Sizing device for bulb production

A light bulb production and light bulb technology, applied in the direction of electrical components, etc., can solve the problems of insufficient shaping of the quality of the finished light bulb, and the shaping gas is not easy to be filled into the bulb, so as to achieve reliable continuous transmission and fixation, prevent shaking or even falling off, and have sufficient shaping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

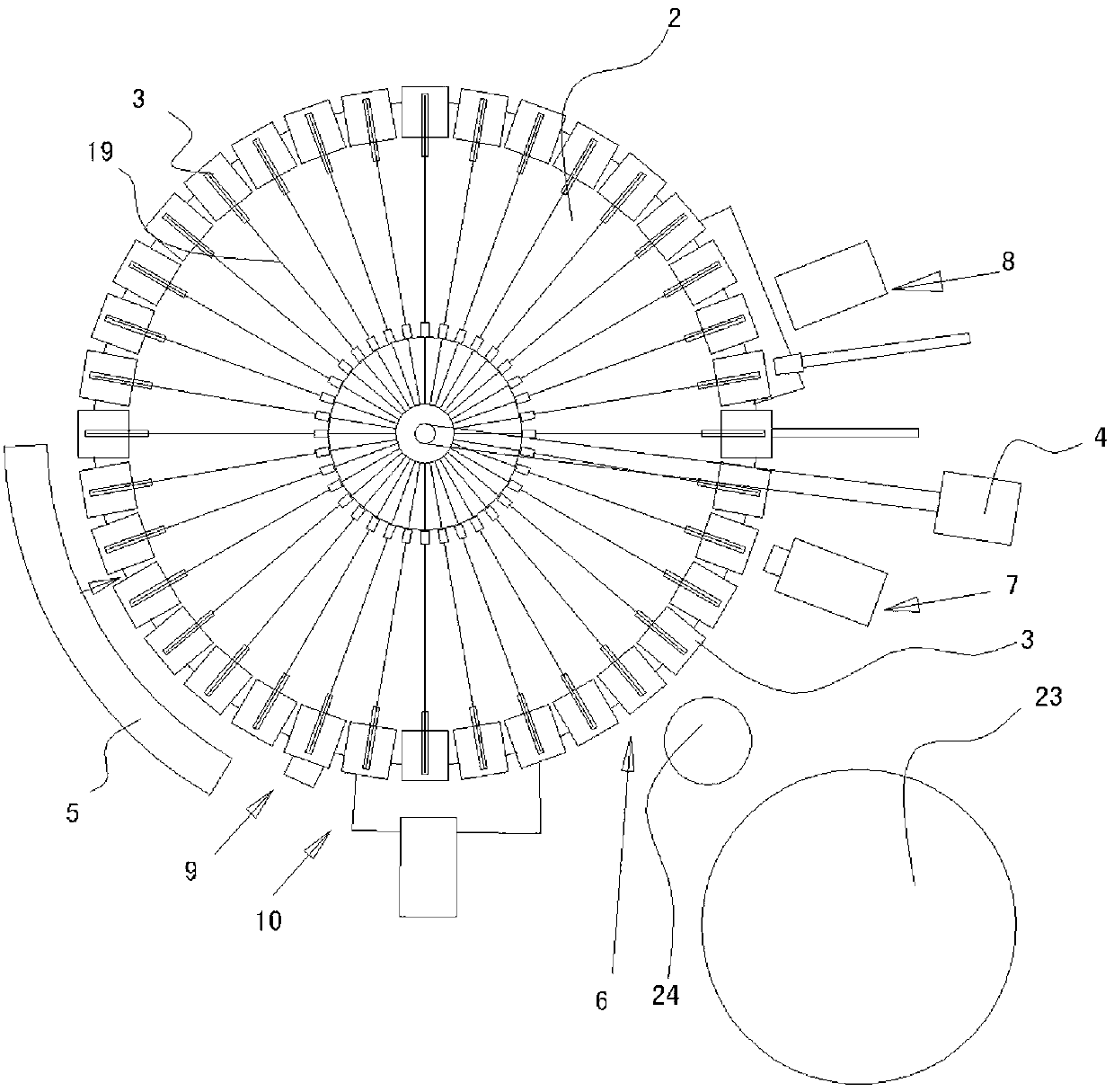

