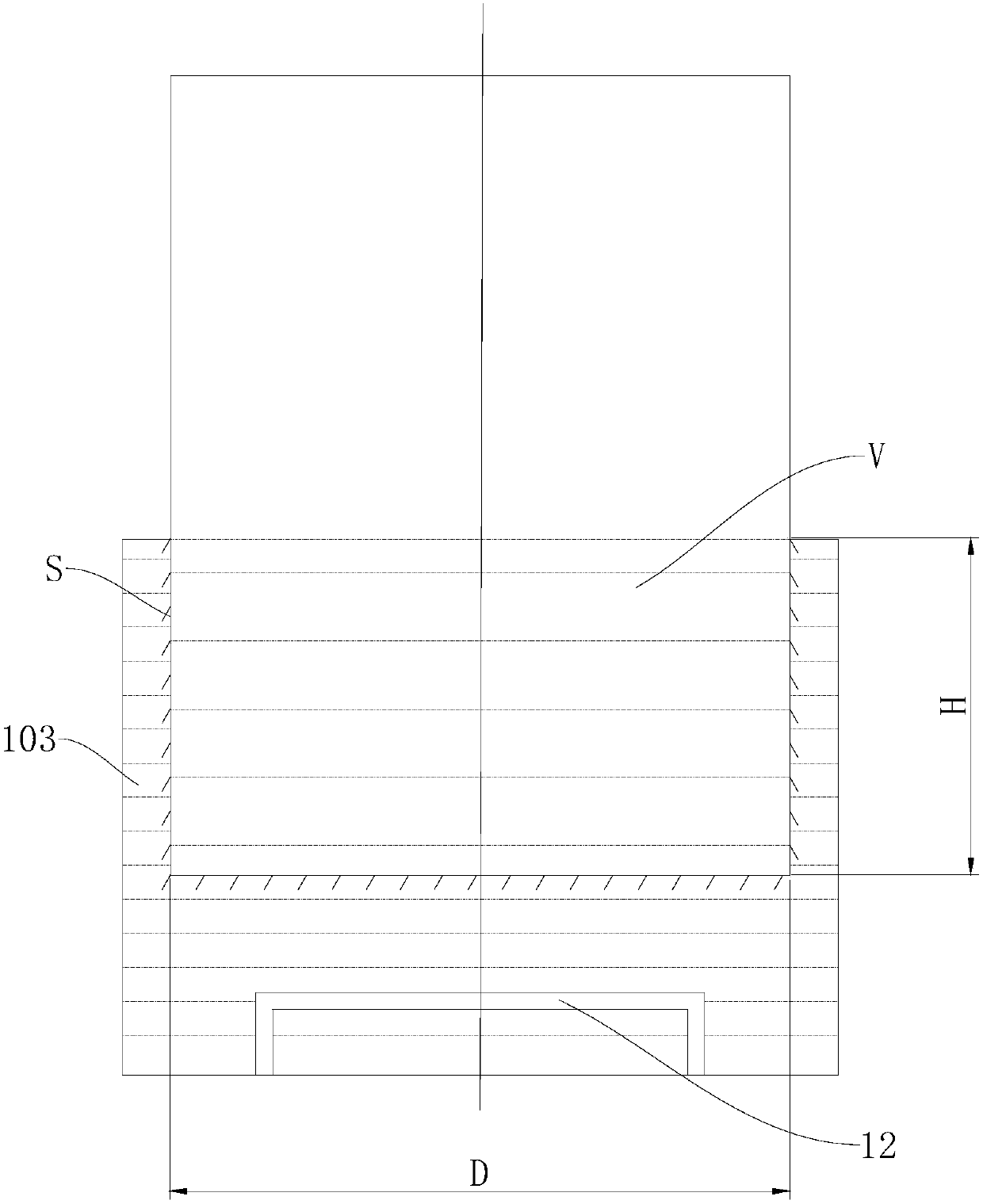

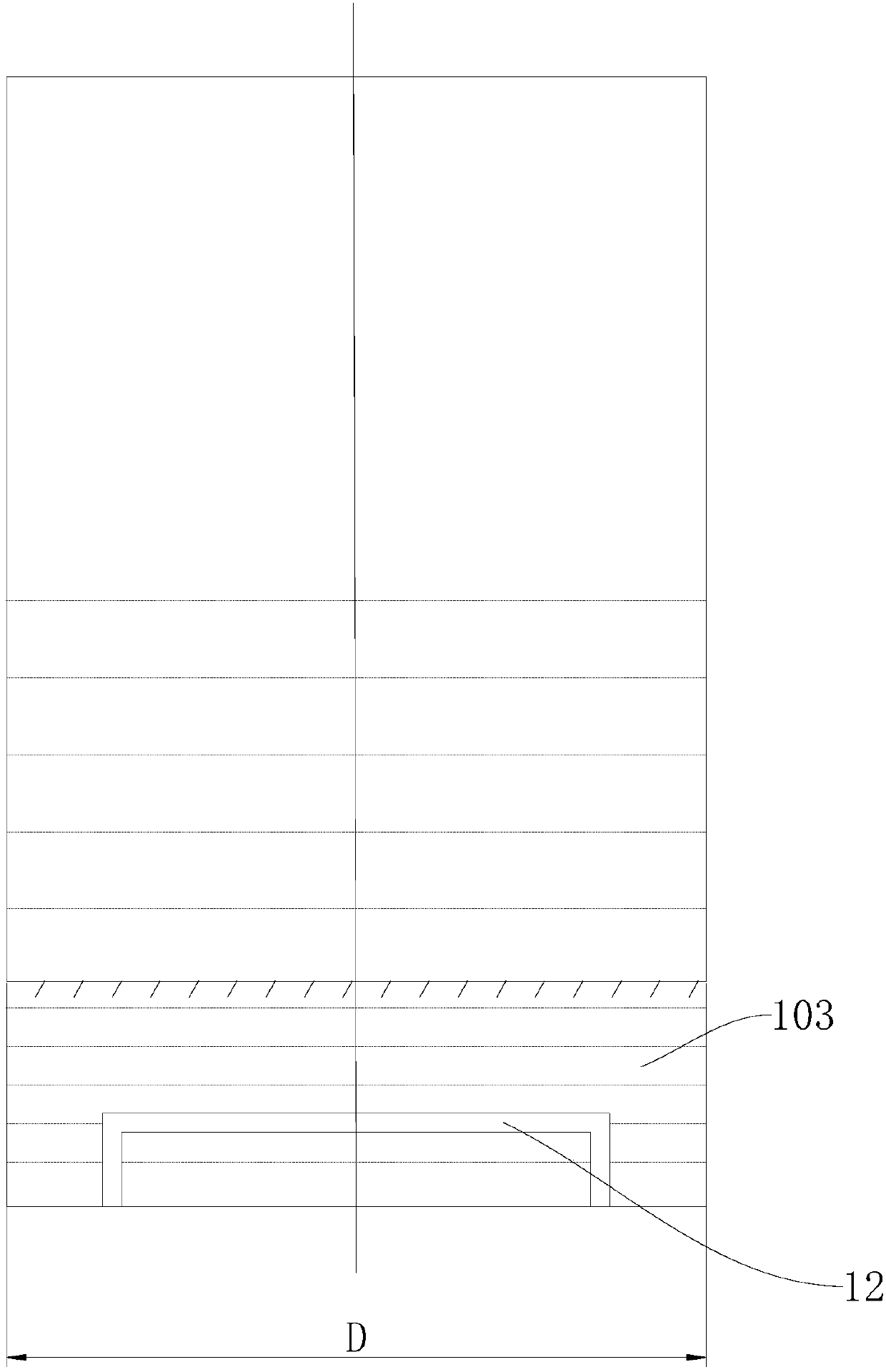

[0040] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0041] Food processors mostly use heating elements on the bottom / outer wall of the cup to conduct the heat of the heating element into the cup, although in this structure, metal elements with faster heat conduction (such as Aluminum), so as to increase the heat conduction area and avoid excessive heat concentration. However, the above-mentioned method can only improve the over-concentration of heat, but cannot fundamentally solve the problems of heat concentration and uneven conduction. Some also adopt electromagnetic heating, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com