Dyeing and finishing process for Chinese velvet

A process and dye vat technology, applied in the field of dyeing and finishing of Chinese wool, can solve the problems of energy and water consumption, sewage discharge, etc., and achieve the effect of reducing water consumption, reducing sewage discharge, and pure color and light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

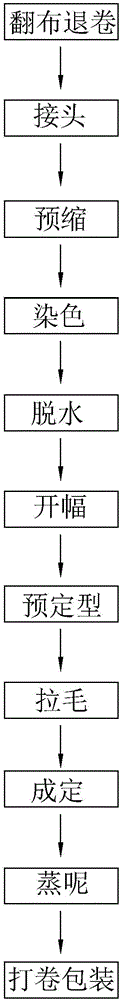

[0040] The present invention will be further described with reference to the accompanying drawings.

[0041] The fabric is woven by warp and weft, warp 250DSTY; weft 26ST / R (8020) yarn + 70D spandex.

[0042] The dyeing and finishing process of the fabric is as follows;

[0043] 1. Use the fabric turning machine and unwinding machine to turn and unwind the fabric;

[0044] 2. Joint the fabric with a sewing machine;

[0045] 3. Use a pre-shrinker to pre-shrink the fabric to adjust the width of the fabric to 152cm. The pre-shrinker is equipped with three ovens through which the fabric passes sequentially. The temperature of the first steam box is 60°C, and the temperature of the second steam box is 80°C. ℃, the temperature of the third steam box is 90 ℃, and the cloth feeding speed of the pre-shrinker is 45M / min;

[0046] 4. Dye the fabric with a dyeing tank. The dyeing agent in the dyeing tank includes disperse dyes, blended dyes, PE-400 refining and dyeing one-bath leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com