A production system and production method of energy-saving and environment-friendly fiber cement building materials

A technology of fiber cement, energy saving and environmental protection, applied in auxiliary molding equipment, supply devices, ceramic molding machines, etc., can solve the problems of lack of surface decoration, poor heat insulation effect, single fiber cement layer, etc., to achieve intelligence and automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

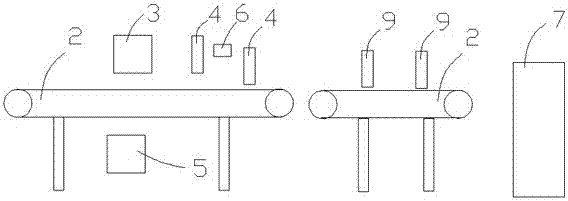

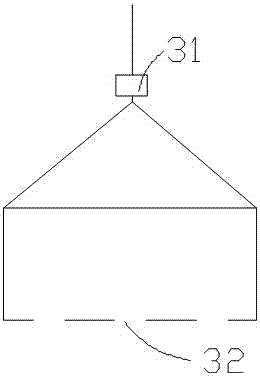

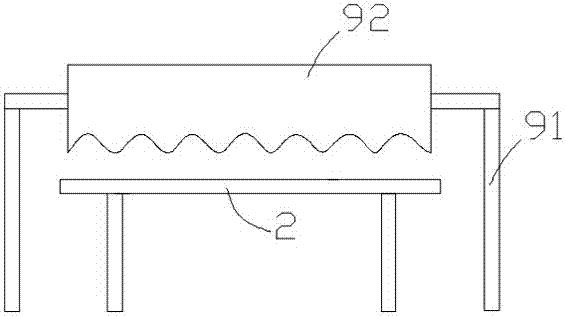

[0038] Such as Figure 1~3 As shown, this embodiment takes the generation of fiber cement wave tiles as an example. An energy-saving and environmentally friendly fiber cement wave tile production system, including a conveying platform for transporting fiber cement wave tiles 2, a feeding device for adding materials to the fiber cement wave tiles, and a scraper for smoothing the material on the fiber cement wave tiles. Flattening device 4. Forming device 9 and controller 5 for processing the fiber cement corrugated tile into corrugated shape after leveling; along the conveying direction of the conveying platform 2, a feeding device 3 and a scraper are sequentially arranged above the conveying platform 2 The leveling device 4 and the shaper 9; the controller 5 is in communication connection with the conveying platform 2, the feeding device 3, the leveling device 4 and the shaper 9.

[0039] In this implementation, the conveyor platform 2, the feeding device 3, the leveling device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com