Preparation method of self-focusing lens

A technology of self-focusing lens and lens, which is applied in the direction of lens, ion implantation plating, coating, etc., and can solve the problems of complex production process of self-focusing lens and difficult control of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to an embodiment of the present application, a method for preparing a self-focusing lens is provided, which may include:

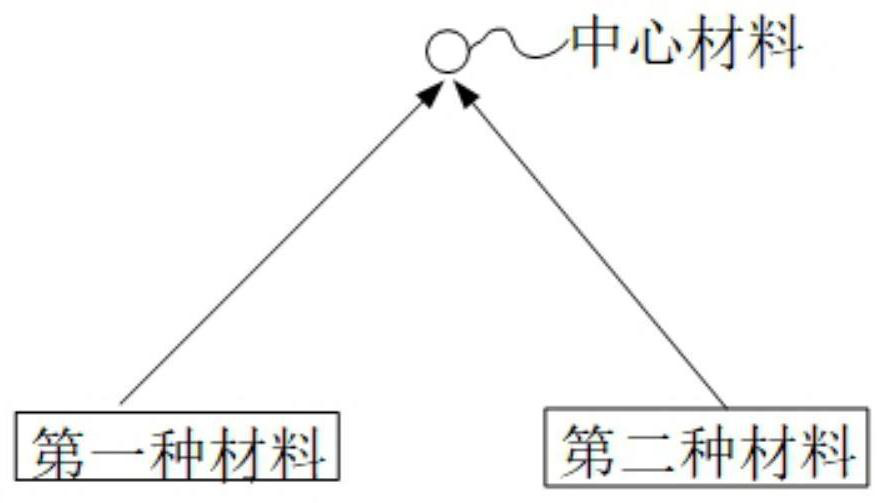

[0040] Use the index of refraction n 1 The first material is made into a central material. Preferably, the central material can be made into an elongated optical fiber with a diameter d ranging from 30 to 50 microns. More preferably, the central material can be made into a thin optical fiber with a diameter of 50 microns. long optical fiber;

[0041] Rotate the center material, preferably, the center material can be rotated at a constant speed;

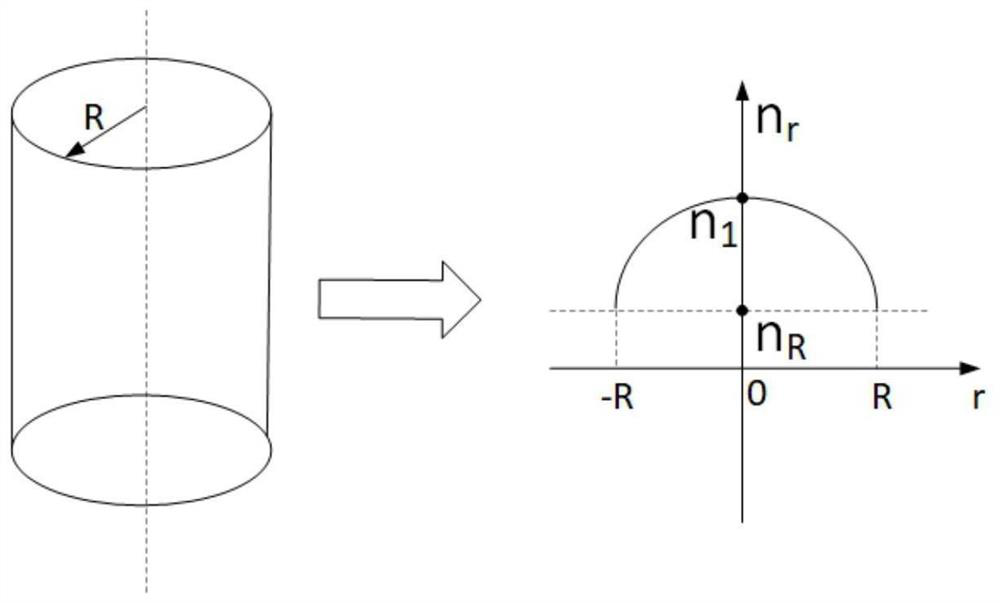

[0042] Simultaneously sputter-deposit the first material and the refractive index n towards the center material 2, and control the sputtering deposition rate of the first material and the sputtering deposition rate of the second material respectively, so that when the radius of the lens reaches the target radius R, the radial refractive index n of the lens r for where r∈[0,R] and A is the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com