Patents

Literature

36results about How to "Fully stereotyped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

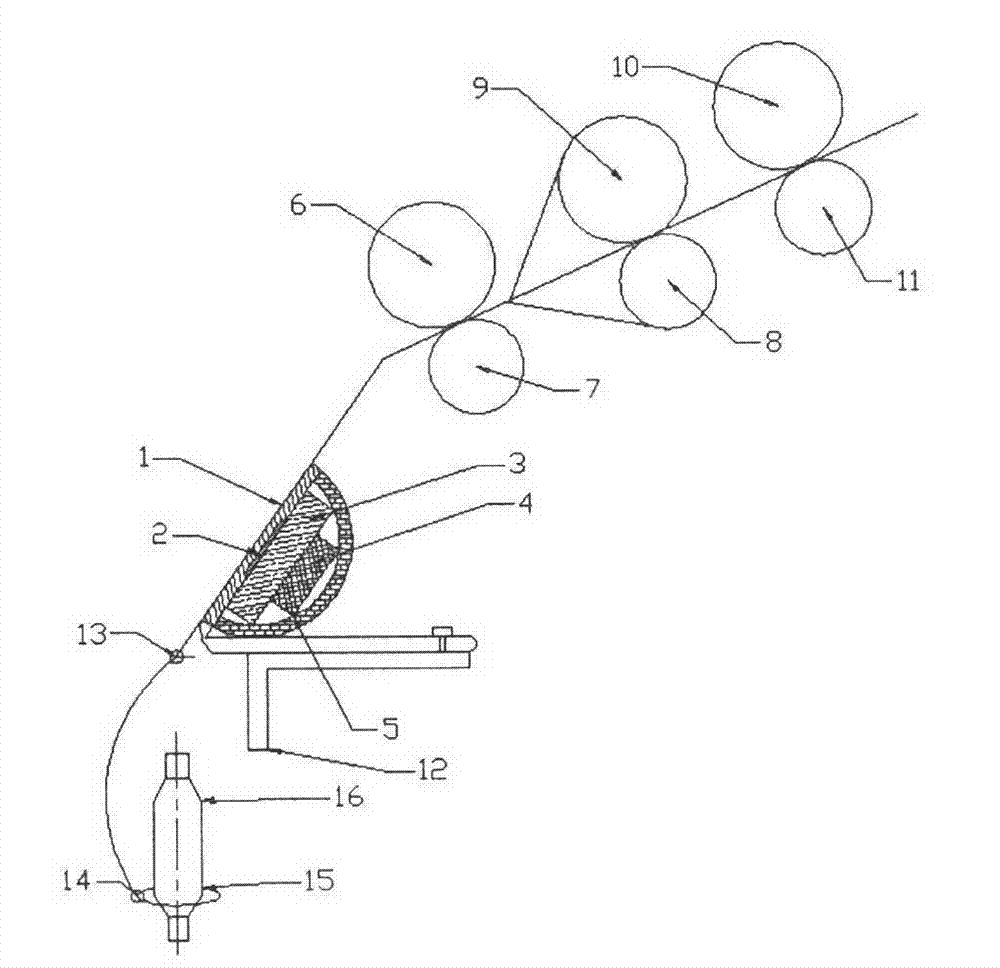

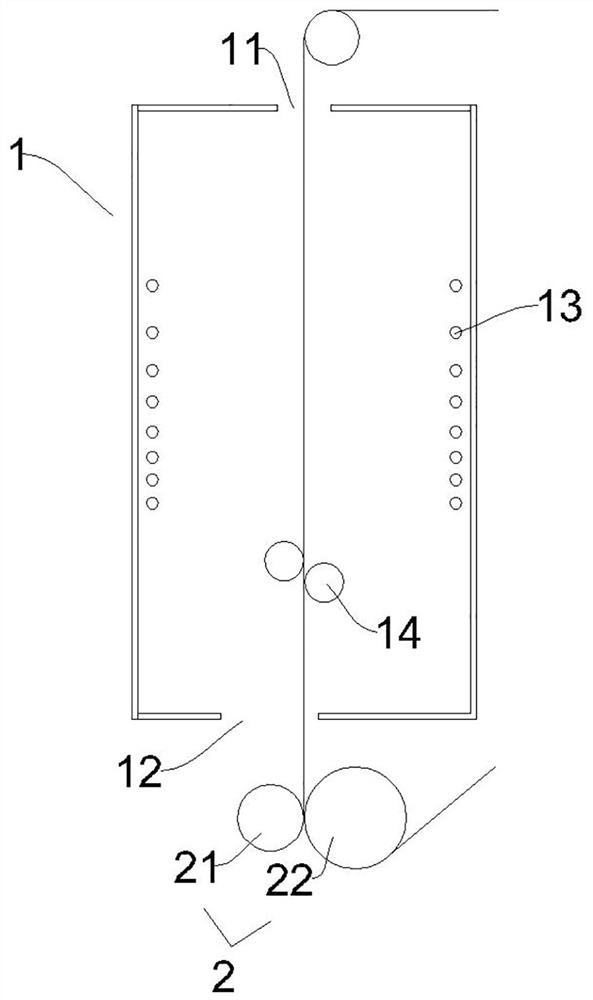

Method for producing warp knitting coral velvet polyester filament yarn

InactiveCN101476188AAdjustable fine structureFine structure stabilityTextiles and paperHot boxEngineering

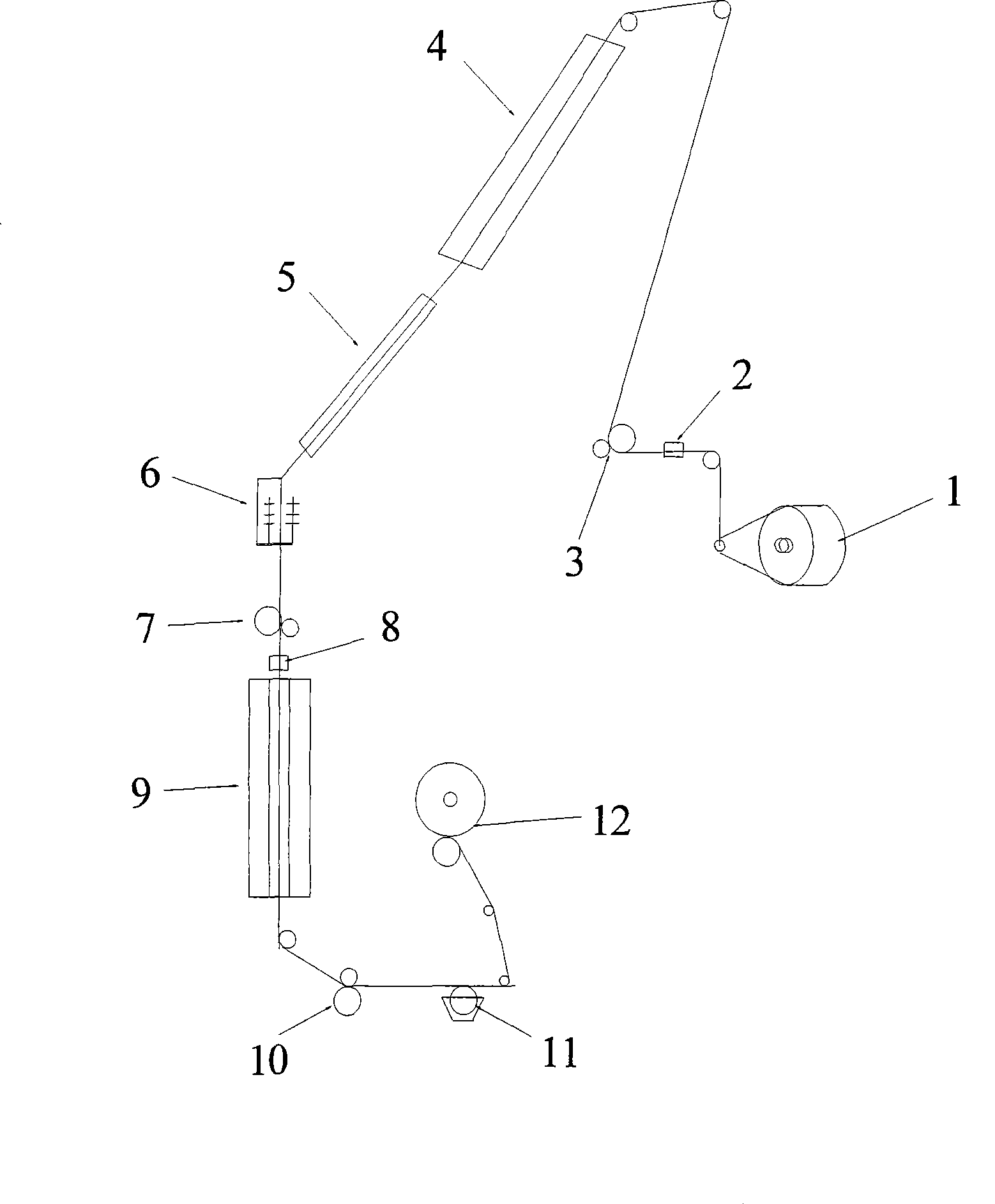

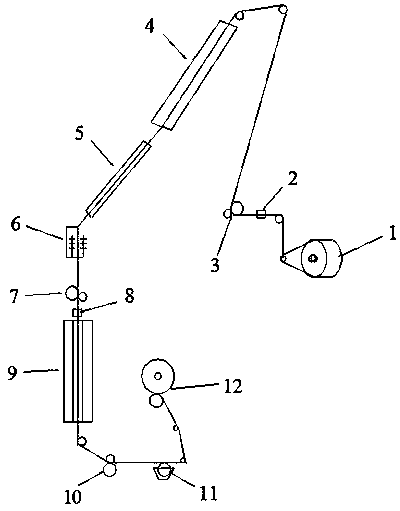

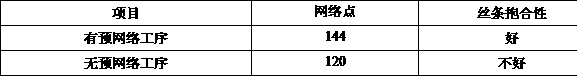

The invention provides a method for producing warp knitting coralon leather polyester filament. The processed POY protofilament is removed to false twist after being detected and balanced, the process flow is that: POY protofilament - a roller feeding in - a hot box for heating distortion - cooling - false twist - two rollers feeding in - two hot boxes for heating and forming - three rollers feeding out - oiling - DTY winding forming, a pre-network working procedure is added between the ROY protofilament and a roller feeding in. The method solves problem that coralon leather fabric processed by normal polyester has defects of no-soft hand touch, adhesive hair, down pile making, without coralon leather style, and can cover the prior art shortage.

Owner:JIANGSU HENGLI CHEM FIBER

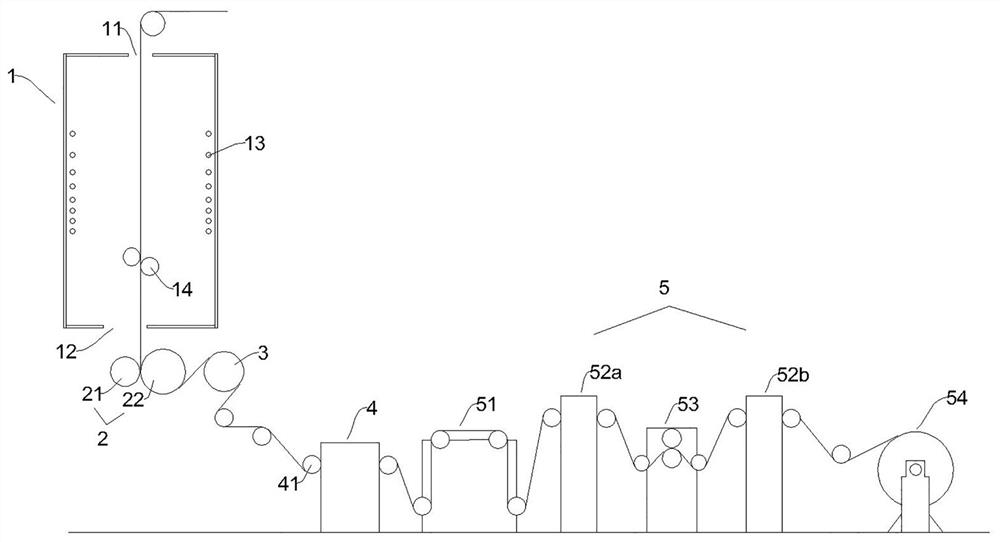

Preparation method of super-soft and super-fine polyester filament yarn

The invention discloses a preparation method of a super-soft and super-fine polyester filament yarn. The preparation method comprises the following steps: preparation of POY protofilaments, pre-interlacing, processing with a first thread feeding roller, processing with a first deformation heat box, processing with a cooling plate, processing with a false twister, processing with a second thread feeding roller, medium interlacing, processing with a second heat box, processing with a third thread feeding roller, processing with a finish application roller, winding formation of DTYs and inspection of a spinning cake. In the preparation method, the process of pre-interlacing is added between the preparation of the POY protofilaments and the step of processing with the first thread feeding roller, so that the cohesive property and the draping property of fibers can be effectively improved, the processed polyester filament yarn is upright in strands and good in bundling and is favorable fornaps of subsequently woven fabric to be upright, and the super-soft and super-fine style is met; the temperature of the second heat box is controlled to 160-180 DEG C, so that the strands are set by high temperature more fully, are not dispersed easily and do not have the phenomena of hair adhesion and nap collapse, and the style of flannel fabric is met; cotton fabric is substituted easily, so that the super-soft and super-fine polyester filament yarn has wide market prospect and remarkable economic benefit.

Owner:JIANGSU DELI CHEM FIBER CO LTD

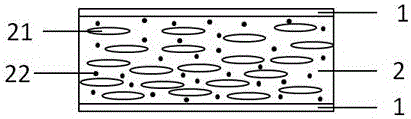

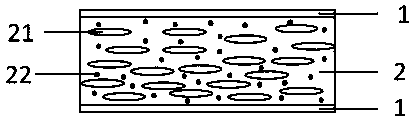

Optical reflection film with low thermal shrinkage rate, and preparation method therefor

ActiveCN106125173AInternal stress release completelyGood dimensional stabilityMirrorsSynthetic resin layered productsOptical reflectionPolyester

The invention relates to the field of polyester films, and specifically relates to an optical reflection film with a low thermal shrinkage rate, and a preparation method therefor. The reflection film comprises a reflection film main layer and an auxiliary layer on the main layer. The main layer comprises thermoplastic resin, incompatible resin, white inorganic filling particles and a nucleating agent. The auxiliary layer comprises thermoplastic polyester, an anti-adhesion agent and an antistatic agent. The reflection film is better in size stability, is excellent in flatness when being used in a backlight module group, and cannot be wrinkled because of temperature changes.

