Anti-oxidation single component aromatic hydrocarbon solvent used in copper phthalocyanine synthesis

An aromatic solvent, oxidation-resistant technology, applied in organic chemistry, chemical instruments and methods, porphine/acridine porphine, etc., can solve the problem of unstable copper phthalocyanine quality and yield, affecting the use range of copper phthalocyanine, and color deviation Green phase and other problems, to achieve the effect of promoting environmental protection, good oxidation resistance, high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

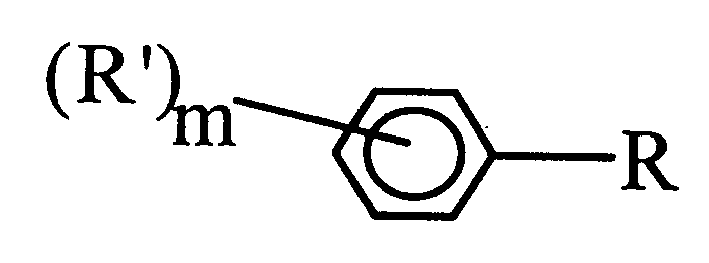

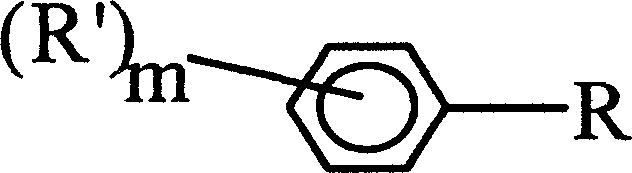

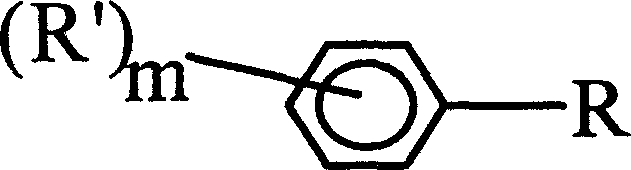

Image

Examples

Embodiment 1

[0021] In a glass reactor with a volume of 2 liters, add 1000 parts of raw material ethylbenzene (purity ≥ 99%), 650 parts of catalyst concentrated sulfuric acid, stir and cool to below 20 ° C, and put 700 parts of isobutylene (purity ≥ 99%) through dehydration. %), is passed into the reactor from the bottom of the reactor, and during the passage, the reaction temperature is kept at about 30°C. When the amount of monoolefin feed is close to the specified amount, samples are taken from the reactor at any time for GC (gas chromatography) Analysis, when the content of the finished product in the reaction mixture reaches the requirements, stop the reaction, separate and recover the catalyst, and use it for the next batch of synthesis. The product obtained by the separation is purified to obtain about 1335 parts of the crude product solvent, and the content is about 90%; Purified by distillation to obtain 1197 parts of aromatic hydrocarbon solvent compound A, with a content of 98.8-...

Embodiment 2

[0024] In a glass reactor with a volume of 2 liters, add 1000 parts of raw material ethylbenzene (purity ≥ 99%), 150 parts of catalyst anhydrous aluminum trichloride (purity ≥ 97%), stir and cool to below 10°C, and 750 parts of isobutylene (purity ≥ 99%) dehydrated are passed into the reactor from the bottom of the reactor. During the passage, the reaction temperature is kept at 5-10°C. When the amount of single-bond olefin is close to the specified amount, Sampling from the reactor at any time for GC analysis, when the content of the finished product in the reaction mixture reaches the requirements, stop the reaction, separate and recover the catalyst, and use it for the next batch of synthesis. The product obtained from the separation is purified to obtain about 1260 parts of the crude product solvent. The content is about 90%; the crude product is purified by rectification to obtain 1130 parts of pure solvent, the content is 98.2-98.5%, and the yield is 85.3-86.4%; its infra...

Embodiment 3

[0026] According to the same method as in Example 1, the content of aromatic hydrocarbon solvent compound B obtained by synthesis is 98.6~99.3%, the yield is 89~93%, and its infrared absorption characteristic peak is: 3000~2800cm -1 , 1600~1500cm -1 , 900~800cm -1 ;Product appearance: white and transparent water, density 0.875, boiling range 210-216°C, refractive index (n 11 ) 1.5046.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com