Preparation method of iron oxide brown

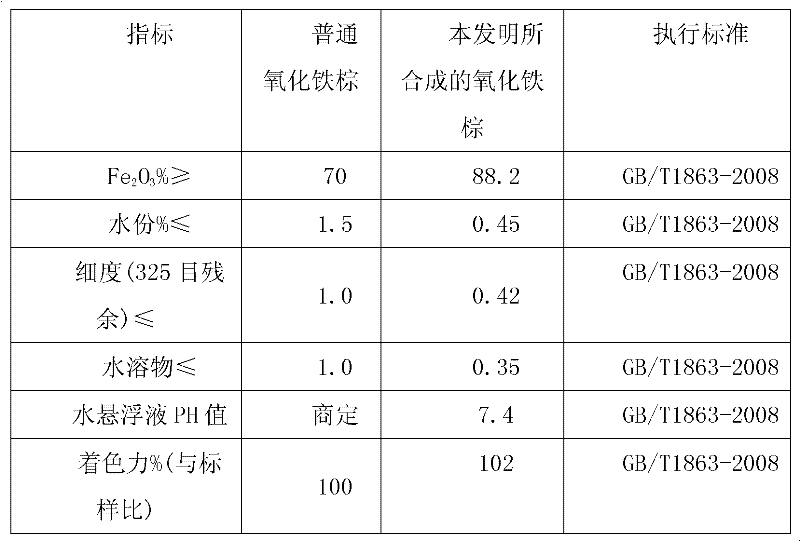

An iron oxide brown and oxygen technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of unstable product quality and uneven hue, and achieve the effects of convenient operation, pure shade and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A kind of preparation method of iron oxide brown, it is characterized in that: comprise the following steps:

[0021] (1), in the reaction kettle, the ferrous sulfate solution with the concentration of 38-42% and the liquid caustic soda with the concentration of 40-45% are mixed into a slurry in a mass ratio of 1: 0.25-0.3, and water is added to make the slurry The concentration is adjusted to 10-12%, and the temperature is raised to 80-85°C;

[0022] (2), slowly add sodium nitrite according to the ratio of 36KG per ton of product input, and feed oxygen at the same time, and then open the spray equipment to fully mix the slurry, oxygen and the NO produced in the reaction process;

[0023] (3) During the reaction process, keep sampling and comparing with the standard sample, the color of the product is similar to that of the standard sample with yellow-brown or reddish-brown shade, and then stop the reaction, and the taken out slurry is filtered, washed, dried, and broke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com