Owner:苏州盛达飞智能科技股份有限公司

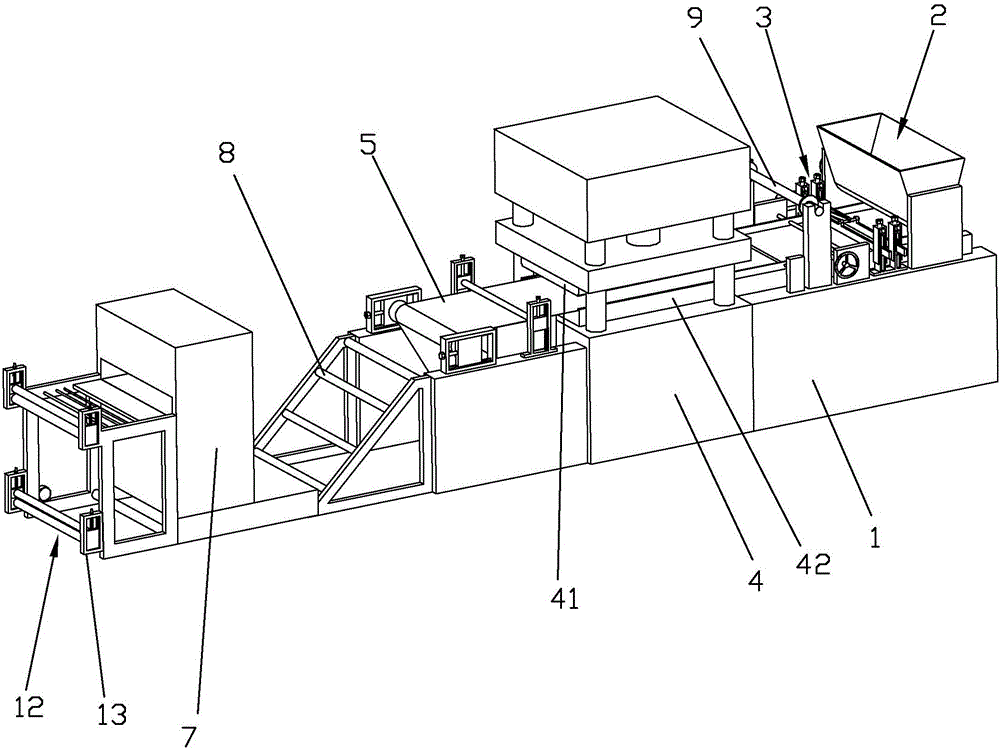

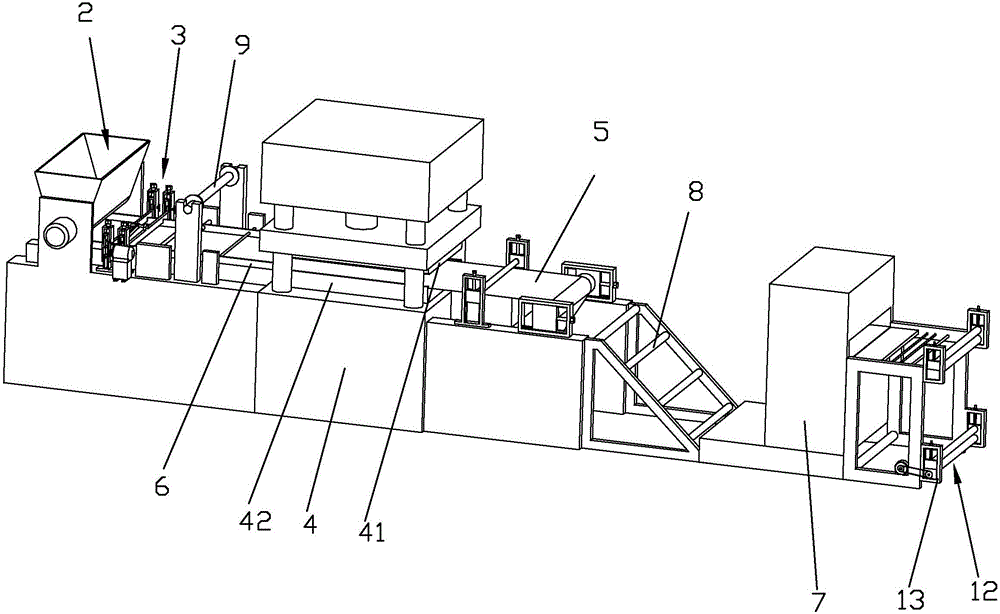

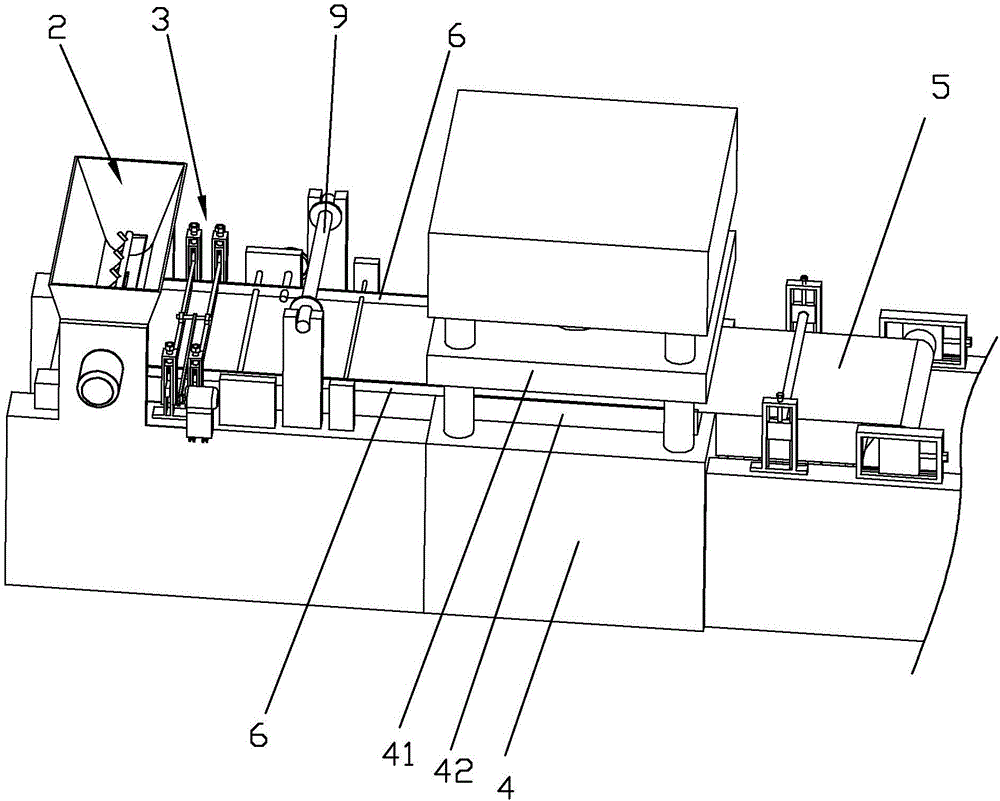

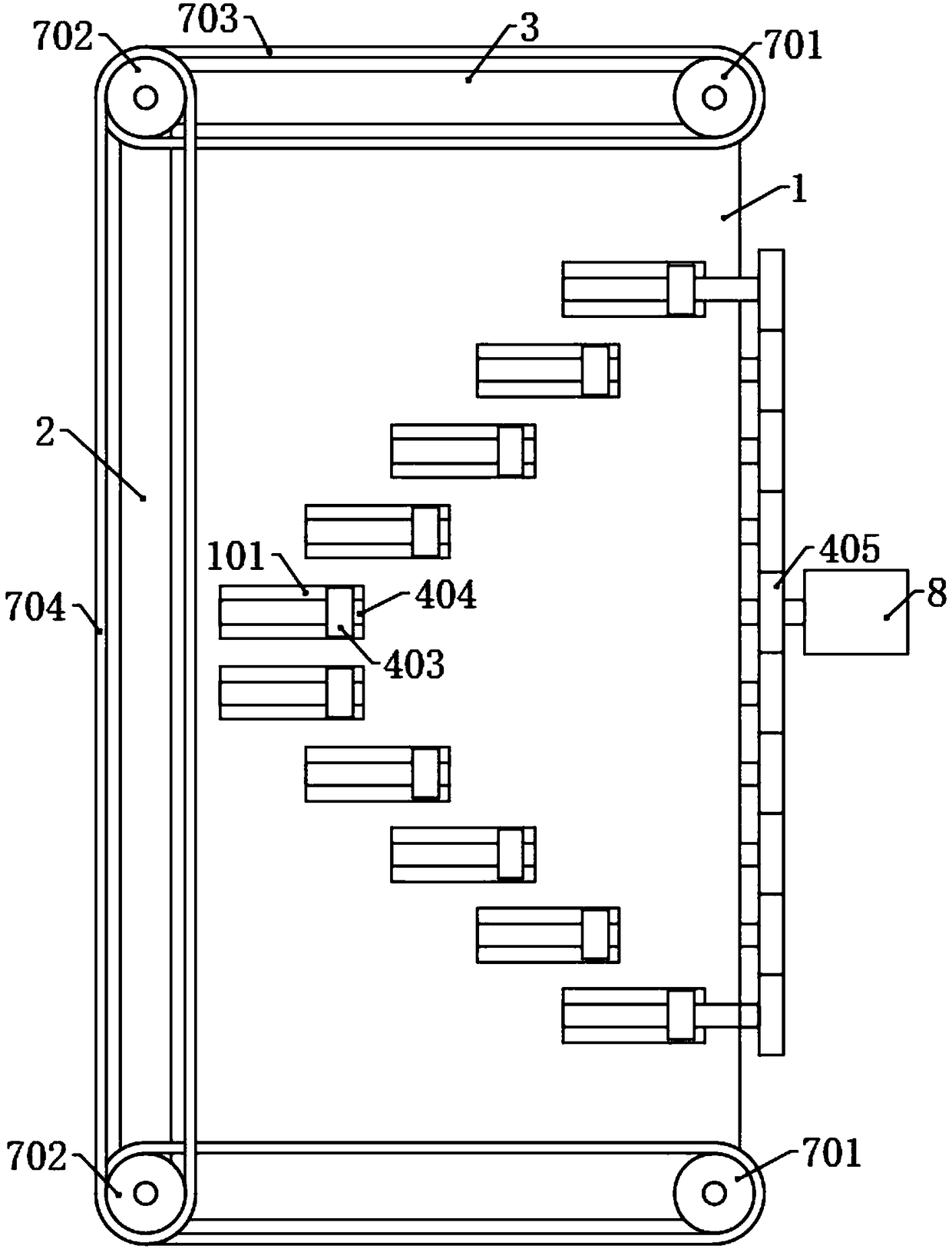

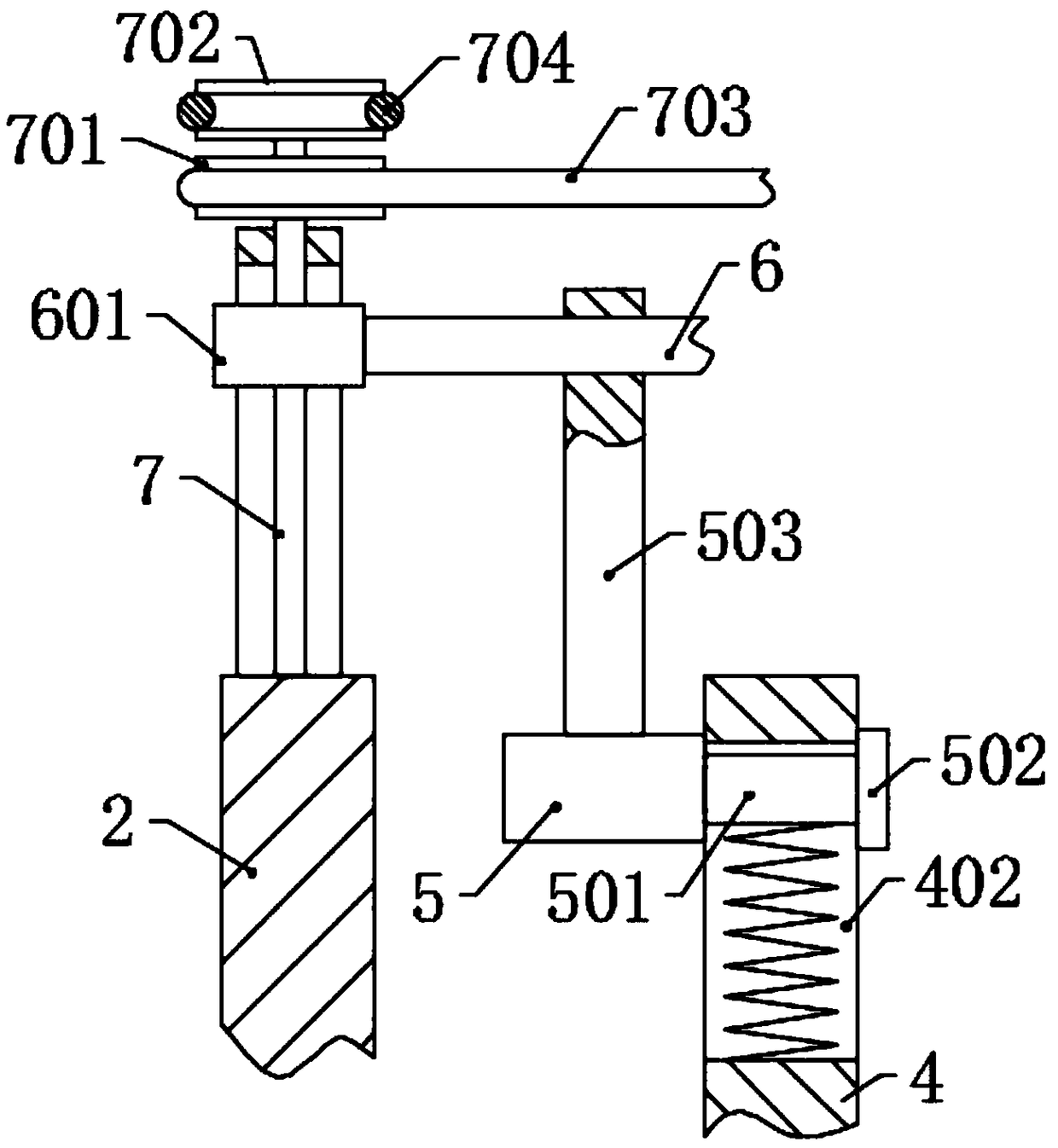

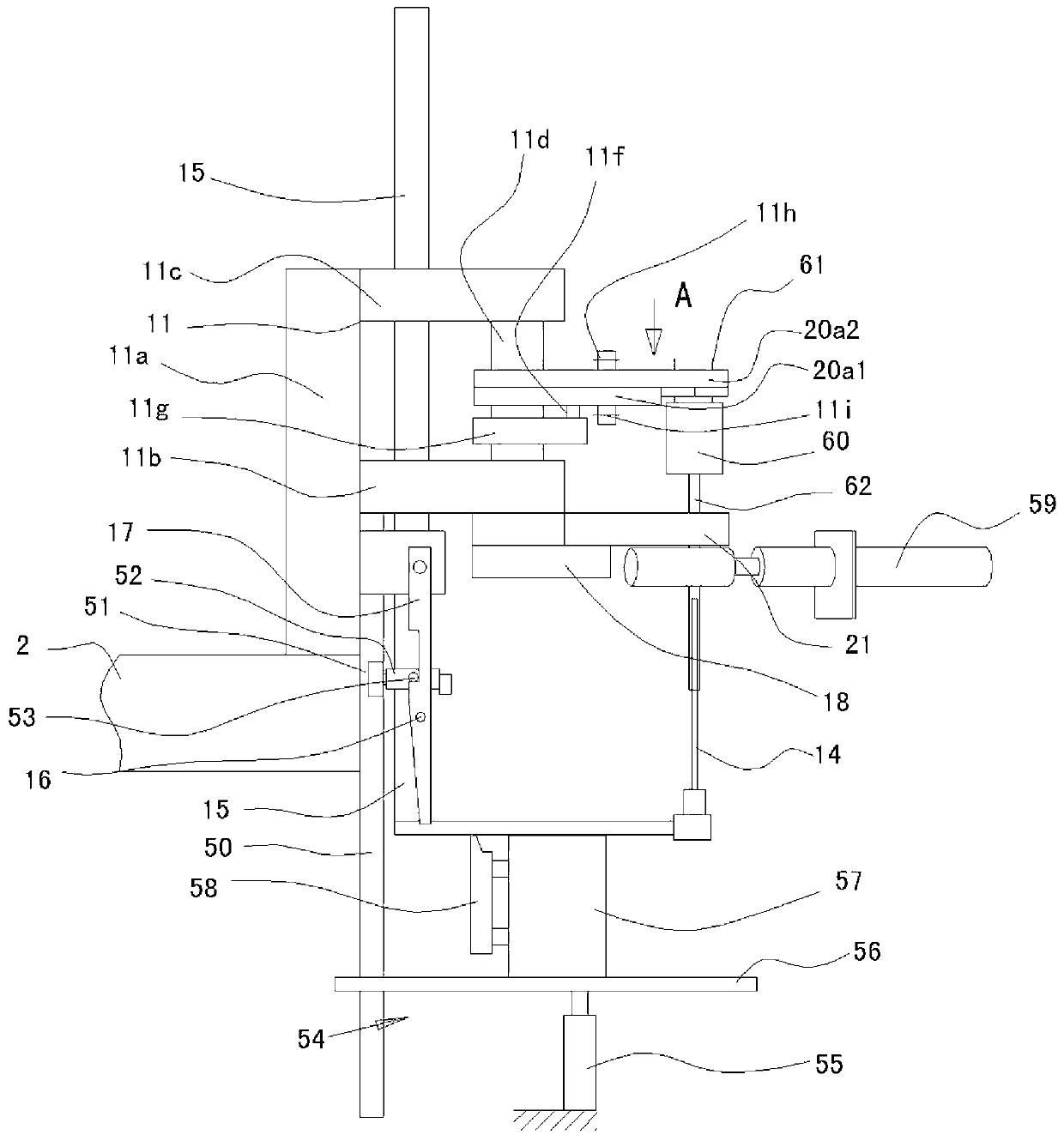

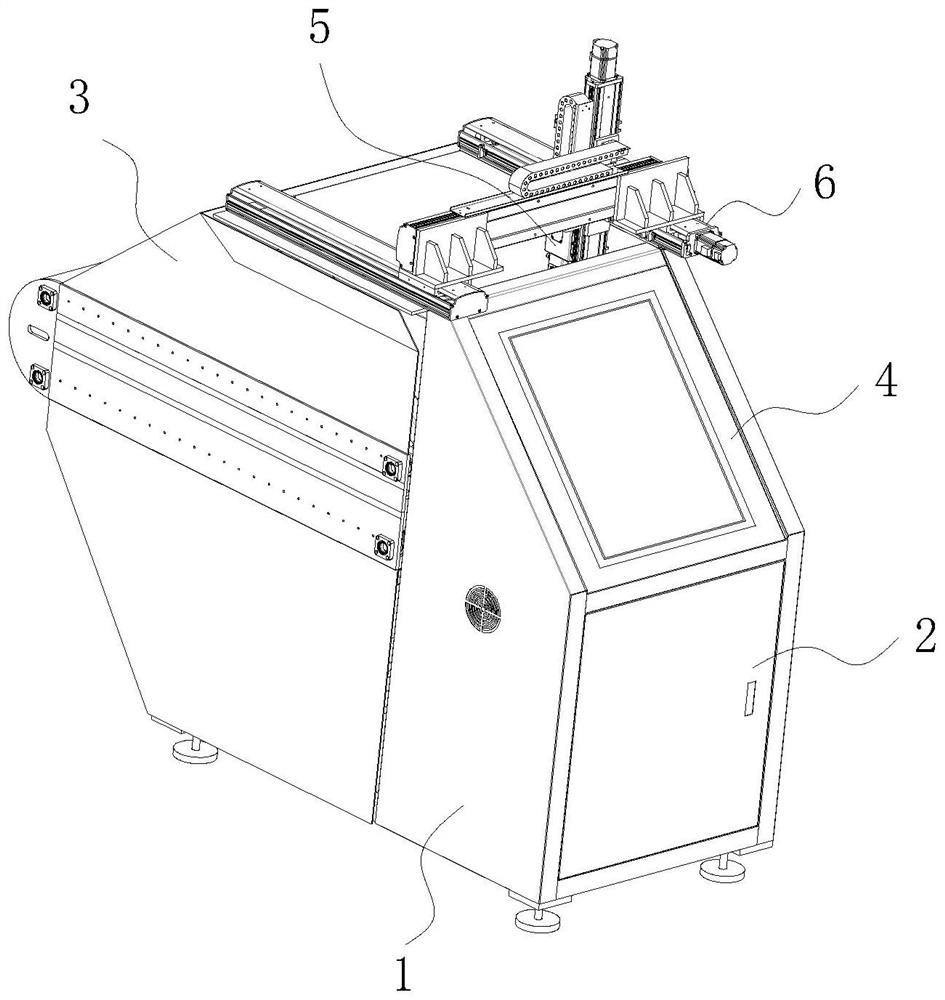

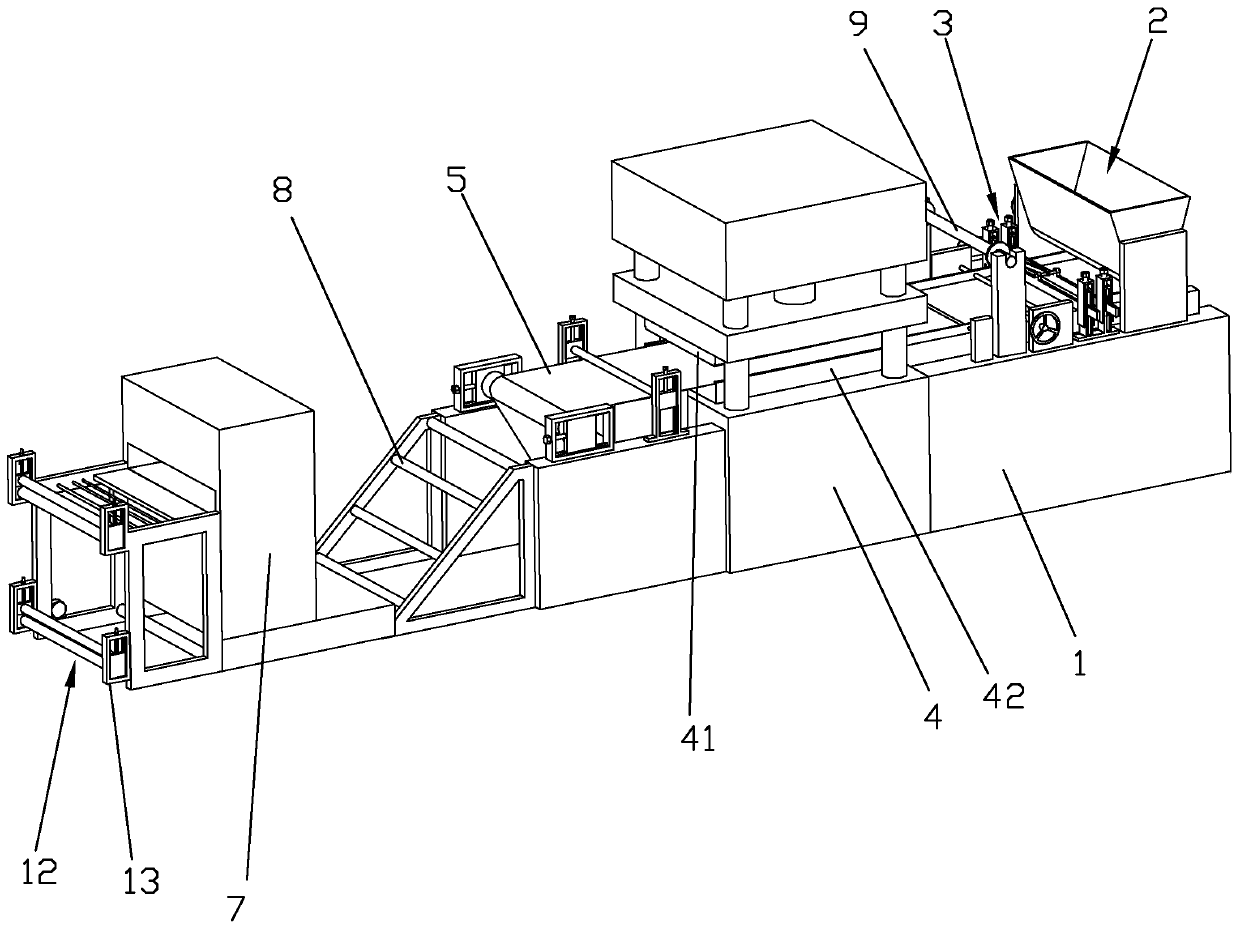

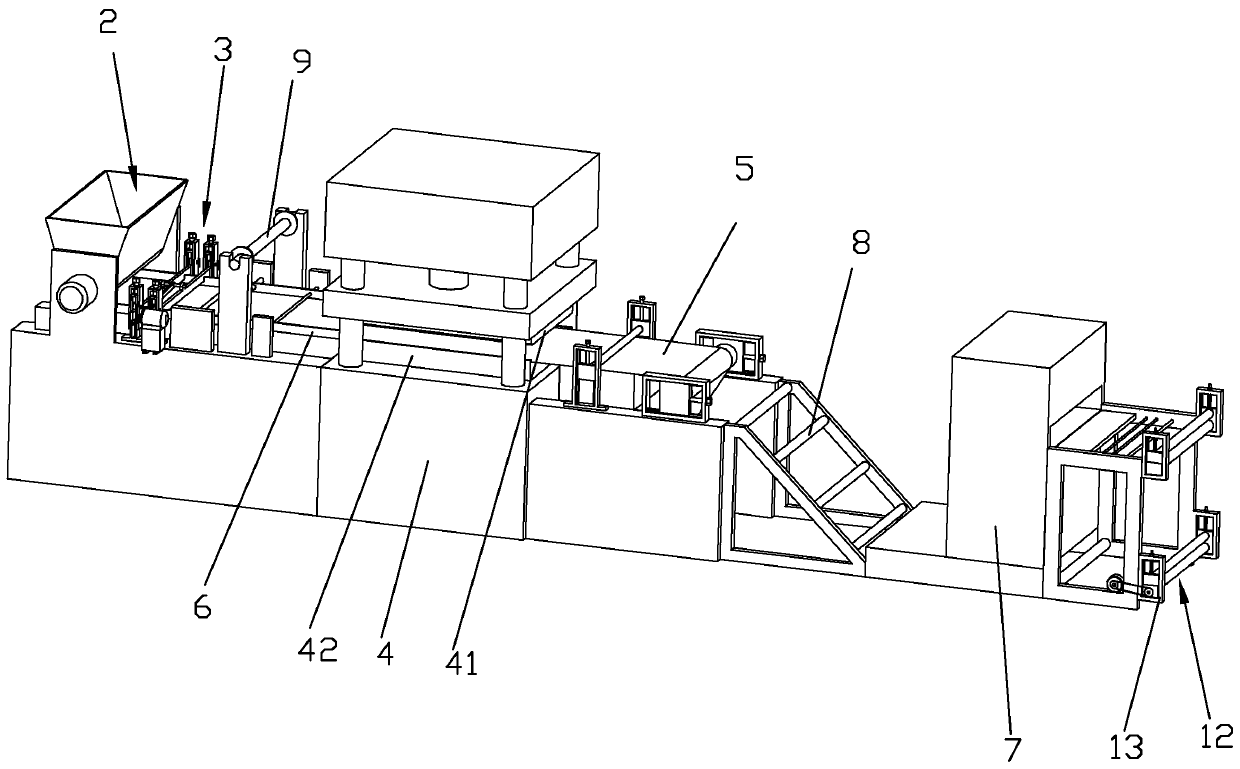

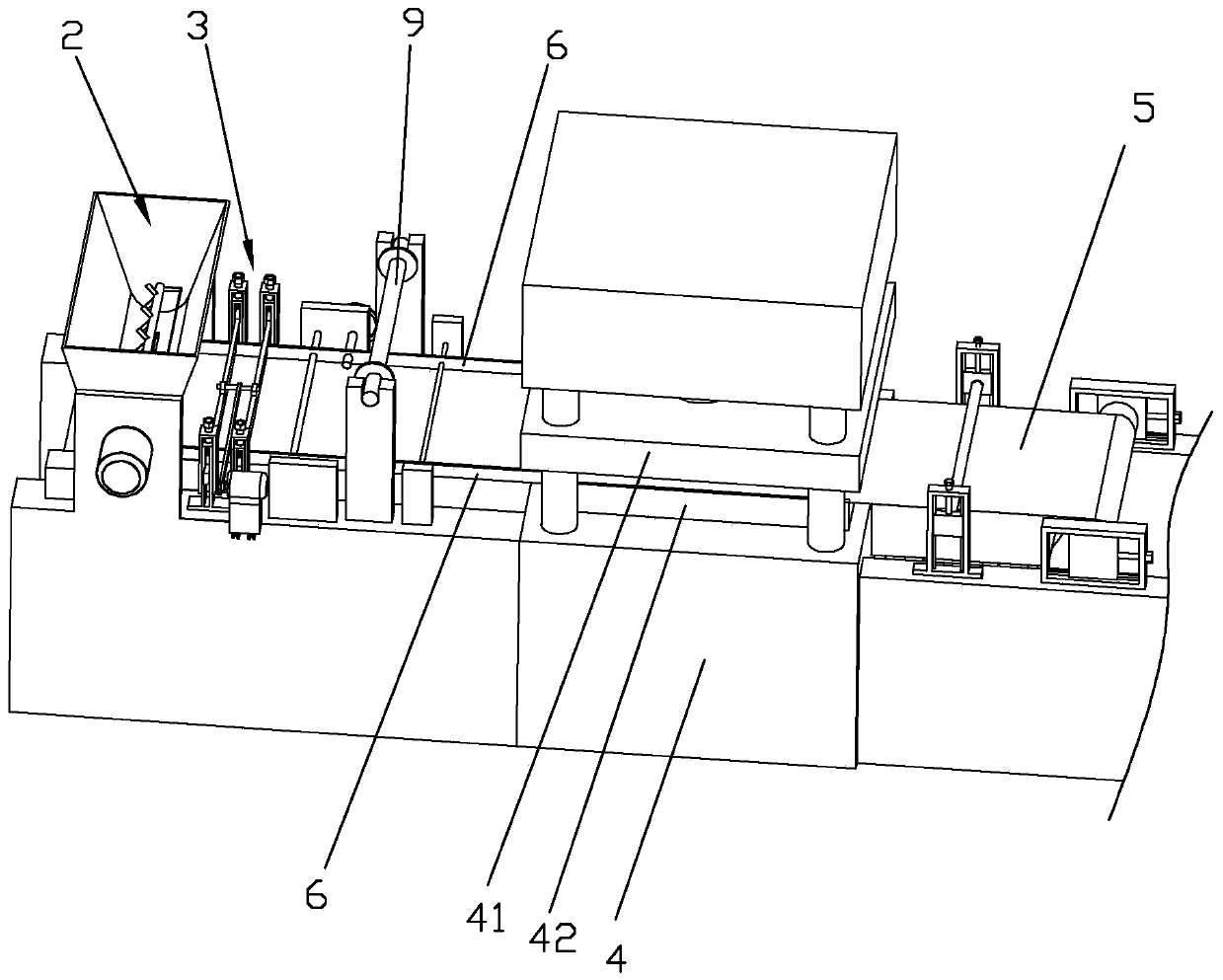

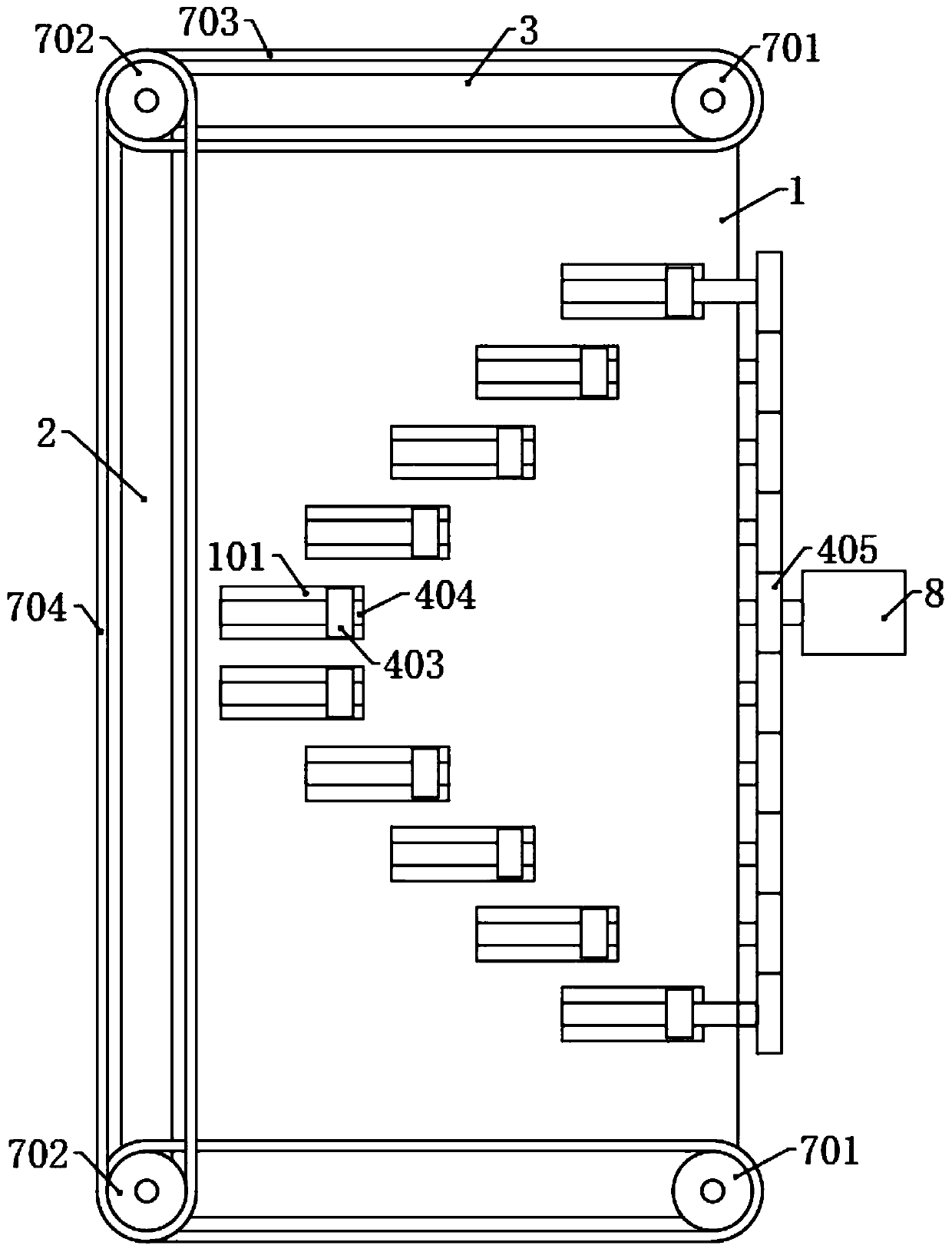

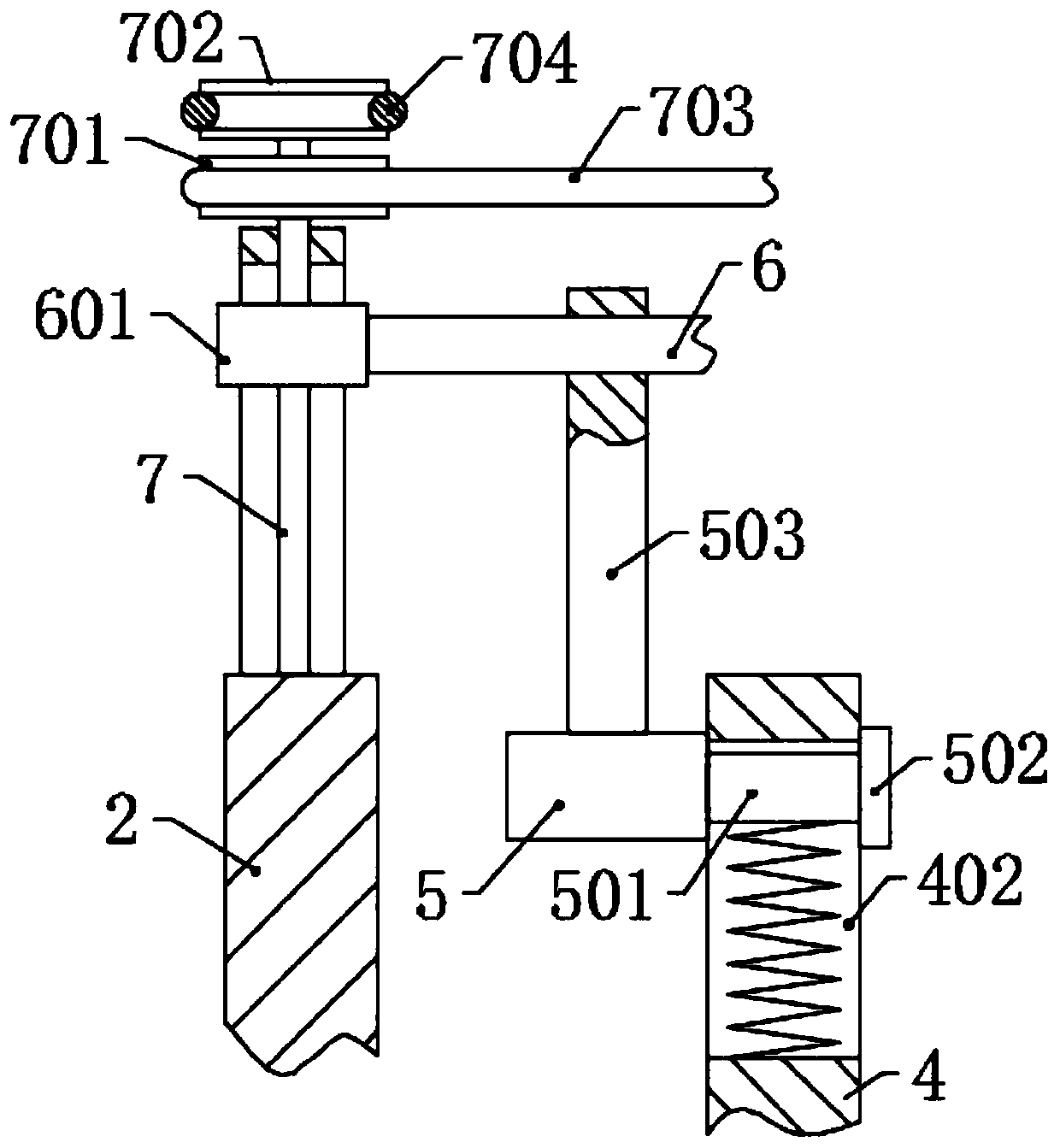

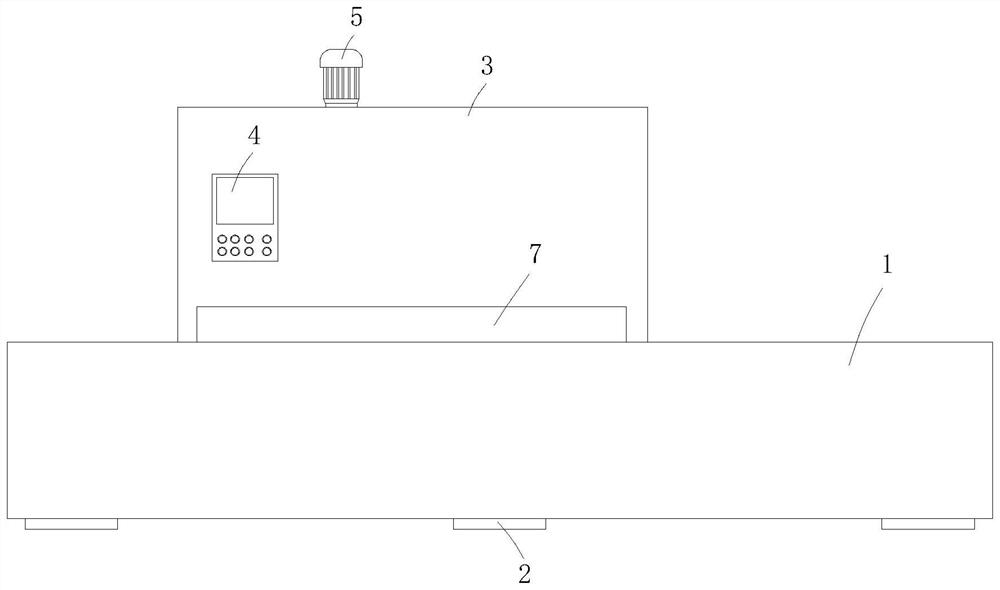

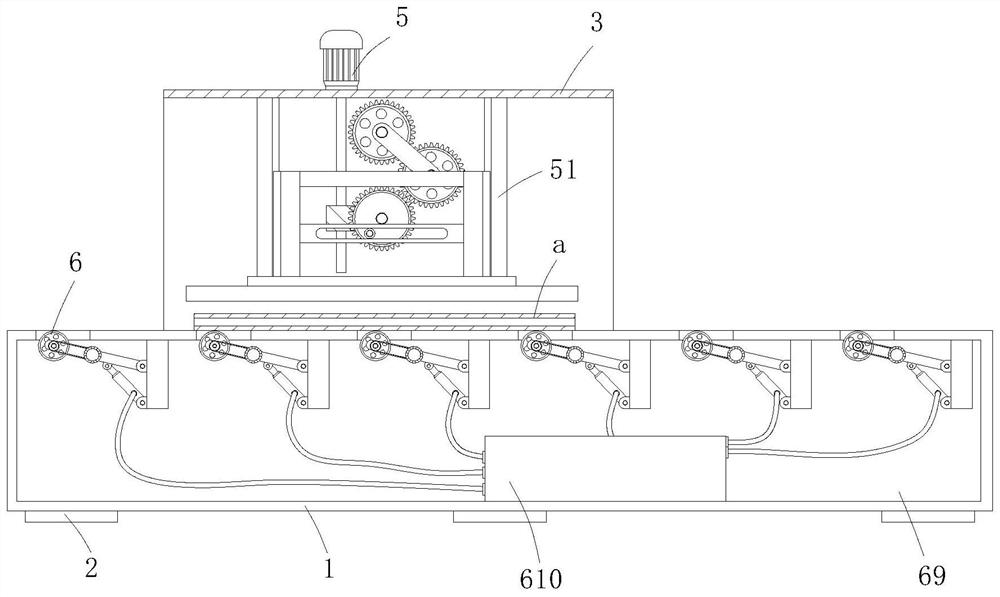

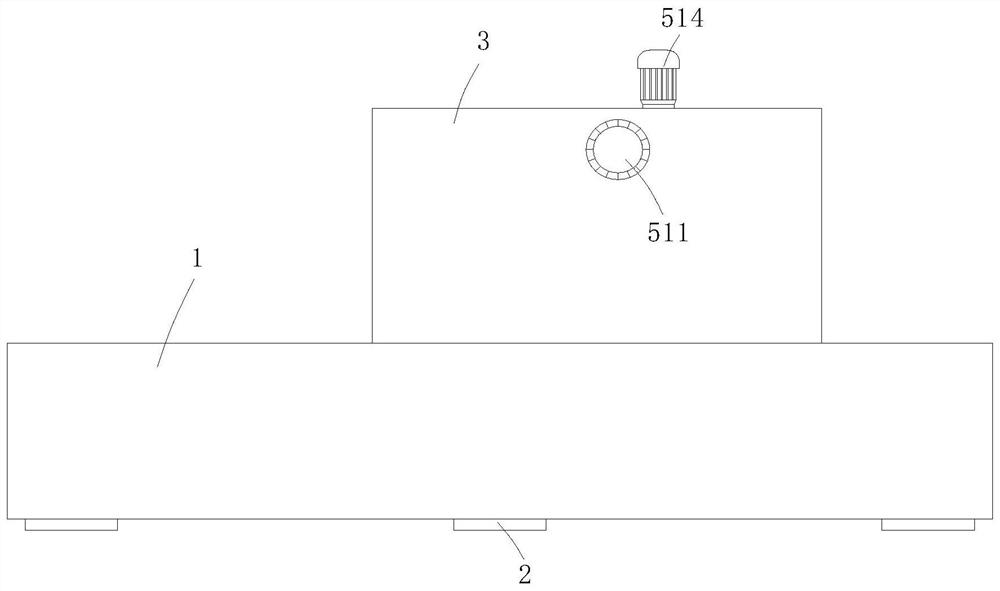

Pad type product production equipment with cutting device

InactiveCN106626688AGood for adequate cooling and settingOverall small sizeLamination ancillary operationsLaminationWork in processMaterial distribution

The invention discloses pad type product production equipment with a cutting device. The pad type product production equipment comprises a machine frame, wherein one end of the machine frame is provided with a conveying belt; a material spreading device is arranged at one end of the conveying belt; a hot press is arranged at the middle part of the conveying belt; the hot press comprises an upper press plate and a lower press plate; the upper press plate and the lower press plate are respectively positioned at the upper side and the lower side of the conveying belt, and are used for performing heating and pressurization on materials on the conveying belt; a material distribution roller is also arranged between the hot press and the material spreading device; a cutting machine and a driving roller are arranged on the machine frame arranged at the other end of the conveying belt; belt-shaped semi-finished products processed and formed through the hot press pass through a position under the cutting machine and then retrace into the cutting machine from the other end of the cutting machine for cutting under the driving of the driving roller. The pad type product production equipment with the cutting device has the advantages that the size is small; the on-line cutting of belt-shaped pad type semi-finished products can be realized.

Owner:浙江熙家科技股份有限公司

Processing technology for improving yarn shrinkage rate of microcapsule fragrant fabric tapes

