Crankshaft box balancing bearing cover oil passage steel ball press fitting tool

A technology of press-fitting tooling and bearing caps, which is applied in the direction of manufacturing tools, workpiece clamping devices, hand-held tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

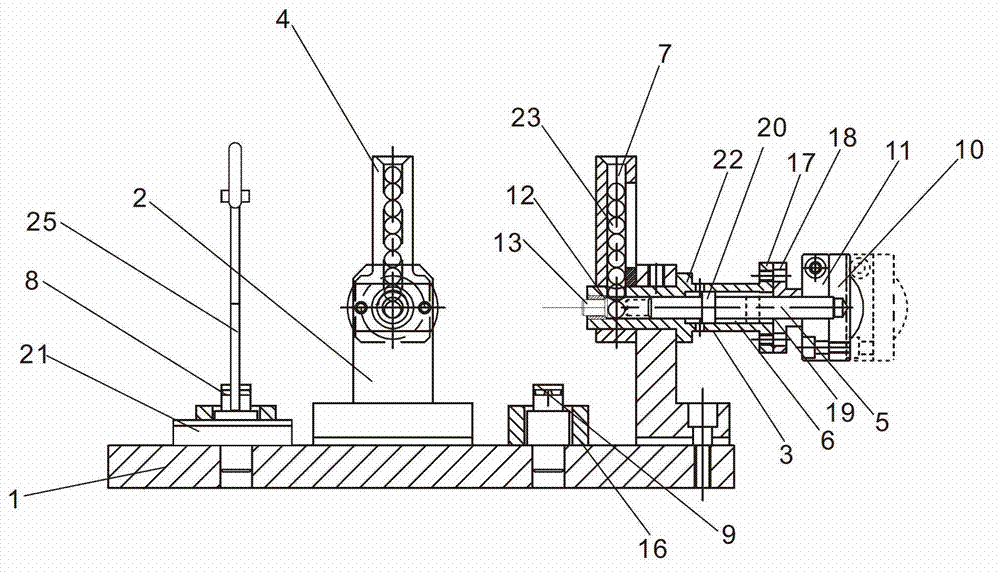

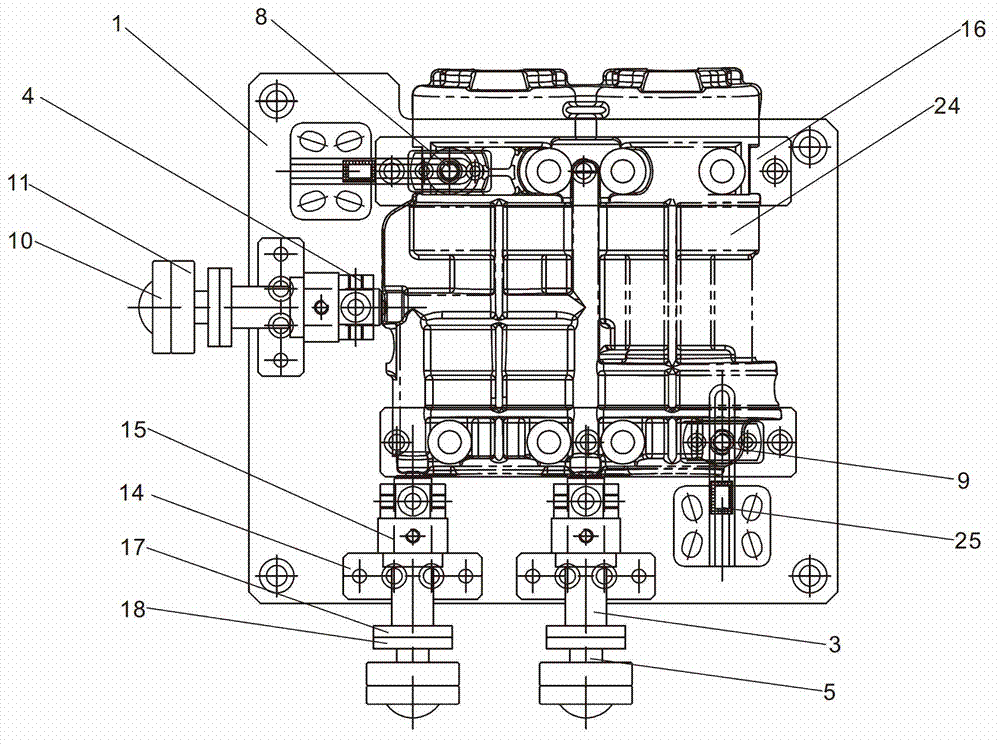

[0024] Such as figure 1 and figure 2As shown, a crankcase balance bearing cap oil passage steel ball press-fitting tool is used to press the oil passage steel ball for the crankcase balance bearing cap with three oil passages. The crankcase balance bearing cap oil passage steel ball The press-fit tooling includes a rectangular bottom plate 1, on which a steel ball press-fit mechanism and a balance bearing cap positioning mechanism are arranged, and the steel ball press-fit mechanism includes a support 2, a steel ball guide sleeve 3, a steel ball bin 4 and The steel ball pressing rod 5, the support 2 is fixed on the bottom plate 1, the steel ball guide sleeve 3 is arranged on the support 2, the steel ball guide sleeve 3 is provided with a guide sleeve pipe 6 with openings at both ends, and the guide sleeve pipe 6 The diameter is less than twice the diameter of the steel ball in the oil passage of the balance bearing cover and greater than the diameter of the steel bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com