Floatation method of whole grade ilmenite

A full-grain grade, ilmenite technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the difficult control of ilmenite grade fluctuation, low recovery rate of ilmenite metal, and poor operating environment for employees and other issues, to achieve the effect of reducing production and operation costs, low production costs, and short processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

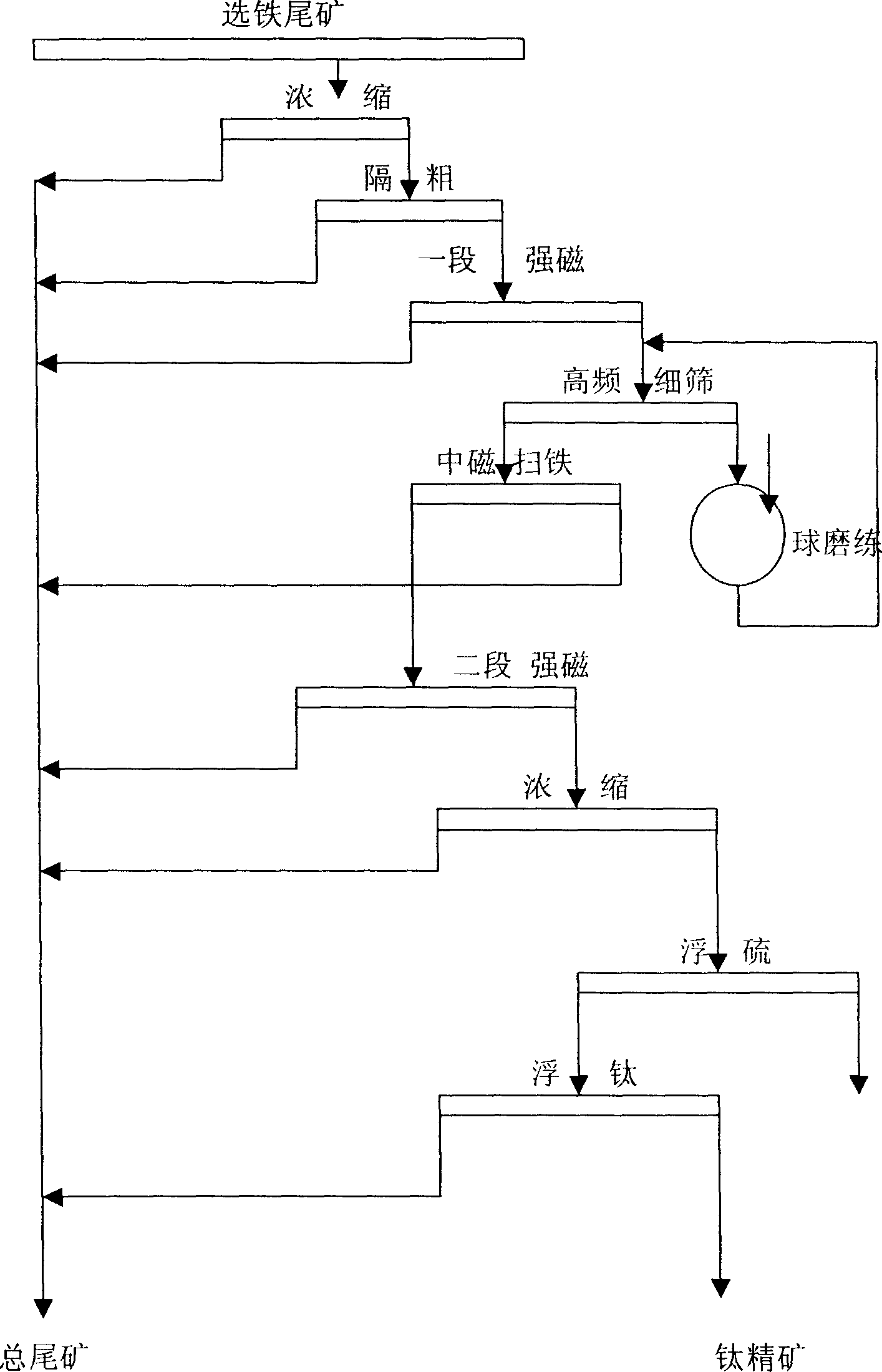

[0019] see figure 1 , the new method flow process of ilmenite sorting of the present invention is:

[0020] 1. Use the tailings after iron separation of vanadium-titanium magnetite as raw material (TFe10-13%, βTiO 2 11~13%), after a strong magnetic field (Slonφ1750), the magnetic field strength is 1300 amps, and titanium βTiO can be obtained after throwing the tail 2 17-19% crude titanium concentrate;

[0021] 2. The coarse titanium ore is subjected to one-stage closed-circuit grinding (one φ2721 grid-type ball mill, two high-frequency fine screens), and the qualified products pass through the weak magnetic iron sweep, and then enter the second-stage strong magnetic field (Slonφ1750) with a magnetic field strength of 750 amps. Obtain βTiO 2 22-24% titanium concentrate;

[0022] 3. After the reverse flotation desulfurization operation (the main agent is xanthate), the tailings of the desulfurization operation enter into the full-size floating titanium operation, and the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com