A disclosed processing technology for improving the yarn shrinkage rate of microcapsule fragrant fabric tapes comprises the following steps: yarn fixing, loosening, dyeing, post-treatment and softening processing. By using a dry blowing machine to perform dry blowing on yarns before dyeing, yarns are fully fixed and the shrinkage rate of the yarns is fully improved; and the dyeing process successively comprises multiple times of water washing at different temperature, so that dyeing is uniform, the color light is pure and the color is uniform; and a microcapsule fragrant finishing agent and an environmental-environment acrylic softening adhesive are added in the dyeing process.

Owner:JIANGSU GOLDEN AUTUMN ELASTIC FABRICS

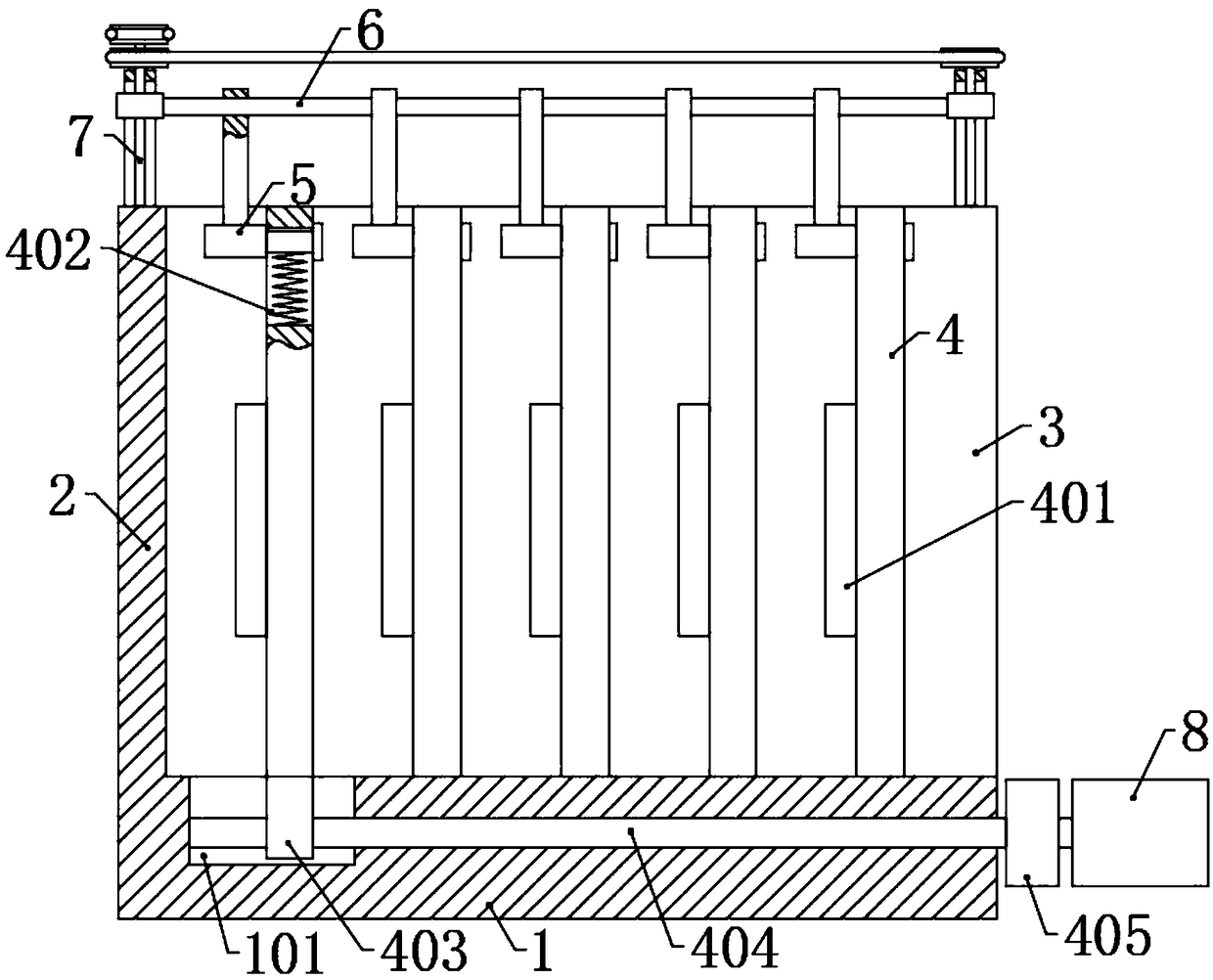

Shaping device for wood door machining

The invention discloses a shaping device for wood door machining in the technical field of wood door machining equipment. The shaping device comprises a base, a first fixing plate, a second fixing plate and movable plates. A plurality of wood doors are placed between the two movable plates, all movable lead screws rotate at the same time through a motor and a gear, the positions of the movable plates are adjusted according to the thickness of the wood doors, accordingly, the wood doors are extruded and shaped through side pressing plates, operation is simple, and shaping is convenient. The screw pitches of the movable lead screws are sequentially increased, and when the movable plates move to any position, the distances between the adjacent movable plates are the same, accordingly, the same-batch multiple wood doors the same in thickness are conveniently shaped at the same time, time and labor are saved, and the shaping efficiency is high. Upper pressing plates move along with the movable plates through movable grooves, sliding blocks and limiting plates, then, a guide rod drives connecting rods and the upper pressing plates to move downwards through lifting lead screws, accordingly, the side edges of the wood doors are shaped, and shaping is comprehensive. The shaping device is simple in operation and convenient to use, wood frames and nails are not needed, materials are saved, and the shaping effect is good.

Owner:安徽忠盛新型装饰材料有限公司

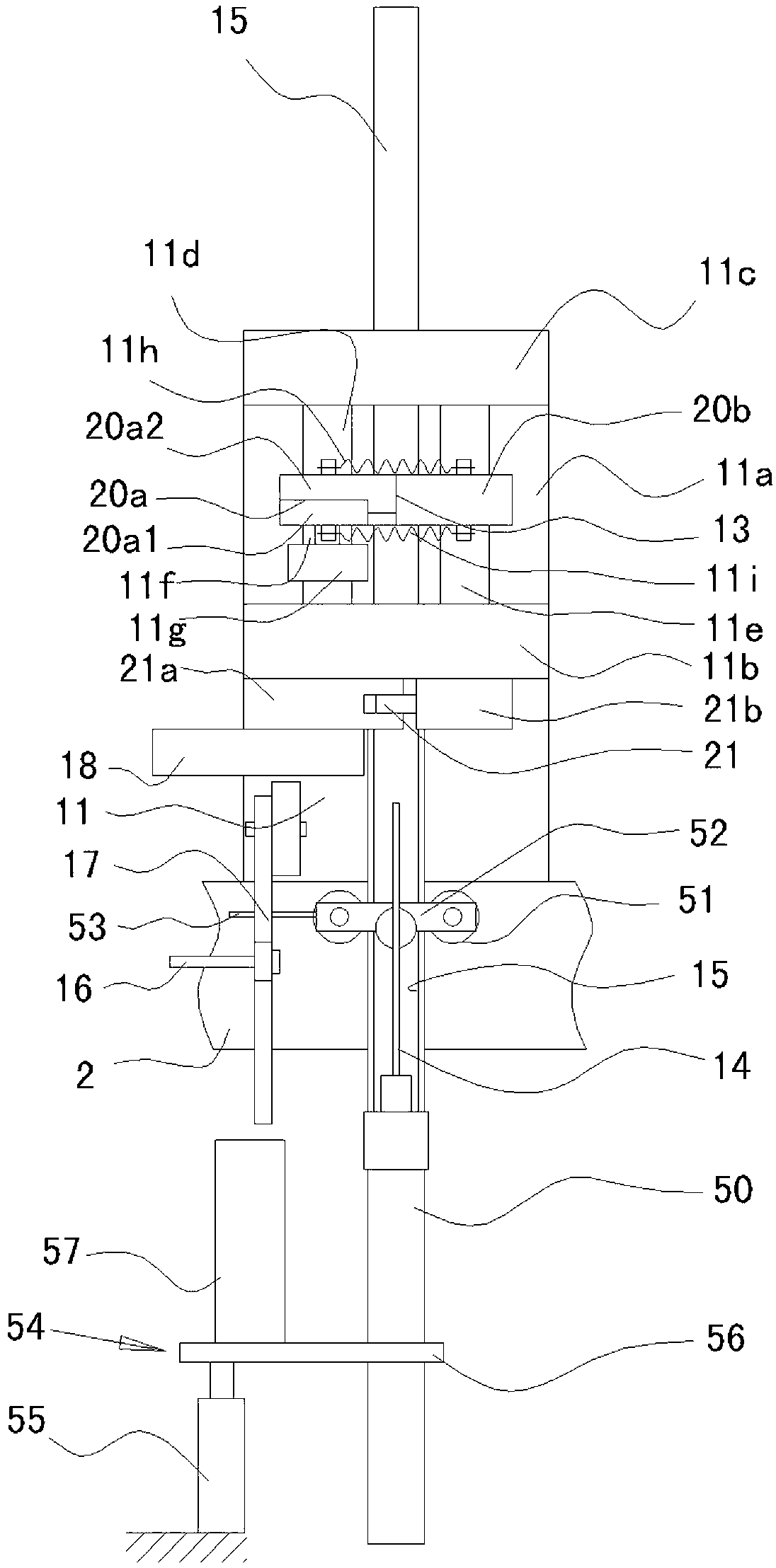

Bending equipment for automobile part profiles