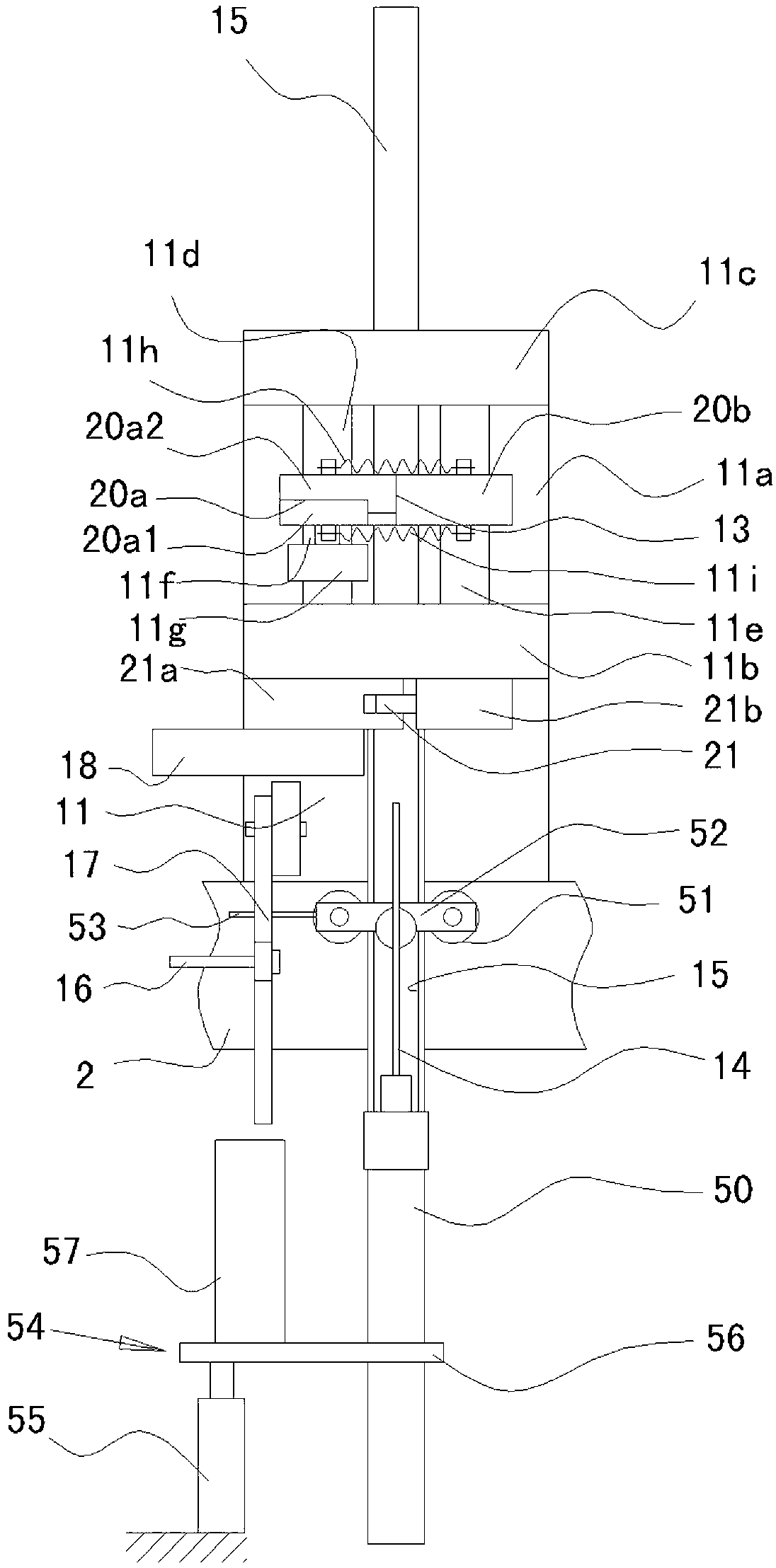

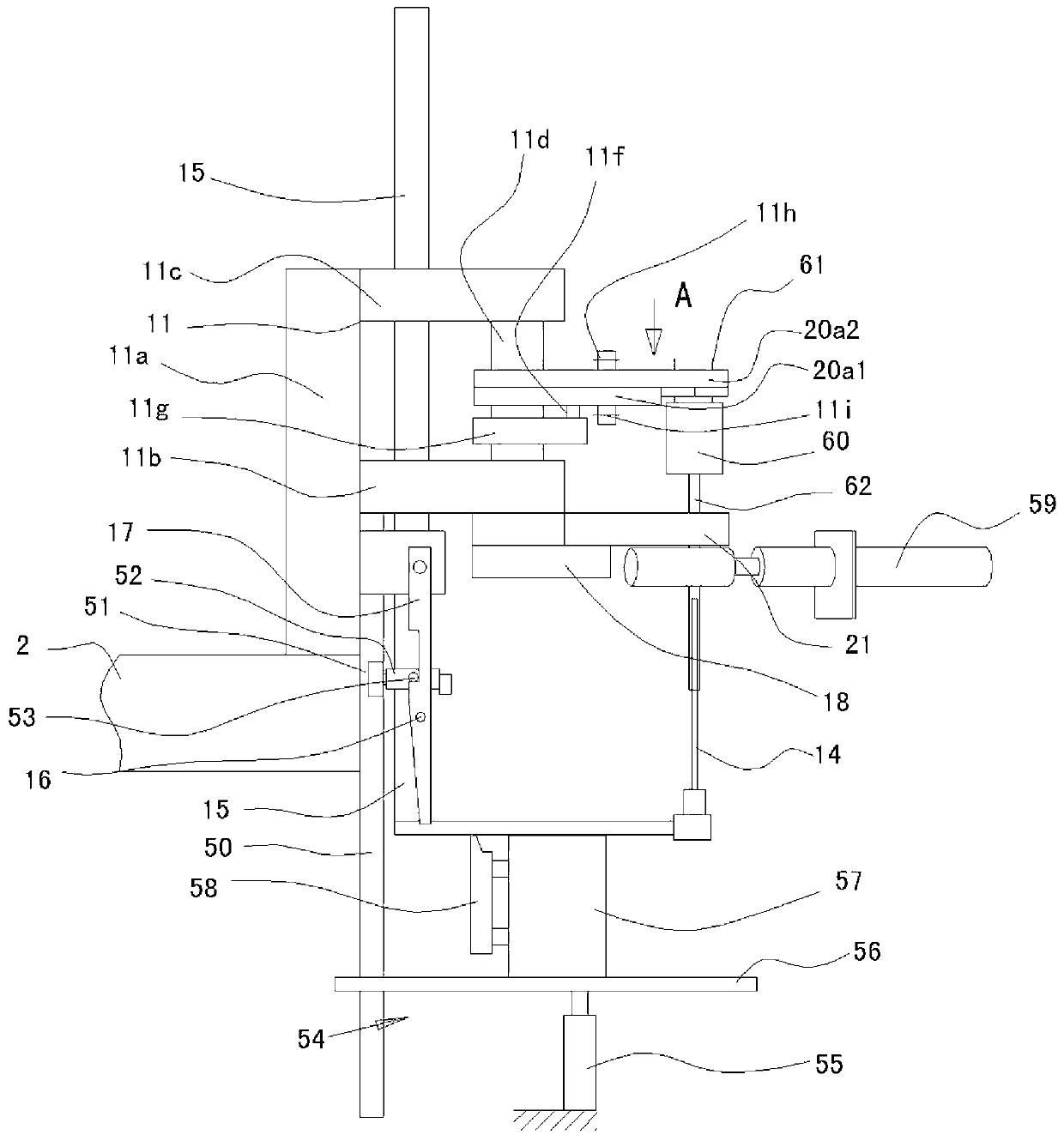

[0024] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0025] Such as figure 1 , 2 , 3, 4, and 5, the present invention includes a frame 1; a turntable 2 arranged on the frame 1 driven by a power mechanism; some bulb clamping / blowing devices 3 arranged along the periphery of the turntable 2; an air source 4; power supply device 5; the upper bulb station 6 with pneumatic propulsion device 59 arranged in turn along the side of the turntable 2 periphery, the station 7 connected to the inflation device, the shaping station 8, the removal of the inflation device station 9, the belt There is a bulb-taking station 10 with a pneumatic pusher 59, and the bulb clamping / blowing device 3 includes a shelf 11 fixed on the turntable 2; the inner side of the chuck 20 arranged on the shelf 11 has a power connector 12 for clamping The bulb clip 13 of the lamp pin 61 of the semi-finished bulb 60; the rod 15 with the blowing no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com