Method for improving quality of laser metal 3D formed part

A technology of formed parts and laser, which is applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve problems such as unavoidable powder sticking, inability to accumulate thin-walled parts, low energy density, etc., to reduce surface roughness, The effect of reducing surface roughness and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

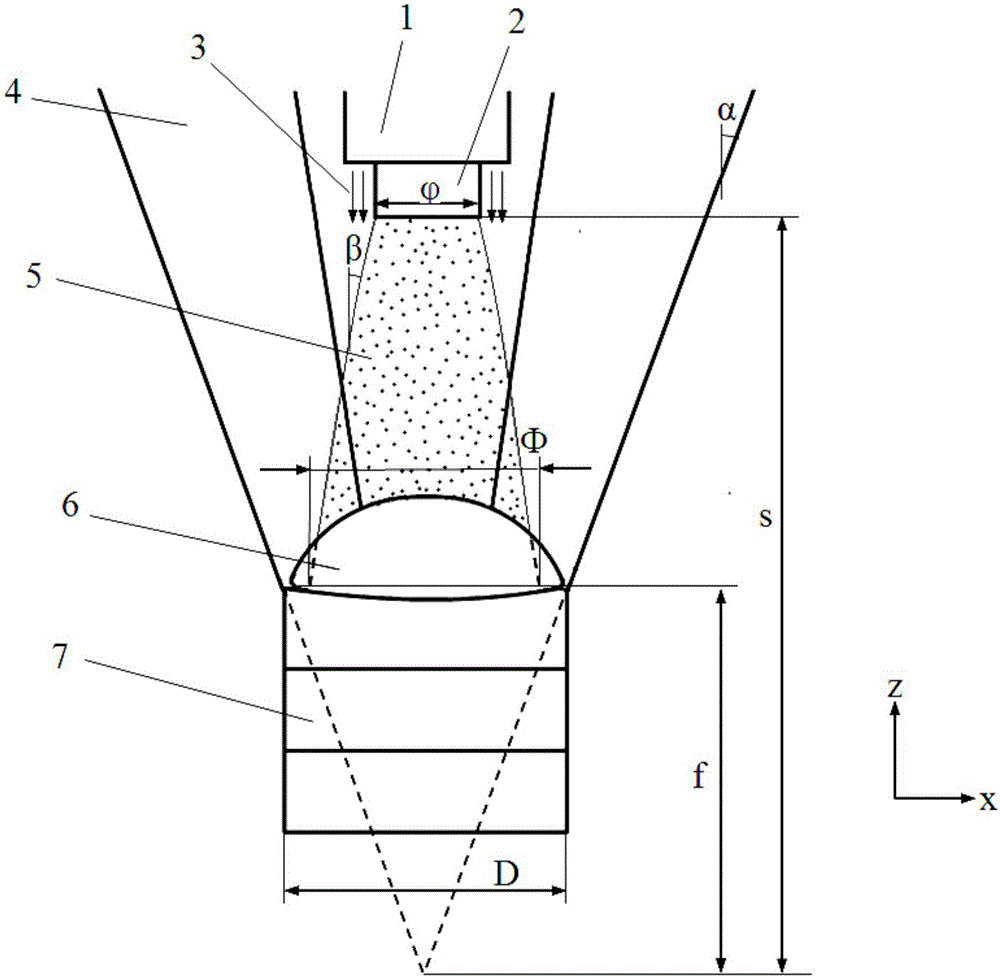

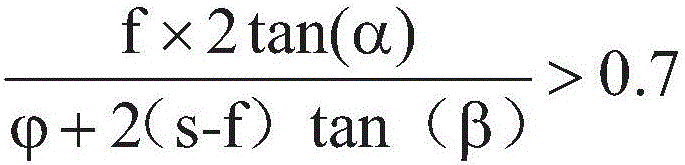

[0024] The powder material is selected as Fe313, the particle size is 75μm-106μm, the laser power is 600W, the powder feeding volume is 8g / min, the scanning speed is 7mm / s, and the protective air pressure is 1.5bar. The parameters of the selected hollow laser cladding nozzle are: s=18mm, α=20°, . The negative defocus amount f is adjusted to 3.5mm, and the measured β value is about 5°. According to the expression D=f×2tan(α) of the outer diameter of the spot, the expression of the powder spot diameter Φ Thus, D:Φ=0.7635>0.7 can be obtained. The average surface roughness of the molded part was measured to be Ra=1.195 μm.

[0025] The present invention adopts the hollow laser internal powder feeding cladding nozzle, the laser beam is distributed in a circular focus, and its scanning energy distribution is saddle-shaped, which is more uniform than the Gaussian distribution, the cladding layers on both sides can be fully melted, and the surface roughness is reduced; The powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com