InactiveCN112427508ATo achieve a stereotyped effectStable arc motion trajectoryMetal-working feeding devicesPositioning devicesCrankStructural engineering

The invention discloses bending equipment for automobile part profiles. The equipment comprises an operation table. A power device is arranged at the top of the operation table, and the operation table is provided with a containing part for containing the sheet profiles, a bending executing mechanism and an arc-shaped module which are oppositely distributed on the two sides of the containing part,and a pressing and holding device which is driven by the power device to be arranged from the top of the operation table to the containing part. The pressing and holding device comprises a pressing and holding piece, a rotatable cone frustum arranged at the bottom end of the pressing and holding piece, and a pressing and holding part fixedly arranged at the bottom of the cone frustum and providedwith an inclined bottom face. A crank and rocker mechanism is adopted in the bending executing mechanism, a push rod assembly for pushing and pressing the profiles is arranged on the bending executing mechanism, and the push rod assembly is controlled by the crank and rocker mechanism to do arc-shaped track movement. By means of the bending equipment for the sheet profiles, the physical state andrigidity of the to-be-bent profiles are guaranteed while the bending radian of the sheet profiles is effectively achieved.

Owner:盐城骏拔汽车零部件有限公司

Three-roller superlarge-drafting ironed yarn production method

The invention relates to a three-roller superlarge-drafting ironed yarn production method. A device is arranged at the position of a carriage table top and mainly composed of a baseplate, an electric heating element, a thermolator, a press plate and a shell. The three-roller superlarge-drafting ironed yarn production method can be applied to a three-roller superlarge-drafting spinning machine for simple technical transformation, and the device is mounted on the carriage table top. Fiber roving is output from a front jaw for temperature-adjusting ironing, and yarn is fully shaped, so that hairiness of resultant yarn is reduced, and fibers in the yarn are uniform stressed. Compared with the prior art, the device has the advantages of simplicity and convenience in mounting and high performance-cost ratio.

