Preparing process of hypoxia large particle special molybdenum powder special for LCD

A technology of special molybdenum powder and large particle size, which is applied in the field of producing special molybdenum powder with low oxygen and large particle size for LCD, which can solve the problems that the performance indicators cannot meet the requirements, and achieve easy control of the production process, simple operation, and high tap density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

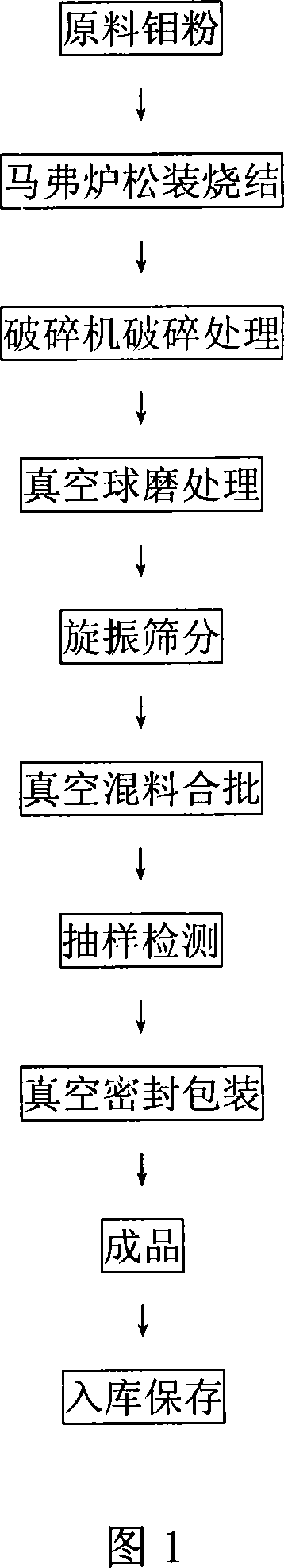

Image

Examples

Embodiment

[0028] Take 100kg of molybdenum powder that meets the requirements of MP-1 in the Q / JDC013-2002 standard for use, the average Fischer particle size is 3.50μm, and the bulk density is 1.04g / cm 3 , The chemical content index is in line with the enterprise standard. According to the process requirements, firstly heat up the muffle furnace, raise the temperature to 1350°C according to the process and keep it warm; the amount of molybdenum powder loaded in each material boat is 5Kg, and push 2 boats into the muffle every 30 minutes according to the set process In the furnace, the operation is carried out by continuously pushing and discharging materials; after the molybdenum powder released from the furnace after reduction is discharged, it is crushed in the jaw crusher, and N2 gas must be fed into the crusher for protection during crushing; The molybdenum block is sent into the vacuum ball mill through the feeding mechanism, the ball-to-material ratio is set to 2:1, the ball milli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com