Preparation method of super-soft and super-fine polyester filament yarn

An ultra-fine denier polyester and filament technology, applied in textiles and papermaking, can solve the problems of insufficient softness of the fabric, no polyester filament strands, soft and straight without fluff, etc., and achieve better dimensional stability. Excellent, significant economic benefits, not easy to disperse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

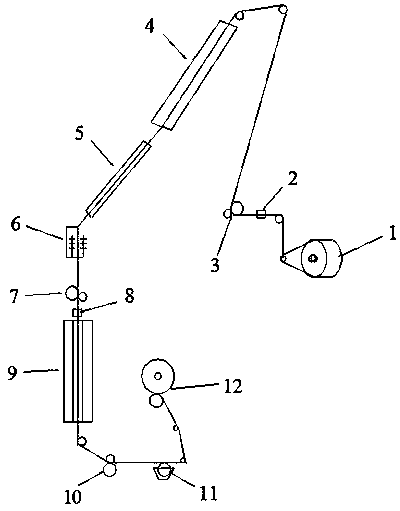

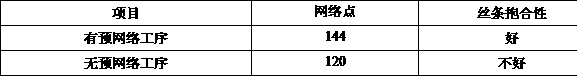

[0019] A preparation method for supersoft and ultrafine polyester filaments provided by the present invention includes: POY raw yarn 1→pre-network 2→first feeding roller 3→first deformation heating box 4→cooling plate 5→false Twister 6→Second wire feeding roller 7→Middle netting 8→Second hot box 9→Third wire feeding roller 10→Oil roller 11→DTY winding forming 12→Silk cake inspection, middle netting 8 process can be removed, The machinery that POY product is processed into DTY product can be the EFK-1000 texturing machine of German BARMAG company, processing speed is 400-800 m / min, the temperature of the first deformation heating box 4 is 160 ℃~200 ℃, the second heating box 9 The temperature is 160°C-180°C, the draft ratio of the false twister 6 is 1.45-2.2, the false-twist speed ratio is 1.45-2.2, the network air pressure is 0.05-0.15MPA, and the second overfeed of the second feeding roller 7 is - 3.0 to 5.0%, the third overfeed of the third feeding roller 9 is -3.0 to 5.0%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com