Owner:JIANGNAN UNIV

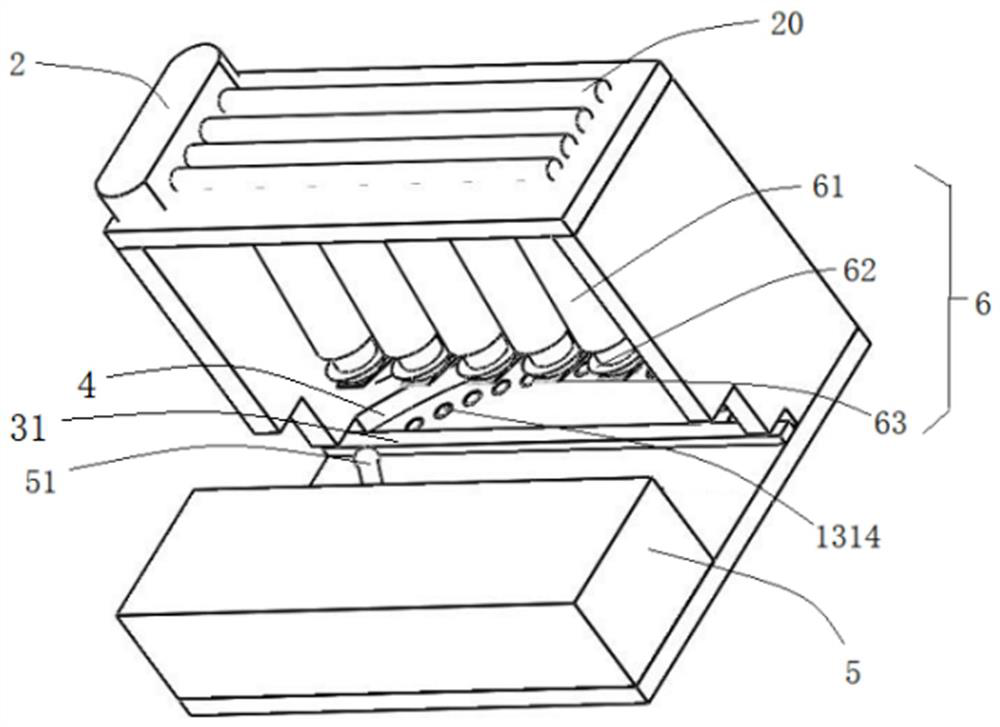

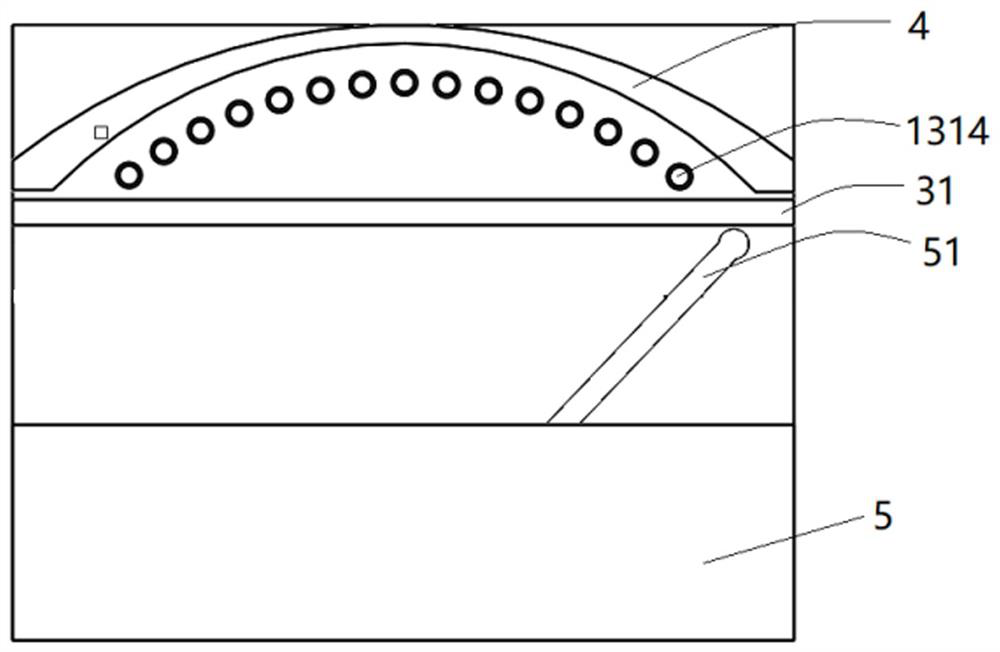

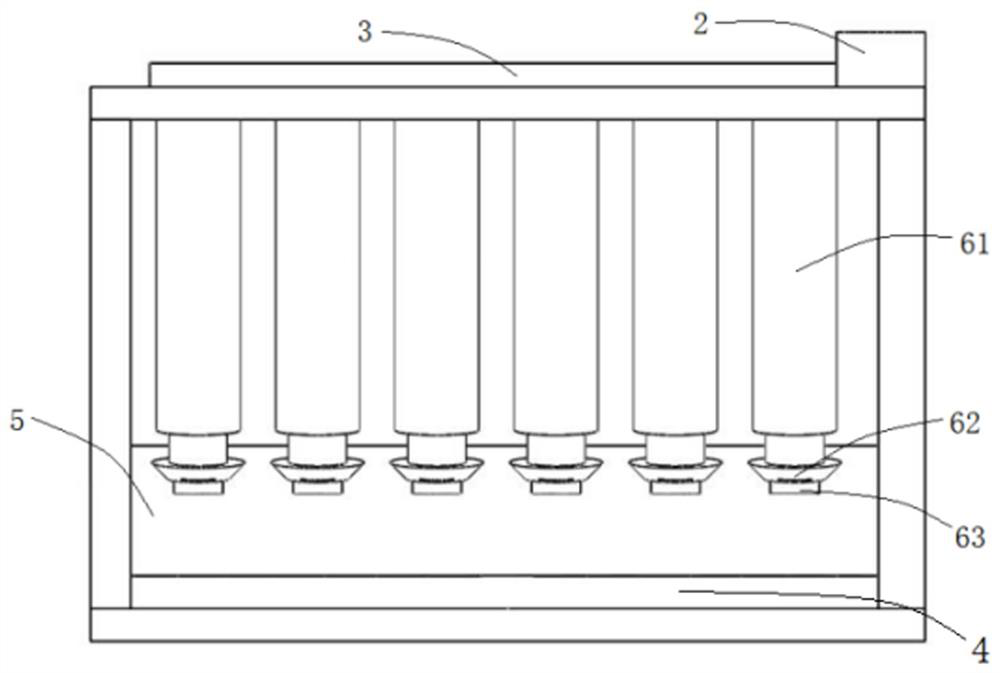

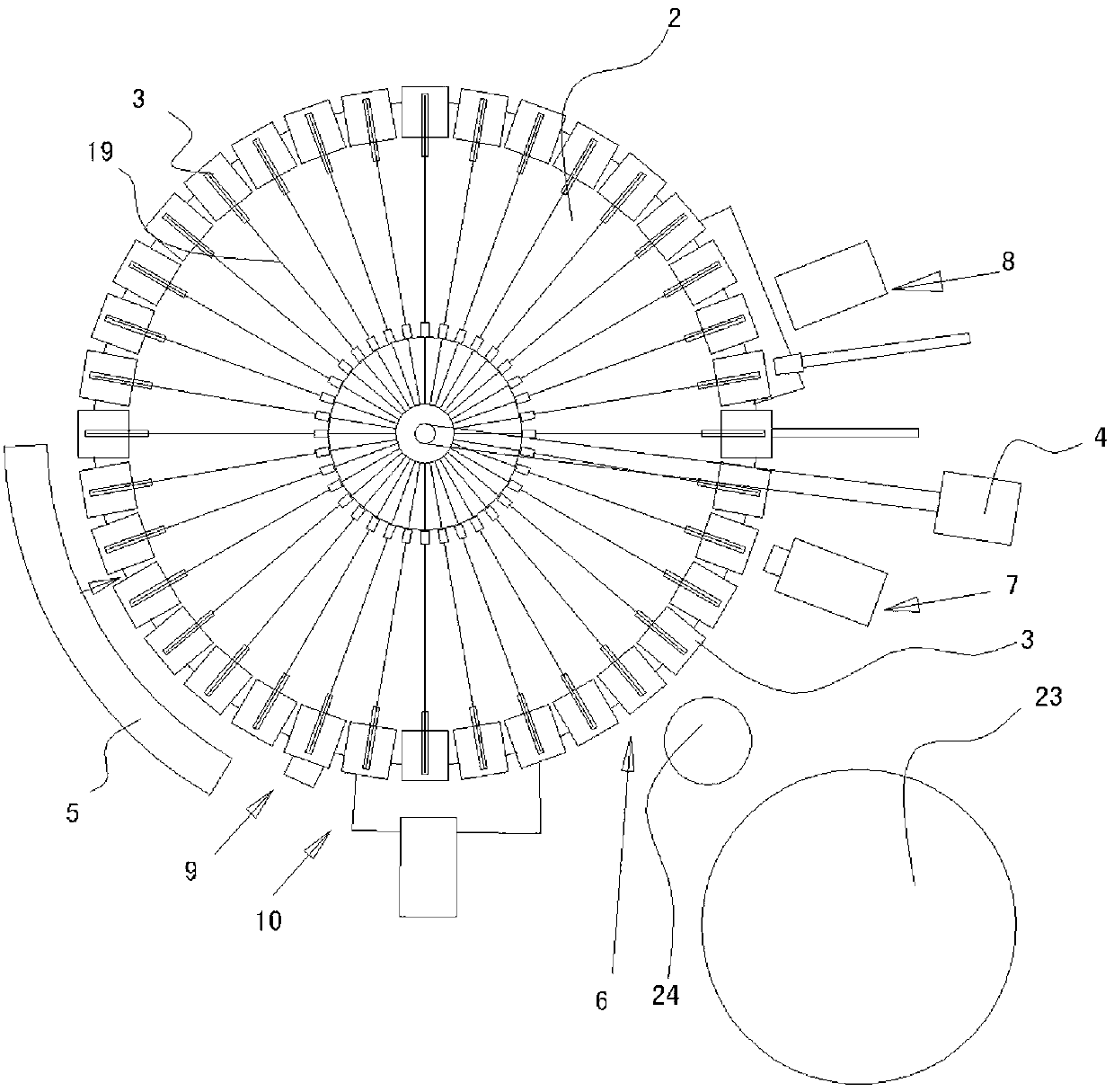

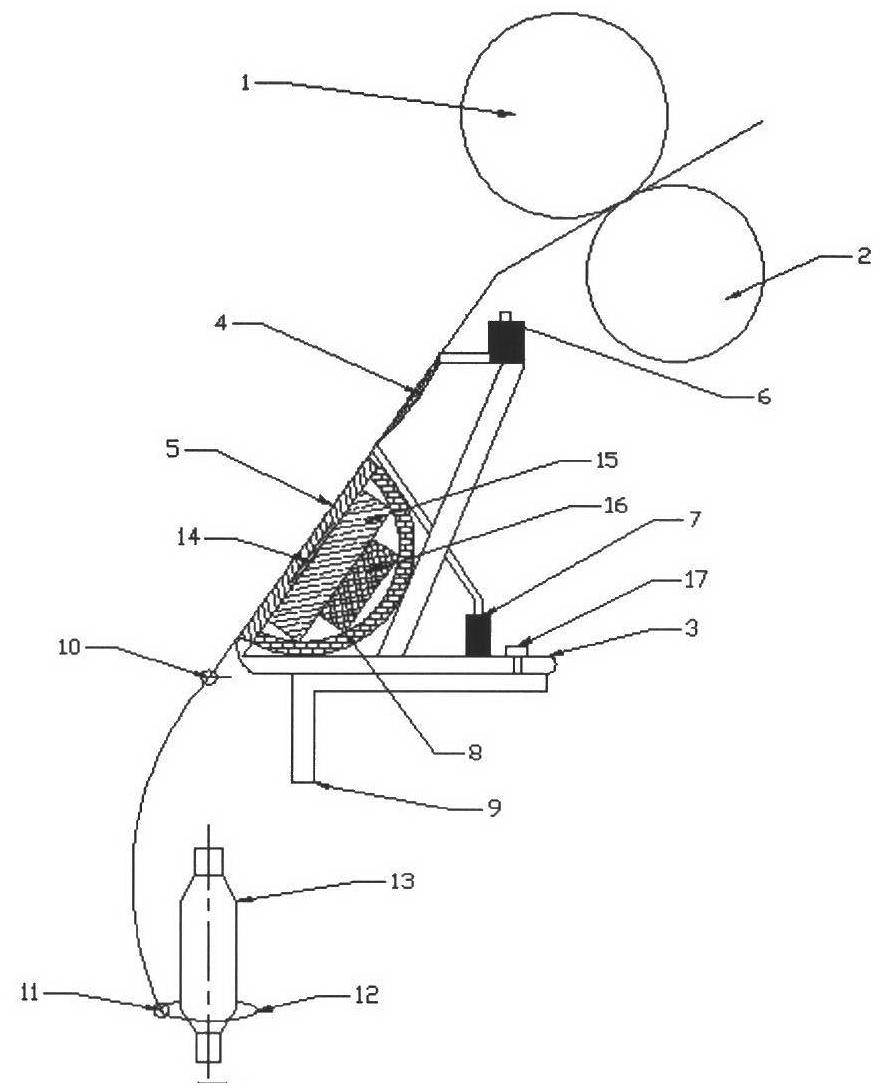

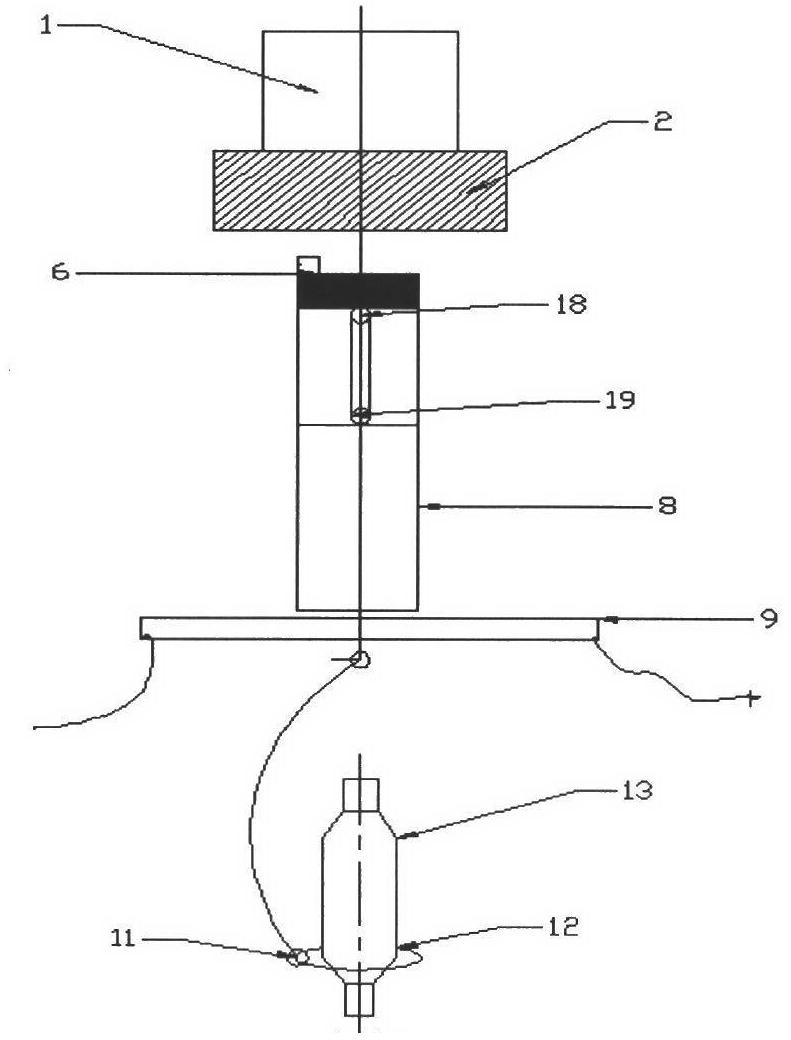

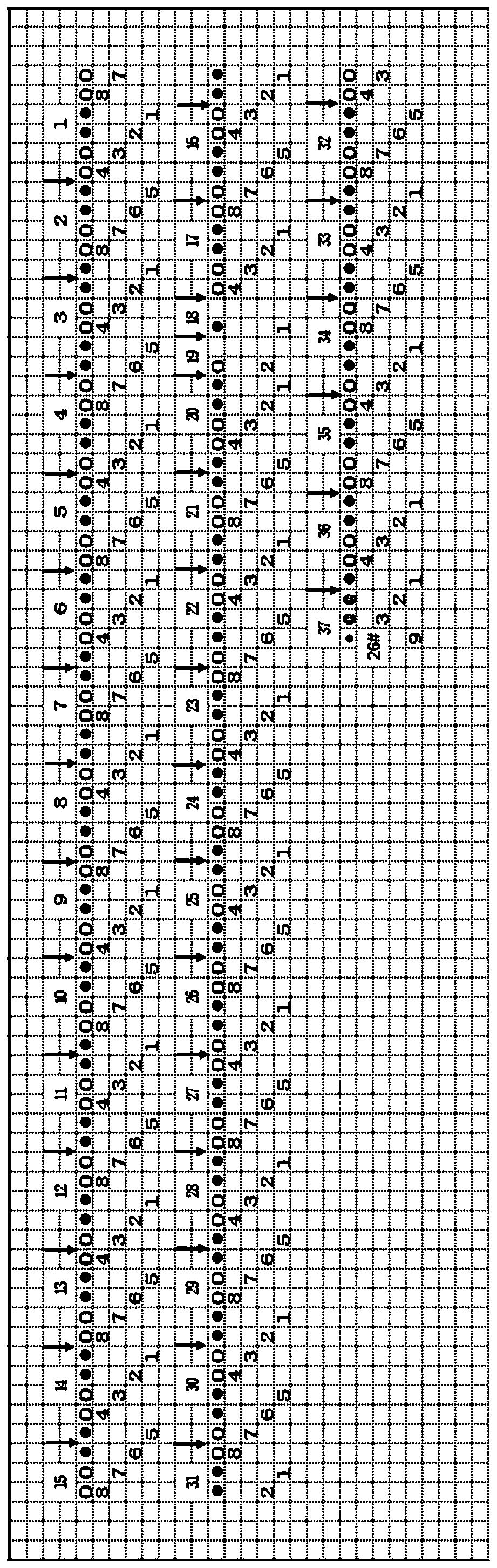

Sizing device for bulb production

InactiveCN103137432AAvoid shaking or even falling offFully stereotypedElectrical apparatusSizingWork in process

A sizing device for bulb production comprises a machine frame, a rotary table, a bulb clamping / blowing device, an air source, a power supply device, an upper bulb station, a station for receiving the blowing device, a sizing station, a station for removing an air inflation device, a station for taking a bulb, a bulb clip and a rod, wherein the upper bulb station, the station for receiving the blowing device, the sizing station, the station for removing the air inflation device, the station for taking the bulb are sequentially arranged along the periphery of the rotary table, the bulb clamping / blowing device comprises a shelf, a high order block is arranged on the rotary table or the shelf, and a handle driving the bulb clip to be opened and closed is arranged on the bulb clip. The sizing device for the bulb production is characterized in that an air blowing mouth is located below a clamping dead of the bulb clip, is a needle-shaped object, and is vertically upward. Compared with the prior art, the sizing device for the bulb production has the advantages that sizing gas is easily inflated into a bulb shell, and semi-finished product bulbs are sufficient in sizing, continuous in delivery, and reliable in fixation.

