Flexible first-time sand control sandblasting technique pipe

A process string and sand control technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of multiple sand washing, easy blocking and other problems, so as to reduce the cost of sand control, improve the time efficiency of sand control, improve The effect of one-time success rate of sand control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

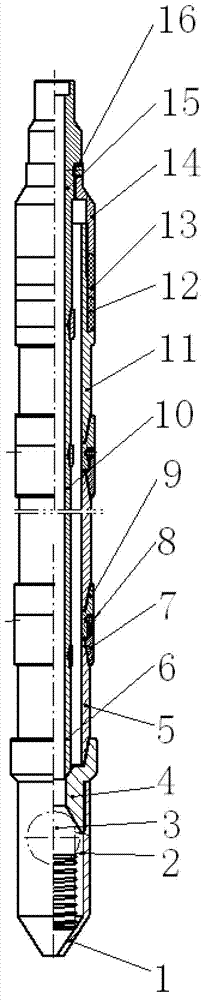

[0008] Such as figure 1 As shown, a flexible sand control and sand flushing primary process string includes a plurality of slotted screens; the plurality of slotted screens are connected by flexible connectors to form a slotted screen string 5, and the flexible connector includes a flexible connection The lower joint 7 of the device and the upper joint 9 of the flexible connector, the lower joint 7 of the flexible connector and the upper joint 9 of the flexible connector are connected and locked by the locking screw 8 of the flexible connector, and the lower end of the slotted screen string 5 is connected to the ball seat 4 , the lower end of the ball seat 4 is connected to the shoe nib 1, the upper end of the slotted screen tube string 5 is connected to the hanger main body 11 through a flexible connector, the hanger main body 11 is equipped with a hanger sealing rubber tube 12 and a rubber tube spacer ring 13, and the rubber tube is compressed The joint 14 is placed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com