Owner:李家凌

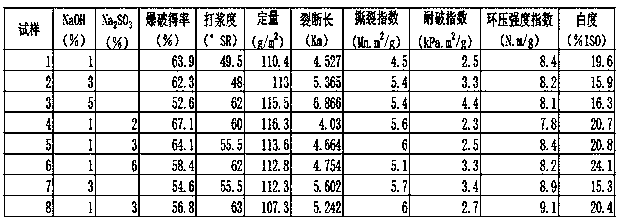

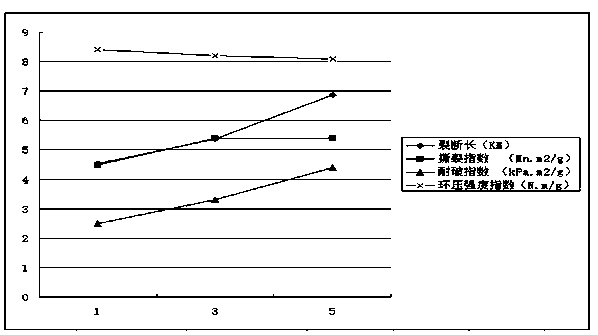

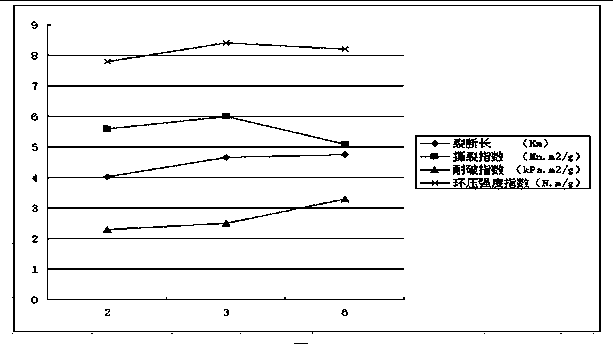

Manufacturing process for high-strength corrugated board

InactiveCN107618210AHigh strengthHigh yieldMechanical working/deformationPulp beating methodsCardboardCrack resistance

The invention relates to a manufacturing process for a high-strength corrugated board. The manufacturing process is improved from an original paper production process to a drying process in a number of aspects, the high strength of the corrugated cardboard is ensured, the crack resistance is high, the rupture resistance and tear resistance are good, and the service life is long. The original paperproduction process is improved, a traditional chemical mechanical method and mechanical method are replaced with an explosion pulping, and obtained original paper has the characteristics of being high in strength, high in yield, low in cost, lower in energy consumption and the like; and a preparation process of a high-strength adhesive is improved, the problem that a starch adhesive is prone to being dilute and unstable in performance in the process of recycling is solved, the situation that the bonding strength and edge crush strength of the corrugated board are decreased due to the fact that the corrugated board produced by using the starch adhesive is prone to getting damp and being soft is avoided, the strength of the corrugated board is improved, preparing and laminating technologiesare improved, the strength of the corrugated board is further improved structurally, a drying technology is improved, and the corrugated board has higher strength and is tightly combined.

Owner:安吉志达包装厂

Thickness setting device of continuous foaming material

ActiveCN111844590ASmall size deviationFully stereotypedFlat articlesWebs handlingPower equipmentIndustrial engineering

The invention belongs to the technical field of production equipment of foaming materials, and particularly discloses a thickness setting device of a continuous foaming material. The thickness settingdevice comprises a foaming cavity and a thickness locking part, wherein the two ends of the foaming cavity are provided with a feeding port and a discharging port respectively, several heating elements are arranged on the inner wall of the foaming cavity in the conveying direction of the foaming material, the thickness locking part is arranged outside the discharging port, and comprises a pressure roll and a steering roll which are oppositely arranged and communicate with a cooling medium pipeline, the surface of at least one of the pressure roll and the steering roll is provided with a cooling structure, at least one of the pressure roll and the steering roll is a driving roll driven by power equipment to rotate, and the foaming material is conveyed out in a way of fitting the surface ofthe steering roll after passing by a pressing area between the pressure roll and the steering roll. By means of the thickness setting device, precise and quick thickness setting of the foaming material can be achieved, dimensional deviation of the finished product is effectively lowered, and the quality of the finished product is improved.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Lubrication ironing spinning device

The invention discloses a paraffin oil and lubrication ironing device which is arranged on a vehicle table top. The device mainly consists of a lubrication system and an ironing system, wherein the lubrication system consists of paraffin oil, a paraffin oil output port, a recycling port, a paraffin oil groove and a recycling bottle; and the ironing system consists of a bottom plate, an electric heating element, a temperature regulator, a pressure plate and a shell. The paraffin oil and lubrication ironing device disclosed by the invention can be applied to a common ring spinning frame to conduct simple technical transformation, and is mounted on the vehicle table top. A fiber strand is output from a front jaw and passes through the paraffin oil groove to stick the hairiness on the yarn surface, thus the cohesive force of the yarn is enhanced, and the yarn is wear-resistant; and then, the yarn is sufficiently formed through the temperature regulation ironing. Compared with the prior art, the device is simple to install and has high cost performance.

Owner:JIANGNAN UNIV

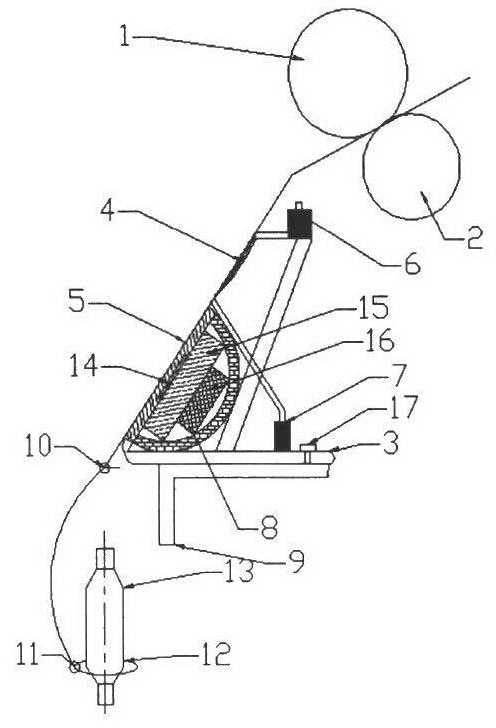

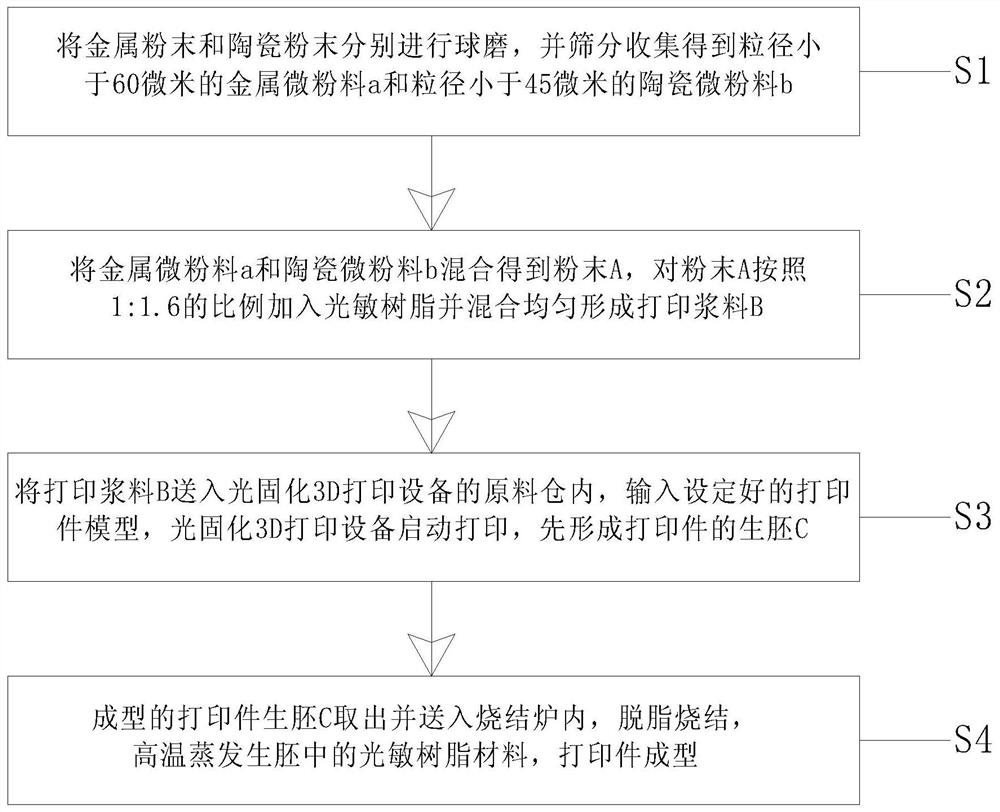

3D printing method of metal ceramic composite material

PendingCN112692300AMeet the needs of useFully stereotypedAdditive manufacturing apparatusTransportation and packagingCeramic compositeMetallic materials

The invention relates to the technical field of 3D printing forming and provides a 3D printing method of a metal ceramic composite material. The 3D printing method of the metal ceramic composite material aims to solve the problem that printing of a metal material and a ceramic material is very difficult to complete through the same 3D printing process due to the characteristics of the material. The 3D printing method of the metal ceramic composite material comprises the following steps of S1, respectively performing ball milling on metal powder and ceramic powder, and screening and collecting to obtain metal micro-powder a with the particle size of less than 60 microns and ceramic micro-powder b with the particle size of less than 45 microns; S2, mixing the metal micro-powder a and the ceramic micro-powder b to obtain powder A, adding photosensitive resin to the powder A according to a ratio of 1: 1.6, and uniformly mixing the photosensitive resin and the powder A to form printing slurry B; and S3, feeding the printing slurry B into a raw material bin of photocuring 3D printing equipment, inputting a set printed piece model, enabling the photocuring 3D printing equipment to start printing, and firstly forming a green body C of a printed piece. The 3D printing method of the metal ceramic composite material is particularly suitable for 3D printing of the metal ceramic composite material, and possesses higher social use value and application prospect.

Owner:德亿纬三维打印科技(太仓)有限公司

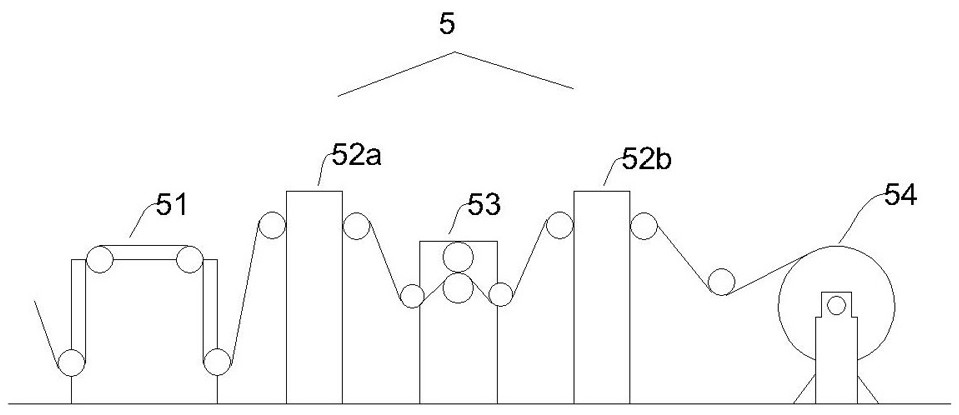

Preparation method of high-bulkiness high-strength DTY (Draw Textured Yarn)

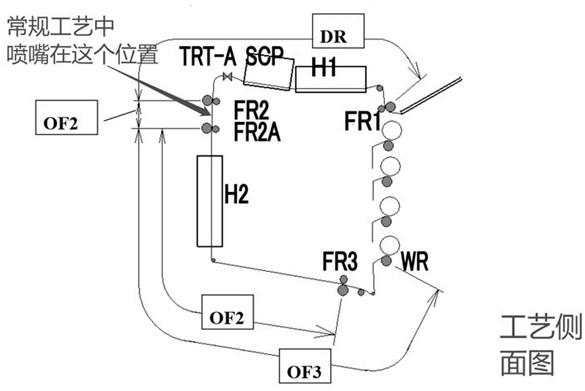

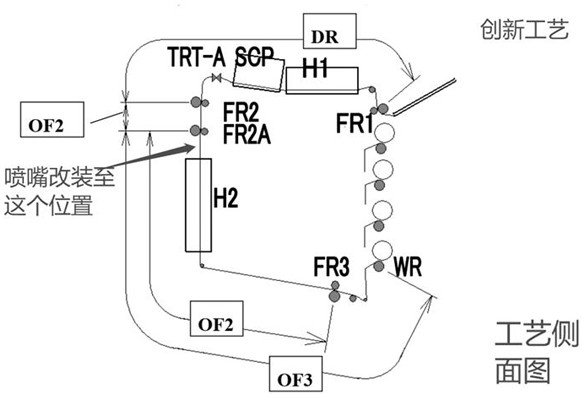

The invention discloses a preparation method of high-bulkiness and high-strength DTY (Draw Textured Yarn), which is characterized in that after a network nozzle is transformed to an FR2A shaft, the speed of the FR2A shaft is greater than that of the FR2 shaft, that is, false-twisted DTY tows are pulled open (cold-drawn) through a speed difference, and after the pulled-open DTY tows are loosened, single fibers are not mutually twisted, so that the high bulkiness of the yarns is kept. And then heat setting is carried out in a second hot box H2, so that the fluffiness stability of the DTY tows is improved. And different network styles of the yarns can be realized by adjusting the speed difference between the FR2A shaft and the FR3 shaft. And the DTY with high strength and high bulkiness is produced.

Owner:CHANGLE HENGSHEN SYNTHETIC FIBER

Fruity milk steamed cake and making method thereof

InactiveCN105639432AReach equilibriumMeet the needs of different groups of peopleFood scienceVegetable oilFruit juice

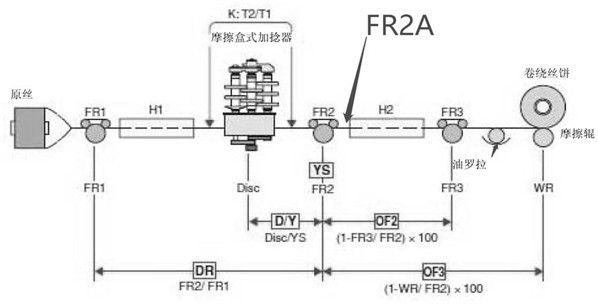

The invention discloses a fruity milk steamed cake and a making method thereof and belongs to the technical field of food processing. The fruity milk steamed cake is made of, by weight, 45-55 parts of wheat flour, 40-50 parts of white granulated sugar, 55-60 parts of egg, 8-12 parts of edible plant oil, 1-3 parts of edible glucose, 5-8 parts of glucose syrup, 0.8-1.2 parts of milk powder, 0.8-1.2 parts of edible salt, 2-5 parts of cake oil, 0.08-0.12 part of baking powder, 0.05-0.08 part of potassium sorbate, 0.05-0.08 part of sodium dehydroacetate, 0.08-0.12 part of edible citric acid, 0.08-0.15 part of concentrated fruit juice. The concentrated fruit juice is added to generate fruity smell, and edible essence is not added, so that hygiene and safety of the steamed cake are guaranteed. The preparation method includes: selecting and weighing raw materials, mixing and stirring, pulping, injecting pulp, steaming, demolding and cooling, picking and packing. An improved steaming process is adopted, so that the fruity milk steamed cake is safe, hygienic and free of damage to nutritional ingredients, and original flavor of food is retained. The steamed cake made by the method is smooth in mouthfeel, mellow in texture, strong in fruity smell, rich in nutrition and popular with people at all ages.

Owner:FUJIAN SENYOU FOOD CO LTD

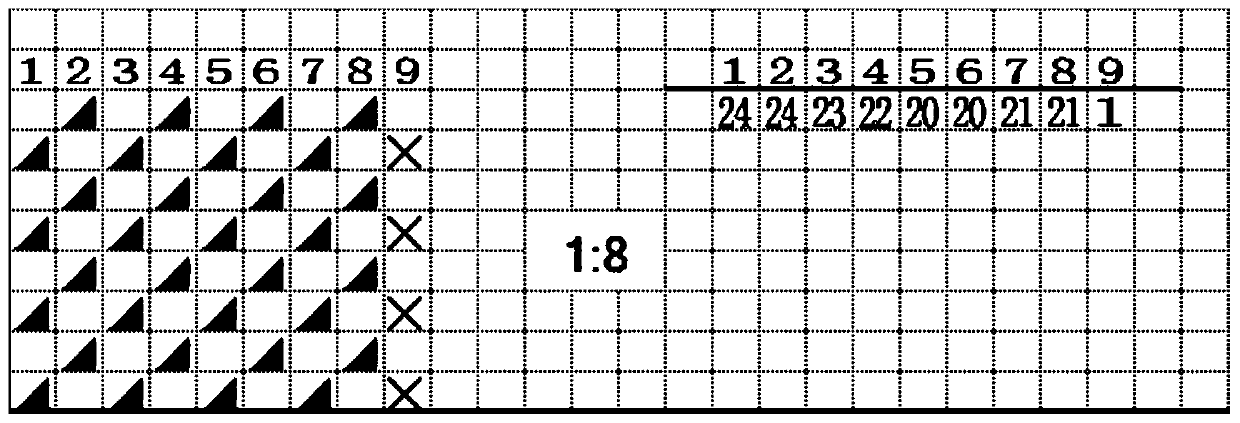

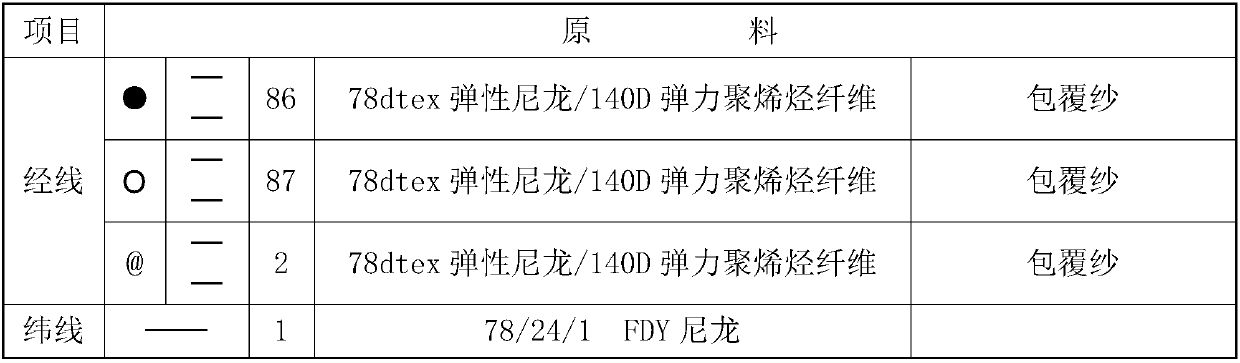

A processing technology for improving the shrinkage rate of high resilience shoulder strap yarn

ActiveCN104032502BFully stereotypedImprove shrinkageBrassieresLiquid/gas/vapor yarns/filaments treatmentYarnPulp and paper industry

The invention discloses a processing technic for improving yarn shrinkage of a high-resilience shoulder strap. The processing technic for improving the yarn shrinkage of the high-resilience shoulder strap comprises the following steps of yarn setting, scarifying, dyeing, postprocessing and excessive soft processing. According to the processing technic for improving the yarn shrinkage of the high-resilience shoulder strap, dry blowing is carried out on yarn through a dry blowing machine before dyeing is carried out, the yarn is set fully firstly, and the shrinkage of the yarn can be improved fully; in the dyeing process, water washing under different temperatures are carried out several times in sequence, dyeing is made to be even, colored light is pure, and the color is even.

Owner:JIANGSU GOLDEN AUTUMN ELASTIC FABRICS

Production process of IPET thickened container

The invention discloses a production process of an IPET thickened container, and belongs to the technical field of plastic containers. The process comprises the following steps: (1) IPET particles are fully dried; (2) after the dried IPET particles enter an injection molding machine through a drying hopper, through a screw mixer of the injection molding machine, the dried IPET particles are fully mixed and molten at the temperature of 220 DEG C and put into a mold, and a bottle blank is obtained; and (3) the bottle blank is put into a bottle blowing machine to position a blank head, exhausting is performed after first-time blowing forming, and then second-time circulating blowing forming is performed to ensure that the product is not shrunk after being cooled, so as to obtain a finished product with the thickness of 8 mm or more. A screw is used for mixing before injection molding, a mixer is integrated at the head part of the screw, and the molten IPET is fully mixed when passing through the head part of the screw, so that the raw materials are molten more uniformly. Compared with single-time blowing, secondary circulating blowing is utilized, so that an IPET thick-wall bottle can be fully shaped, the wall thickness of a bottle body is kept uniform, the bottle body stands stably, and the bottle body has good gloss.

Owner:上海川禾包装容器有限公司

A processing technology for improving the yarn shrinkage of microcapsule aromatic webbing

The invention discloses a processing technology for improving the shrinkage rate of the yarn of the microcapsule aromatic webbing, which comprises the following steps: yarn setting, loosening, dyeing, post-treatment, and over-softening treatment. In the present invention, the yarn is dry-steamed with a dry steamer before dyeing, so that the yarn is fully shaped first, and the shrinkage of the yarn can be fully improved; the dyeing process part is successively washed with water at different temperatures several times, so that The dyeing is uniform, the shade is pure, and the color is uniform, and the microcapsule aromatic finishing agent and the environmentally friendly acrylic soft adhesive are added in the dyeing process.

Owner:JIANGSU GOLDEN AUTUMN ELASTIC FABRICS

A kind of optical reflective film with low heat shrinkage and its preparation method

ActiveCN106125173BInternal stress release completelyGood dimensional stabilityMirrorsSynthetic resin layered productsPolyesterOptical reflection

The invention relates to the field of polyester films, and specifically relates to an optical reflection film with a low thermal shrinkage rate, and a preparation method therefor. The reflection film comprises a reflection film main layer and an auxiliary layer on the main layer. The main layer comprises thermoplastic resin, incompatible resin, white inorganic filling particles and a nucleating agent. The auxiliary layer comprises thermoplastic polyester, an anti-adhesion agent and an antistatic agent. The reflection film is better in size stability, is excellent in flatness when being used in a backlight module group, and cannot be wrinkled because of temperature changes.

Owner:苏州盛达飞智能科技股份有限公司

Mat production equipment with cutting device

InactiveCN106626688BSolve the lack of cooling capacityFully stereotypedLamination ancillary operationsLaminationWork in processMaterial distribution

The invention discloses pad type product production equipment with a cutting device. The pad type product production equipment comprises a machine frame, wherein one end of the machine frame is provided with a conveying belt; a material spreading device is arranged at one end of the conveying belt; a hot press is arranged at the middle part of the conveying belt; the hot press comprises an upper press plate and a lower press plate; the upper press plate and the lower press plate are respectively positioned at the upper side and the lower side of the conveying belt, and are used for performing heating and pressurization on materials on the conveying belt; a material distribution roller is also arranged between the hot press and the material spreading device; a cutting machine and a driving roller are arranged on the machine frame arranged at the other end of the conveying belt; belt-shaped semi-finished products processed and formed through the hot press pass through a position under the cutting machine and then retrace into the cutting machine from the other end of the cutting machine for cutting under the driving of the driving roller. The pad type product production equipment with the cutting device has the advantages that the size is small; the on-line cutting of belt-shaped pad type semi-finished products can be realized.

Owner:浙江熙家科技股份有限公司

Nylon pipe shaping device

The invention relates to the technical field of nylon pipes, and discloses a nylon pipe shaping device. The nylon pipe shaping device comprises a lower die plate and an upper die plate, wherein circular grooves are formed in the side walls of the sides, opposite to each other, of the upper die plate and the lower die plate; a fixing plate is fixedly connected to the lower end of the lower die plate, and a rotating plate is fixedly connected to the lower end of the upper die plate; a fixing shaft is fixedly connected to the side wall of the front side of the fixing plate, a shaft hole is formedin the side wall of the front side of the rotating plate, and the fixing shaft penetrates through the rotating plate through the shaft hole; a mounting plate is fixedly connected to the upper end ofthe lower die plate, and a U-shaped groove is formed in the side wall of the upper side of the mounting plate; and a rotating shaft is fixedly connected between the groove walls of the opposite sidesof the U-shaped groove, and the rotating shaft is movably provided with an L-shaped buckle plate in a sleeved mode. The nylon pipe shaping device can comprehensively shape the nylon pipes, and the shaping effect is effectively improved.

Owner:十堰铁马汽车零部件有限公司

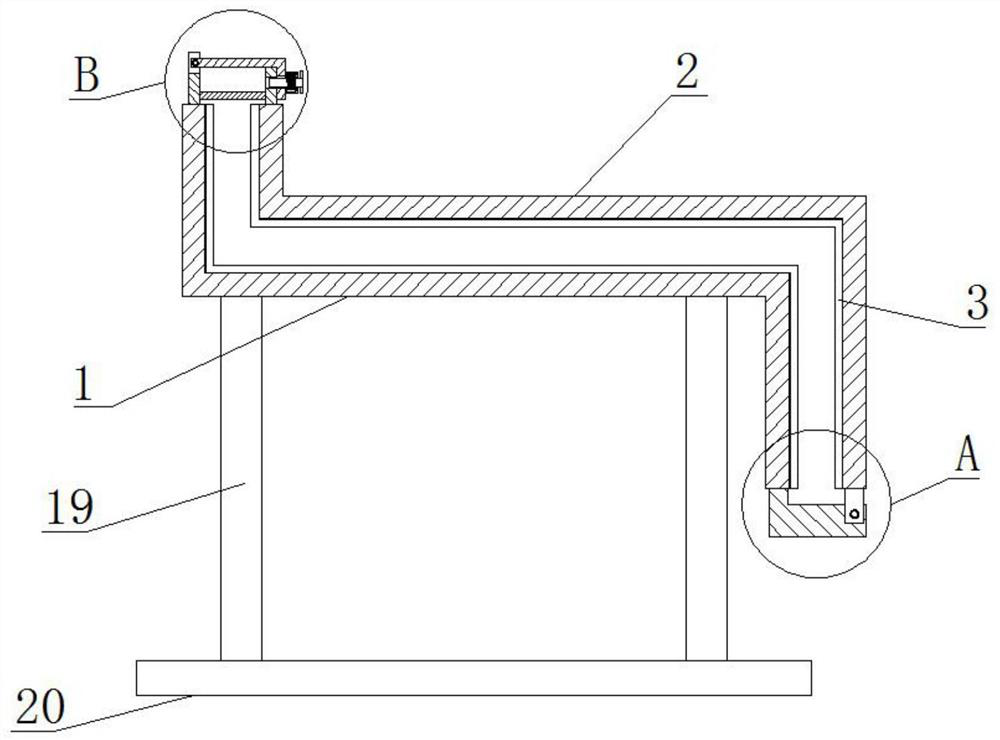

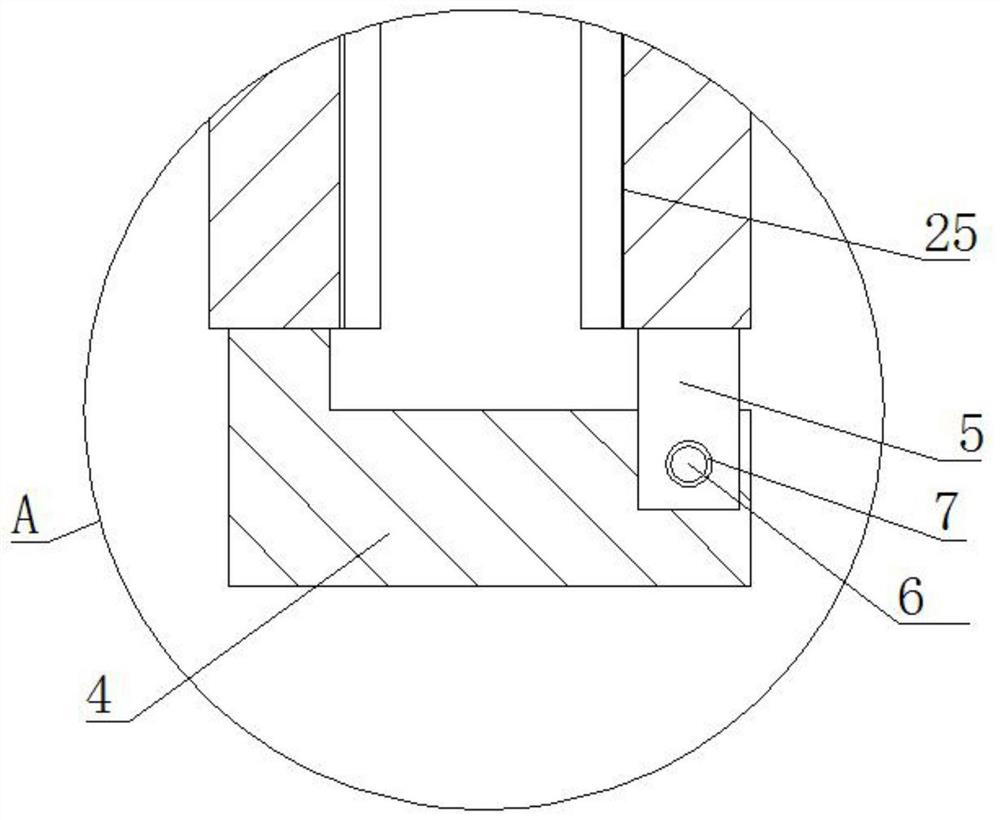

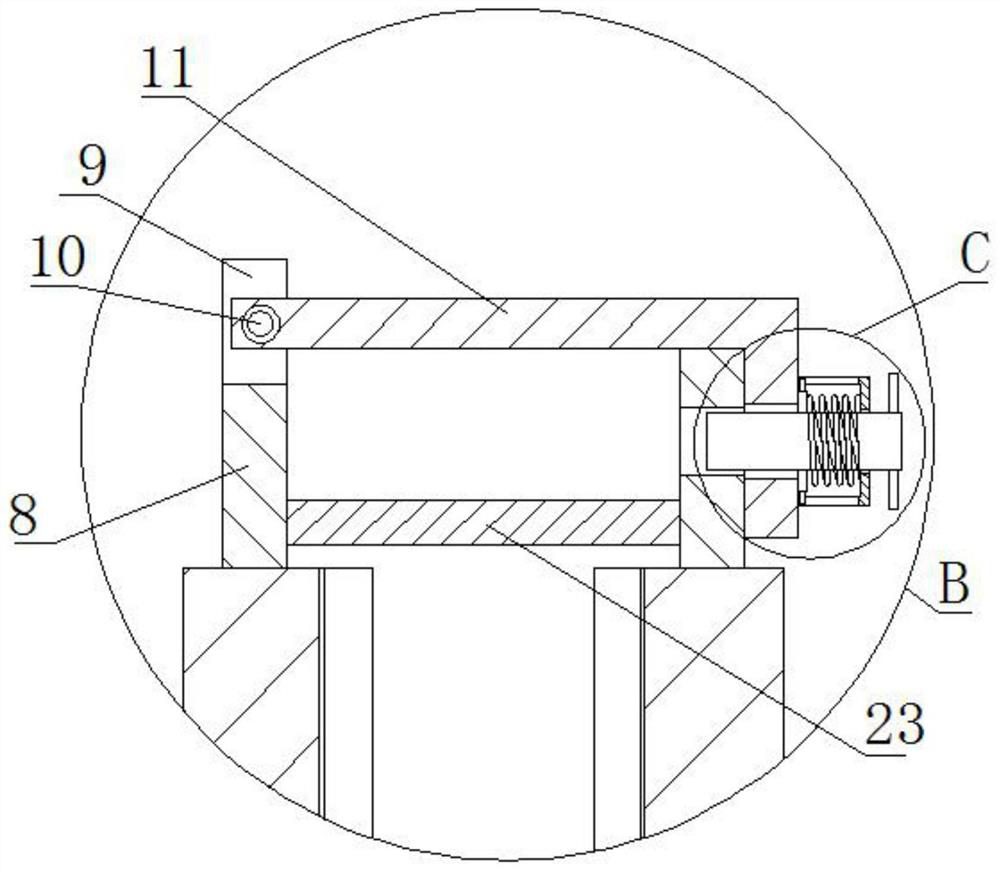

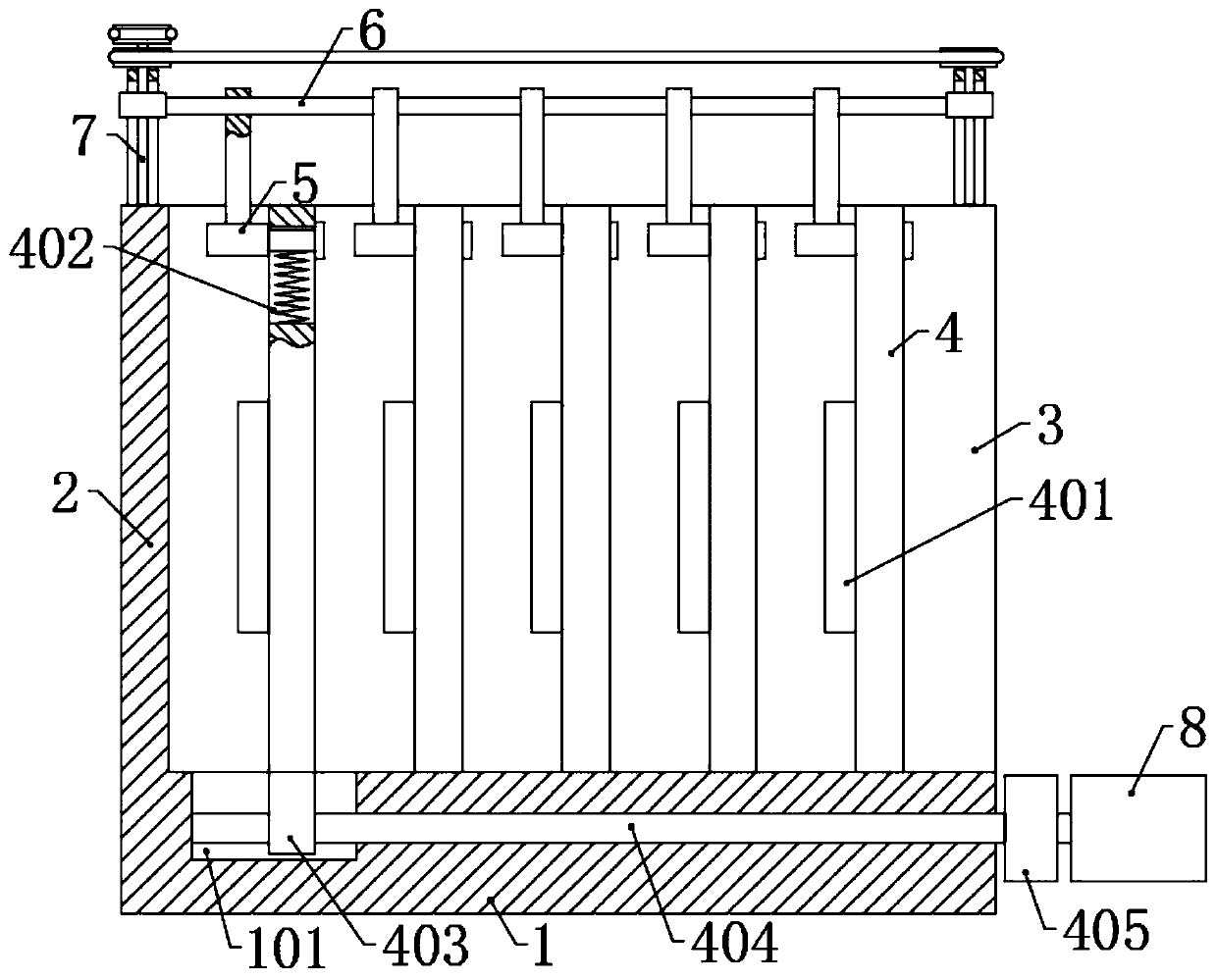

A shaping device for wooden door processing

The invention discloses a shaping device for wood door machining in the technical field of wood door machining equipment. The shaping device comprises a base, a first fixing plate, a second fixing plate and movable plates. A plurality of wood doors are placed between the two movable plates, all movable lead screws rotate at the same time through a motor and a gear, the positions of the movable plates are adjusted according to the thickness of the wood doors, accordingly, the wood doors are extruded and shaped through side pressing plates, operation is simple, and shaping is convenient. The screw pitches of the movable lead screws are sequentially increased, and when the movable plates move to any position, the distances between the adjacent movable plates are the same, accordingly, the same-batch multiple wood doors the same in thickness are conveniently shaped at the same time, time and labor are saved, and the shaping efficiency is high. Upper pressing plates move along with the movable plates through movable grooves, sliding blocks and limiting plates, then, a guide rod drives connecting rods and the upper pressing plates to move downwards through lifting lead screws, accordingly, the side edges of the wood doors are shaped, and shaping is comprehensive. The shaping device is simple in operation and convenient to use, wood frames and nails are not needed, materials are saved, and the shaping effect is good.

Owner:安徽忠盛新型装饰材料有限公司

Shaping device for production of stone insulation integrated board

ActiveCN112026223AFully stereotypedRealize position adjustmentPress ramMechanical engineeringIndustrial engineering

The invention relates to the technical field of machining equipment of stone insulation boards, provides a shaping device for production of stone insulation integrated boards, and aims at solving problems that when a conventional shaping device is used for machining, on one hand, the shaping efficiency and the shaping precision are low, and board surface damage is likely to occur; on the other hand, the lifting stroke of the shaping pressing plate face is fixed in a matched manner, and the shaping pressing plate face fails to meet the production requirements of insulation stone integrated boards with different thicknesses. The shaping device comprises a strip-shaped base box and a plurality of supporting foot pads arranged at the lower end of the strip-shaped base box, a stone board shaping chamber is arranged at the upper end of the strip-shaped base box, a stone board shaping mechanism is arranged in the stone board shaping chamber, the stone board shaping mechanism comprises a rectangular frame vertically arranged in an inner cavity of the stone board shaping chamber, and a shaping pressing plate is arranged at the lower end of the rectangular frame. The device is particularly applicable to pressing and shaping of the stone insulation integrated boards, and has high social usage value and application prospect.

Owner:安徽镜铭建筑装饰工程有限公司

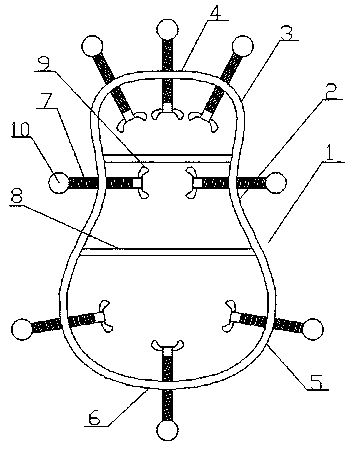

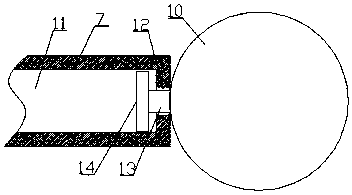

Multi-point acoustic guitar side plate shape-forming support device

The invention discloses a cross-shaped acoustic guitar side plate shape-forming bracket, which comprises two parallel adjusting flat plates. Each of two ends of the adjusting flat plates are connectedwith an adjusting rod via a rotating shaft; the top ends of the adjusting rods on the same side are connected with supporting plates through rotating shafts; horizontal supporting rods are connectedto one sides of the supporting plates; an adjusting screw rod is arranged between the adjusting flat plates; one end of the adjusting screw rod is movably connected to one adjusting flat plate, and the other end of the adjusting screw rod passes through the other adjusting flat plate and is threadingly connected to the adjusting flat plate; longitudinal threaded sleeves are arranged on opposite outer sides of the adjusting flat plates; longitudinal supporting rods are connected in the longitudinal threaded sleeves; and the longitudinal supporting rods have outer threaded sections matching thelongitudinal threaded sleeves. The invention is easy to use, is good in shape-forming effect, is wide in application range, and is easy to store.

Owner:贵州贝加尔乐器有限公司

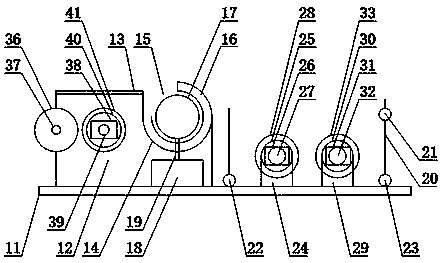

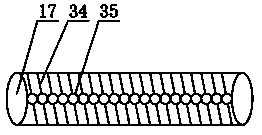

A processing technology of elastic edging belt

ActiveCN107700016BImprove shrinkageFully stereotypedTextile treatment containersHeating/cooling textile fabricsFiberPolymer science

The invention discloses a processing technology of an elastic edging belt, which comprises: a material preparation step: selecting elastic polyolefin fibers; and then going through a relaxation and retraction step, a presetting step, a covering yarn step, a weaving step, a fabric setting step, and a fabric dyeing step. After the finishing step, the post-processing step and the drying step, the elastic edging tape is obtained. The elastic edging belt produced by the processing technology of the present invention has the characteristics of high resilience and low shrinkage rate.

Owner:中山敦明纺织有限公司

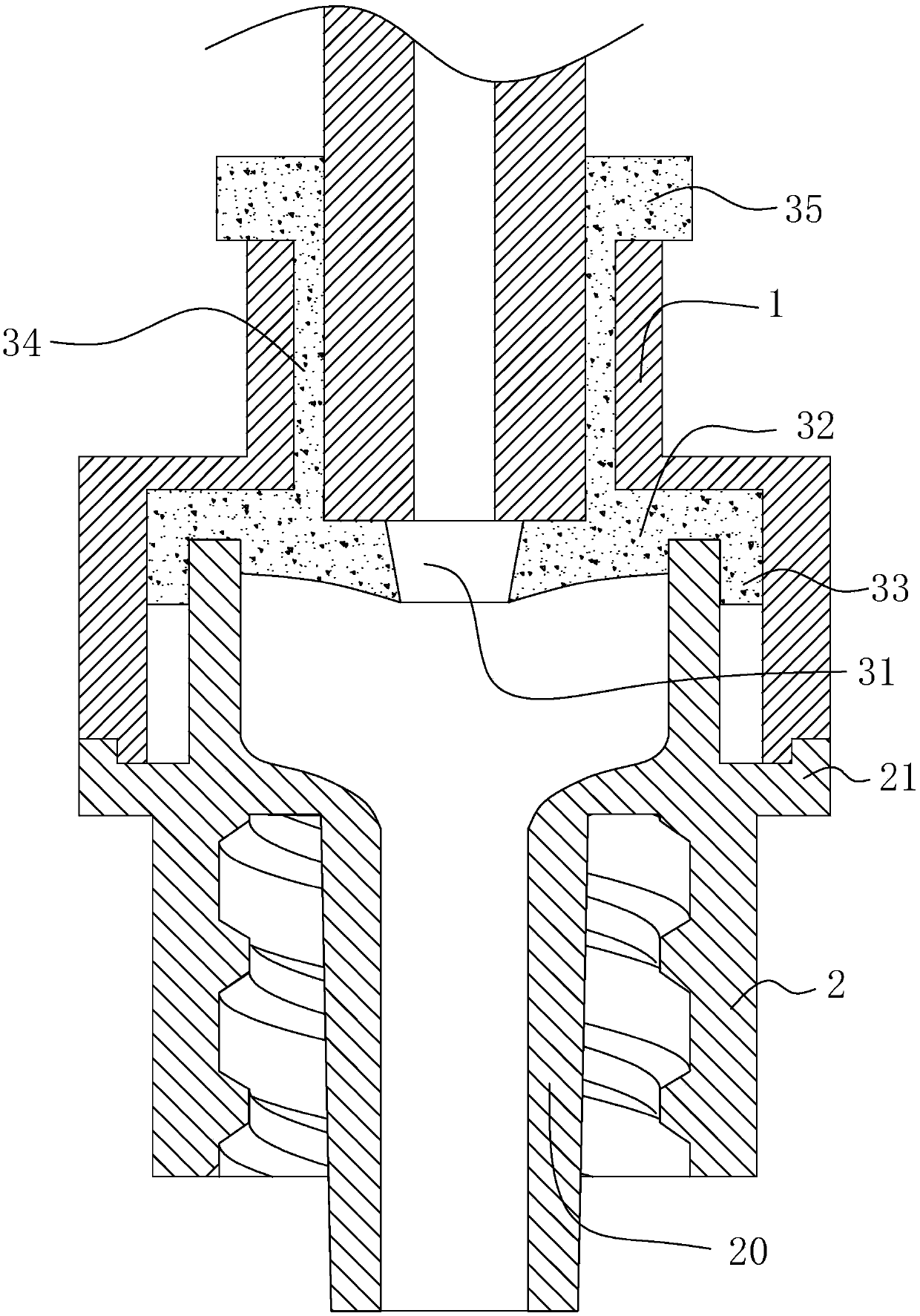

Rubber valve and anti-self-adhesion medical infusion connector

The invention discloses a rubber valve. A manufacturing process comprises the following steps: step 1) carrying out first-time vulcanization to form a colloid valve body, wherein the material of the colloid valve body is rubber or silica gel; step 2) cutting the colloid valve body to form a liquid through hole which is sealed at a normal state; step 3) smearing the liquid through hole with volatile liquid; step 4) carrying out second-time vulcanization on the colloid valve body smeared with the volatile liquid. According to the rubber valve disclosed by the invention, the volatile liquid is smeared on the cut and the second-time vulcanization is carried out so that a cut surface can be sufficiently cured and shaped, so that a condition that the cut is adhered after long-time contact can beprevented from occurring. The manufacturing process is used for the rubber valve and an infusion connector is used for medical equipment.

Owner:GUANGDONG BAIHE MEDICAL TECH CO LTD

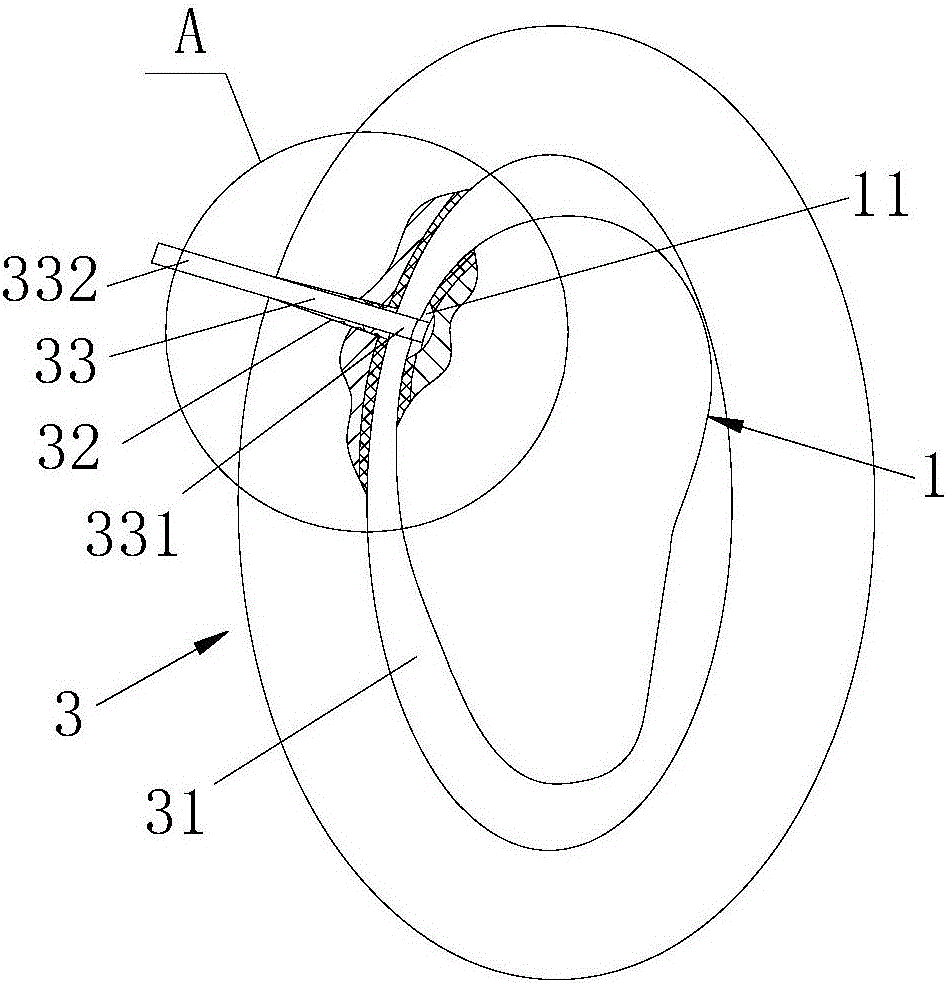

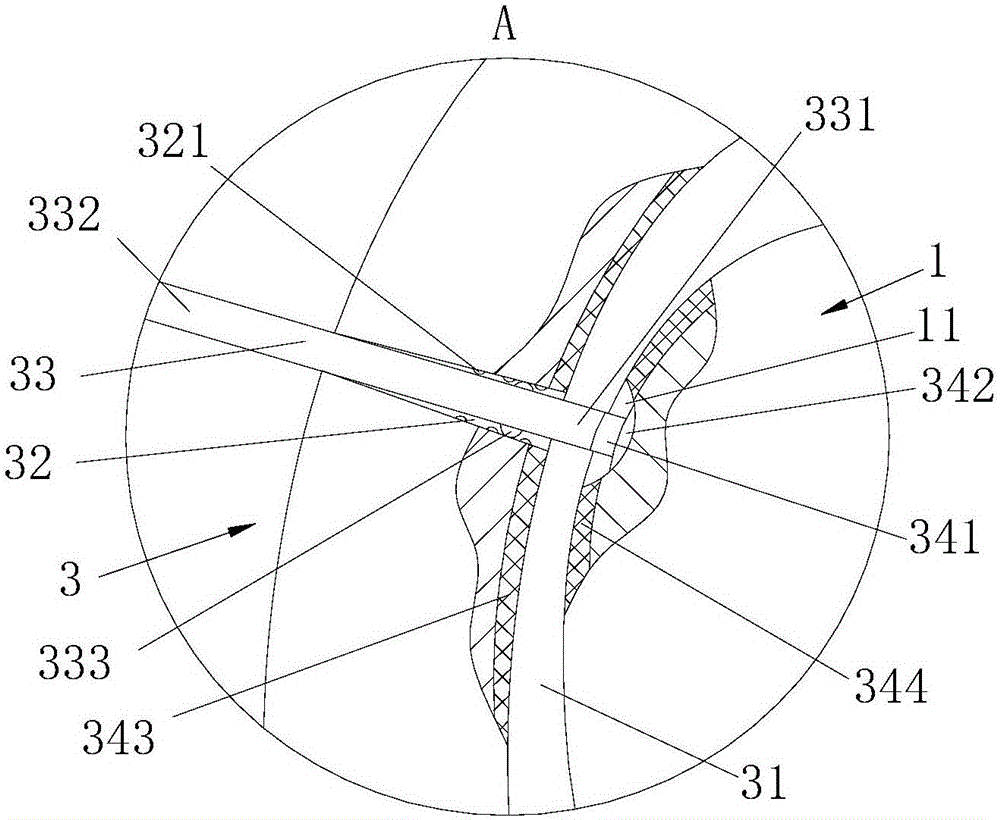

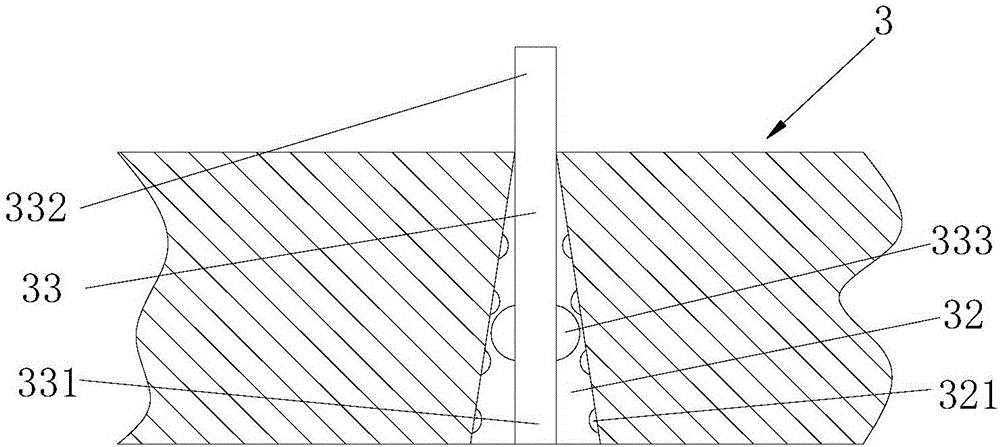

Auricular point stimulator

PendingCN106362295AStimulation is accurateImprove fitElectrotherapyDevices for locating reflex pointsAudiology

The present invention discloses an auricular point stimulator. The auricular point stimulator comprises an ear sleeve shaped to match the shape of the auricle of a user and a plurality of ear stimulation units mounted on the ear sleeve; an auricle cavity for accommodating the auricle is formed in the ear sleeve; the auricular point stimulator further comprises a shaping sleeve, a plurality of shaping channels, shaping rods and positioning blocks; the shaping sleeve covers the ear sleeve; a shaping cavity for accommodating the ear sleeve is formed in the shaping sleeve; the plurality of shaping channels are formed in the shaping sleeve; the shaping rods are inserted into the shaping channels and are in sliding matching with the shaping channels; end portions of the shaping rods, which are adjacent to the shaping cavity, are positioning ends; end portions of the shaping rods, which are far from the shaping cavity, are control ends; the positioning blocks protrude out from the peripheral walls of the shaping rods; and the outer diameter of the positioning blocks is slightly larger than the inner diameter of the shaping channels. Regardless of whether the ear sleeve is matched with the shape of the ear of the user, the outer surface of the ear sleeve in the shaping cavity can be pressed through the positioning ends of the shaping rods on the shaping sleeve, so that the ear sleeve can be tightly attached to the surface of the ear, and therefore, the attachment degree of the ear sleeve and the ear can be improved, and auricular points can be precisely stimulated, and a full stimulation effect can be achieved.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Elastic edge wrapping belt processing technique

ActiveCN107700016AImprove shrinkageFully stereotypedTextile treatment containersHeating/cooling textile fabricsFiberPolyolefin

The invention discloses an elastic edge wrapping belt processing technique. The elastic wrapping belt processing technique includes: preparing a material: selecting elastic polyolefin fibers; and performing loosening retraction, pre-shaping, yarn wrapping, weaving, fabric shaping, fabric dyeing and finishing, post-processing, and drying to acquire the elastic edge wrapping belt. The obtained elastic edge wrapping belt is high in rebound resilience and is low in shrinkage rate.

Owner:中山敦明纺织有限公司

A printing machine strip side pull gauge bending forming device

The invention discloses a printer strip-shaped side pulling gauge bending molding device. The device comprises a base, a rack is arranged on the base, the top face of the rack is provided with a feeding platform and a molding pipeline, the upper portion of the molding pipeline is provided with a cavity, the front portion of the feeding platform is installed in the cavity, the inner circumferentialface of the molding pipeline is provided with a feeding cavity, an electric heating tube is installed in the axial center of the molding pipeline, the surface of the electric heating tube is providedwith an electric heating wire, the inner bottom of the rack is provided with a temperature controlling device, the temperature controlling device is connected with the electric heating wire through acable wire, and the base is provided with an impregnation tank. The device has the advantages that heating molding can be conducted on a bent and molded strip-shaped side pulling gauge, the bending molding efficiency of the strip-shaped side pulling gauge is greatly improved, the impregnation of the strip-shaped side pulling gauge is more sufficient, and the molding is more stable.

Owner:东莞市新生泰印务有限公司

A technological method for eliminating the yin and yang sides of the carpet

ActiveCN110387618BCan't solveGrainy clear and firmArtificial filament heat treatmentMelt spinning methodsYarnTextile printer

The invention mainly discloses a process method for eliminating the yin and yang surfaces of carpets, and its technical scheme: select the matting masterbatch to be diluted to a concentration of 5% to 8%, and use a metering and mixing system to dilute the matting masterbatch to 5% to 8%. It is mixed with the main raw material nylon 6 slices, fed to the screw extruder for heating, melting and extrusion; after the melt passes through the screw extruder, it enters the spinning box for heat preservation, and enters the melt metering pump to accurately measure and enter the spinning assembly. The filaments are formed through the spinneret; air-conditioned blowing is used to cool and form, and then thermally stretched. The temperature of the drafting roller for thermal stretching is 185-200°C, and the speed of the drafting roller is 3000-3200m / min. Roll, after winding, twist 155-165 twists / m, and finally steam setting. With plump and stiff yarns, it completely eliminates the problems of "yin and yang" and "backward wool" of nylon 6 printed carpets.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com